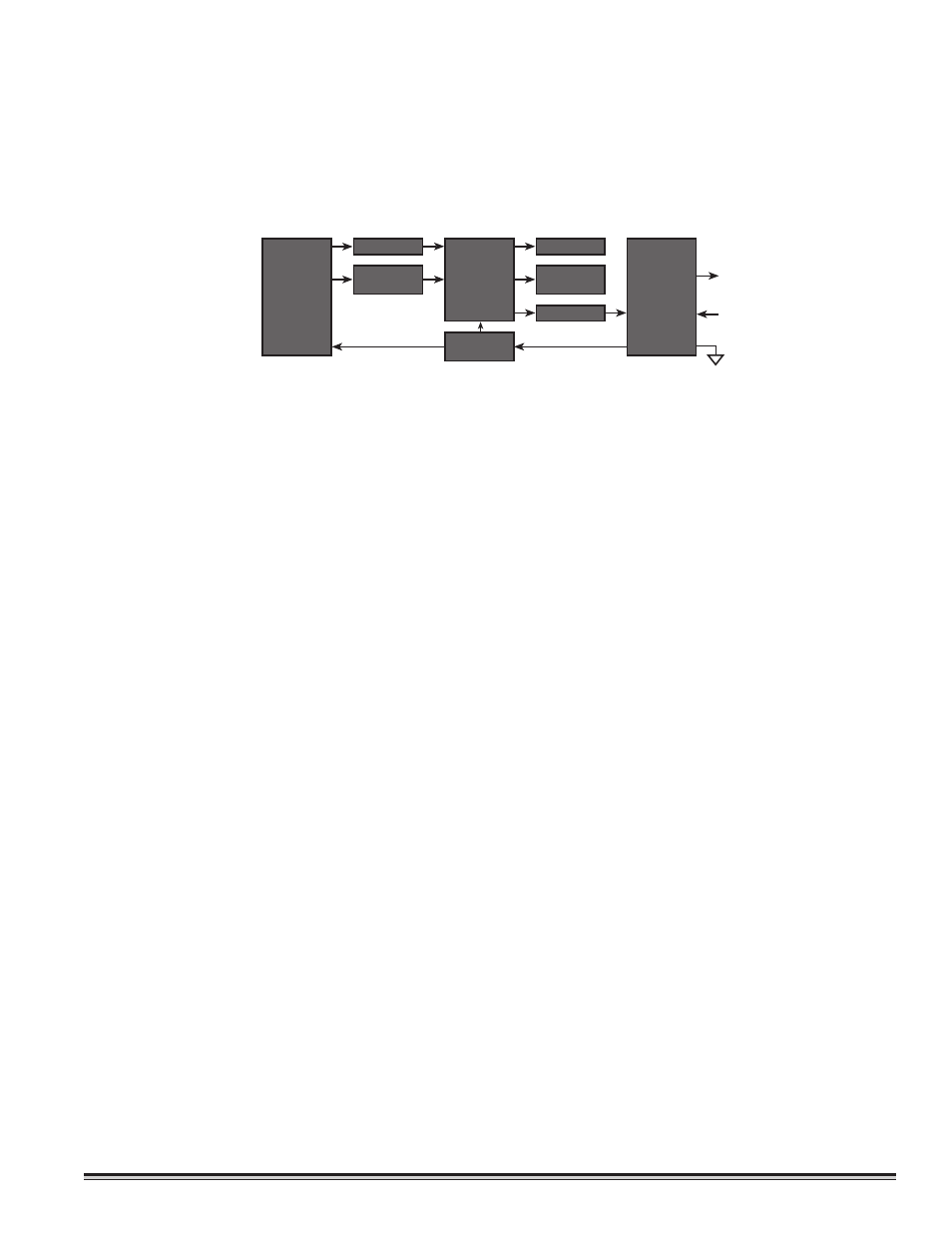

Functional block diagram – Detcon PI-500 User Manual

Page 5

3.1 P

RINCIPLE OF

O

PERATION

Ionizable target gases diffuse into the PID sensor chamber through a sintered f lame arrestor. These target gases are

exposed to UV radiation emitted by the PID lamp and this causes a fraction of the molecules to give up a free electron.

The free electrons are captured by the high voltage collection grid and provide a current signal that is directly propor-

tional to the concentration of the target gas. This change in current is completely reversible and results in the continu-

ous monitoring of ambient air conditions.

3.2 A

PPLICATION

3.2.1 Sensor Placement/Mounting

Sensor location should be reviewed by facility engineering and safety personnel. Area leak sources and perimeter mounting

are typically used to determine number and location of sensors. The sensors are generally located 2 - 4 feet above grade.

3.2.2 Interference Data

Detcon Model PI-500 series PID sensors are subject to interference from many gases. This interaction is shown in the

table in Section 3.2.3. The table shows most all gases of interest and the level of signal response they have relative to a

standard isobutylene reference gas. This measure is referred to as the Response Factor (RF). As a general rule, the lower

the RF value, the stronger the signal from the PID sensor. When determining a cross-interference from one gas to

another, f ind the RF of your target gas and then your interfering gas(es). The cross-interference will be calculated by

dividing the RF of your interfering gas by the RF of your target gas.

For example, if your target gas is benzene and you are concerned about a cross-interference to H2S then you would cal-

culate the cross interference to be 3.3/0.50 = 6.2. This shall be interpreted as: it will take 6.2 ppm of H2S to register as

1 ppm benzene on a PID sensor calibrated for benzene.

In many cases, the user will be interested in measuring a multiple of toxic VOC compounds. In this case the sensor

will produce a signal that is a composite total of each gases’ individual response, when taking into account the corre-

sponding response factors.

For example, if the target gases are benzene and isobutanol and your PID sensor was calibrated for benzene then the

presence of 5 ppm benzene and 5 ppm of isobutanol would each add to the total reading. In this case, the 5 ppm ben-

zene would register as 5 ppm, but the 5 ppm isobutanol would register as the amount of cross interference of isobu-

tanol relative to a benzene calibration. This is calculated as discussed above where you divide the RF of isobutanol by

the RF of benzene. Using the look up table this gives you 3.8/0.50 = 7.2. So it takes 7.2 ppm isobutanol to equal 1

part benzene. Since we have 5 ppm isobutanol, that will equal 0.7 ppm on the benzene scale. The total signal will be 5

+ 0.7 = 5.7 ppm.

3.2.3 Relative Response Gas Matrix (See next page)

The table shows you the response of the PID sensor to a long list of components. It includes the compound name,

synonyms/abbreviations, and chemical formula. It also lists the 10.6 eV Response Factor (the measure of how strong

the signal from the sensor is in reference to Isobutylene gas). Isobutylene gas is the standard reference used with PID

sensors, the lower the Response Factor, the stronger the signal.

NR = not reccomended (does not register)

? = measureable but no data exist

Conf irmed Value = “+” means actual gas has been used to verify RF, “blank” means it is an empirical estimate

IP = is the gases ionization potential (only gases < 10.6eV will respond to sensor)

TWA/Time Weighted Average = generally accepted limit for safe 8 hour exposure (in ppm)

PI-500 Toxic Gas Sensors PG.5

Analog 4-20 mA Out

Functional

Block

Diagram

Power In

Pre-Amp

Display

Temperature

Compensation

Cal & Fault

LEDs

4-20mA

Micro-

processor

Transmitter

Power Supply

Sensor

Element

I/O Circuit

Protection