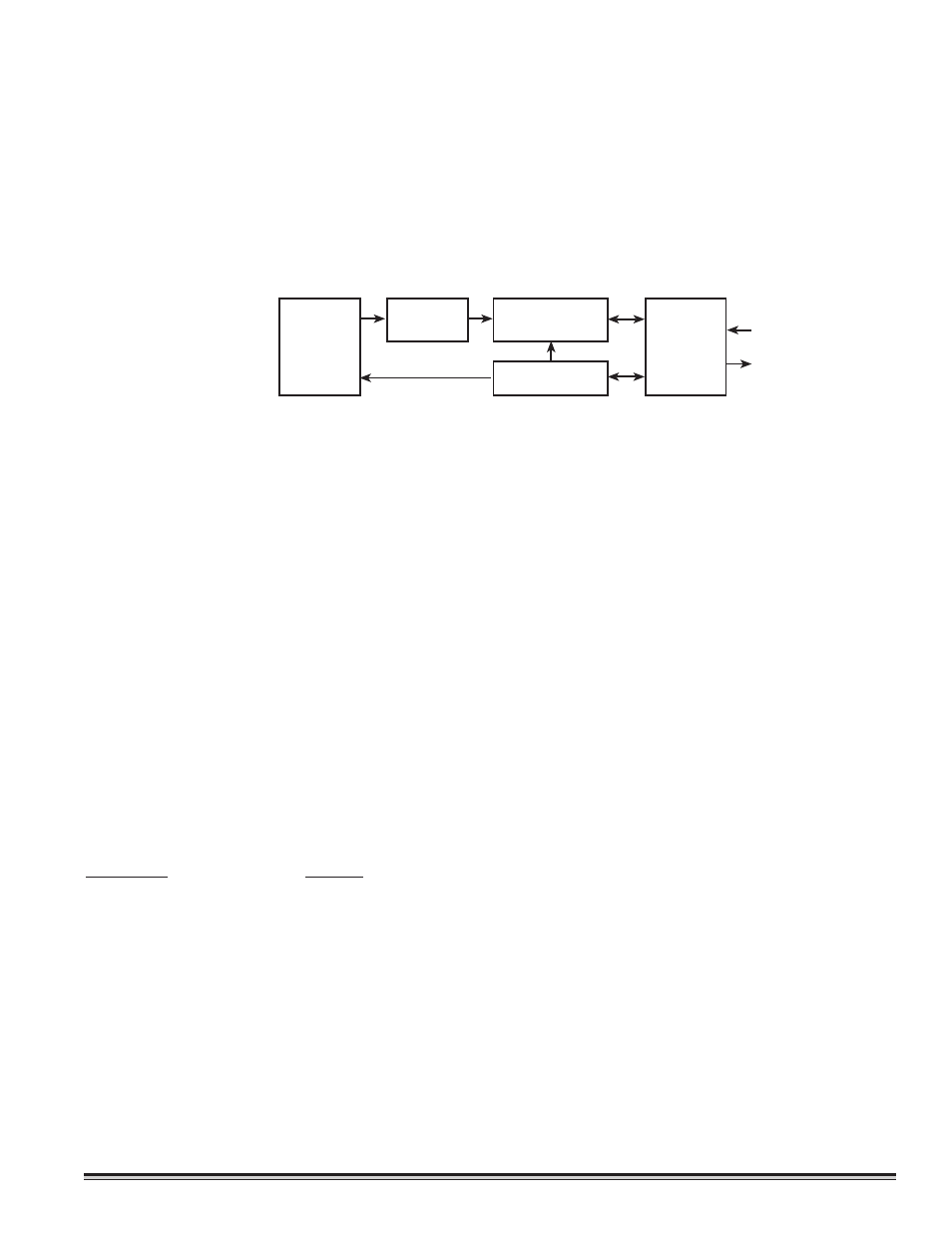

Functional block diagram – Detcon DM-400IS User Manual

Page 6

3.1 P

RINCIPLE OF

O

PERATION

Method of detection is by an electrochemical reaction at the surface of an electrode called the sensing electrode. Air

and gas diffuse through the capillary diffusion barrier. The controlling circuit maintains a small external operating volt-

age between the sensing and counter electrodes of the proper bias and magnitude so that no current f lows to or from

the reference electrode while its potential is maintained at the correct f ixed voltage — usually ground. The electrochemi-

cal reaction creates a change in current f low from the counter electrode to the sensing electrode. This change in current

is proportional to the gas concentration and is reversible. The quick response of the sensor results in continuous moni-

toring of ambient air conditions. The Intrinsically Safe Housing design allows direct contact of the target gas to the

electrochemical sensor, thus maximizing response time, detectability and repeatability.

3.2 A

PPLICATION

3.2.1 Sensor Placement/Mounting

Sensor location should be reviewed by facility engineering and safety personnel. Area leak sources and perimeter mounting

are typically used to determine number and location of sensors. The sensors are generally located 2 - 4 feet above grade.

3.2.2 Interference Data

Detcon Model DM-400IS series electrochemical sensors are subject to interference from other gases. This interaction is

shown in the table in section 3.2.4 as the relation between the amount of the interfering gas applied to the sensor, and

the corresponding reading that will occur. All measurements are in ppm unless otherwise noted.

The table is laid out with the Model Number of each sensor in a column on the left side of the page. The interfering

gases are listed in a row across the top of the page. Each page lists all Model Numbers but 5 pages are necessary to list

all interfering gases, thus each page is a repeat of the full line of Detcon sensors. Be sure to reference each page to ascer-

tain the full listing of interfering gases for a particular sensor.

As an example, the f irst listing shows that the Model DM-400IS-C2H30 acetyldehyde sensor will have an interference

reading of 340 ppm if 40 ppm of C2H2 (Acetylene) is applied.

NOTE: Interference factors may differ from sensor to sensor and with life time. It is not advisable to calibrate with

interference gases. They should be used as a guide only.

3.2.3 Interference Gas List

Gas Name

Symbol

Acetyldehyde

C2H3O

Acetylene

C2H2

Acrylonitrile

C3H3N

Alcohols

Alcohols

Amines

Amines

Ammonia

NH3

Arsenic Trif louride

AsF3

Arsenic Pentaf louride

AsF5

Arsine

AsH3

Boron Trif louride

BF3

Bromine

Br2

Butadiene

C4H6

Buten-1-

Buten-1

Carbon Dioxide

CO2

DM-400IS Toxic Gas Sensors PG.6

Functional

Block

Diagram

4-20 mA +

Sensor

Element

Preamp

I/O Circuit

Protection

4-20 mA –

(11.5-28 VDC)

Transmitter Power

Signal Conditioning

(zero/span)