Additel 938 Hydraulic Pressure Calibration Pump (oil-free) User Manual User Manual

Hydraulic high pressure test pump user's manual, Hydraulic schematic

Warnings and cautions

Specification

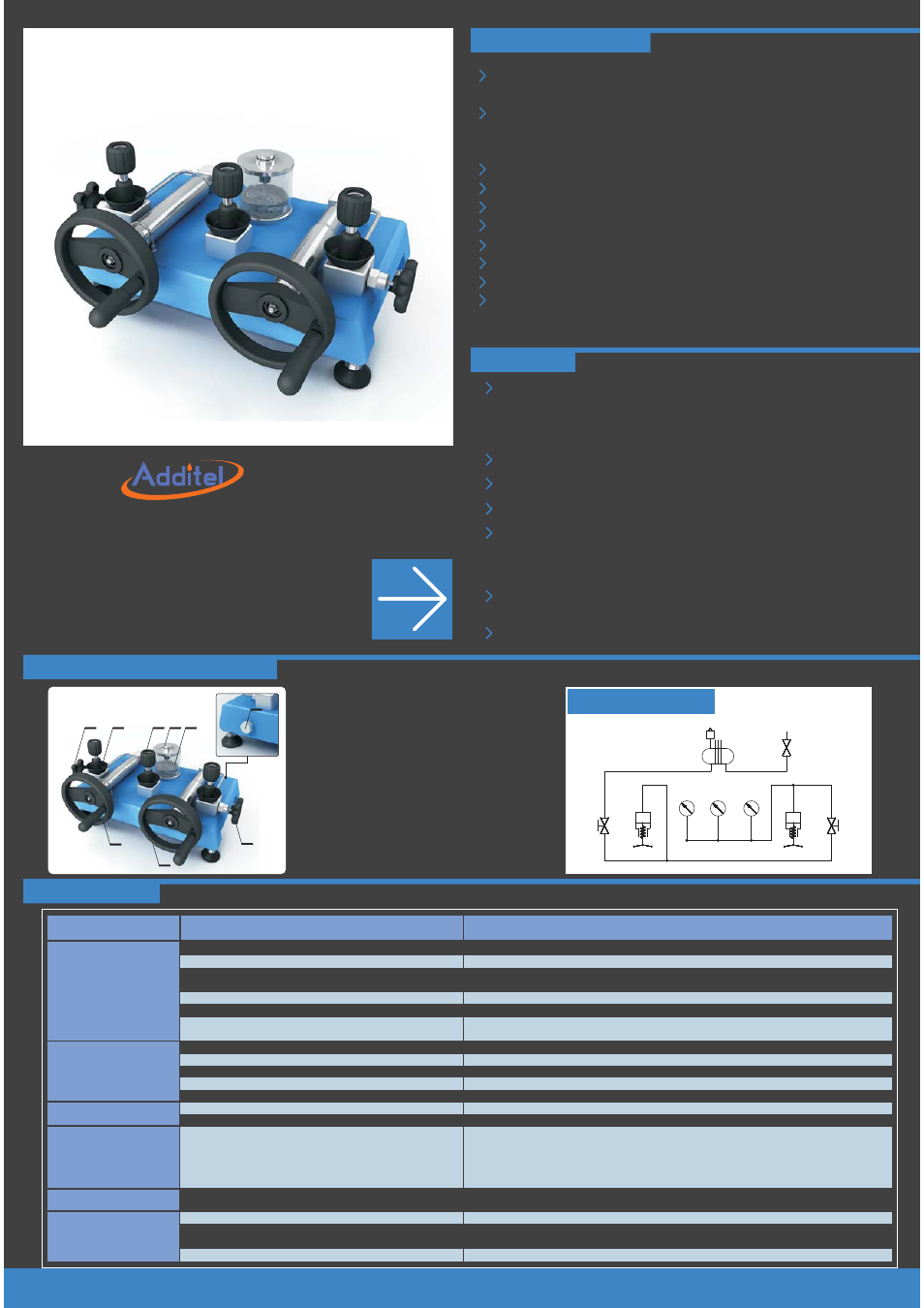

Views and Hydraulic Schematic

Troubleshooting

Hydraulic Schematic

Hydraulic High Pressure Test Pump User's Manual

1- Vent valve

2- Over-flow reservoir

3- Quick connector

4- Reservoir cover vent valve

5- Reservoir

[Version number:1407V02]

936/937/938

It is difficult to generate

pressure with the

pre-pressure

handle (#9)

4

6

1

3

2

7

8

9

5

6- Liquid drain valve

7- Pre-pressure shut off valve

(Isolates the calibration volume from the

pre-pressure side of the pump)

8- High-pressure and fine pressure

adjustment handle

9- Pre-pressure handle

Temperature:

(5 ~ 50)℃

Problem

Cause

Solution

It is difficult to

pressurize by turning

the high-pressure

handle (#8)

Hard to turn the

valves or handles

Hard to pressurize

large-volume DUT

Pressure media:

ADT936: Diethylhexyl Sebacate

ADT938: Deionized water

ADT937 :Oil,compatible to phosphoric acid ester fluid and Skydrol oil.

Pressure range:

12.5 psi ( 0.85 bar ) vacuum to

15,000 psi ( 1000 bar ) positive pressure

Weight:

35.5 lb ( 16 kg )

Adjustment resolution:

0.015 psi ( 1 mbar )

Safety pressure:

<18,000 psi (1,200 bar)

Size:

Height: 10.43'' ( 265 mm )

Base: 20.71'' ( 526 mm ) x 9.65'' ( 245 mm )

1

7

9

8

5

It is difficult to generate

high vacuum

Close vent valve (#1)

Open pre-pressure shut off valve (#7). Caution: the pre-pressure side of the pump should not be exposed to

more than 10,000 psi (700 bar).

Purge the air from the system (see purge section of the manual)

Close pre-pressurization shut off valve (#7)

Replace with a new O-ring

Use proper adapter

Open the #4 valve

Open the #4 valve

This is normal. Close the pre-pressure shut off valve (#7) and use the high-pressure handle to adjust the

pressure.

Replace with a new O-ring

Fill more media, and keep media level between 1/4 and 3/4 of the liquid reservoir filled

Close pre-pressure shut off valve and use high-pressure and handle (#8).

Check finger-tight connectors, re-tight if necessary

Use a PTFE washer in finger-tight connector

Purge the air from the system (see purge section of the manual)

Step 1: Turn pre-pressure handle (#9) all the way in clockwise, close pre-pressure shut off valve (#7),

open vent valve (#1).

Step 2: Turn pre-pressure handle (#9) all the way counterclockwise, close vent valve (#1).

Step 3: Open pre-pressure shut off valve (#7), pressurize the system.

Step 4: Repeat step 1 to 3.

Do not over tighten

Lubricate the threads

Pressure gauges do not

reach to zero

Remark:

If local atmosphere pressure is 1 bar, the vacuum can reach to 0.85 bar;

If local atmosphere pressure is P, the vacuum can reach to

bar.

( P 85% )

Operate the pump in the rated pressure range of 15,000 psi (1,000 bar)

and do not exceed the safety pressure of 18,000 psi (1,200 bar).

When the ystem ressure s reater han 10,000 psi you must close the

pre

ressurization hut ff alve

7

and then pressurize he system with

the high pressure handle.

Close all valves and handles and tighten the ports when transporting the pump.

Always keep the reservoir cover vent valve

#4

open during operation.

Do not over tighten the valves, connectors and handles to avoid damage.

Change media immediately if it is contaminated.

Keep media level between 1/4 and 3/4 of the liquid reservoir filled.

Keep the threads clean and lubricious, and remove any dirt on threads.

Used by trained personnel only.

Additel is not liable for any safety problems or damages caused by misuse

or incorrect operation.

s

p

i g

t

,

-p

s

o v

(# )

t

)

(

Vent (#1) is not closed

Pre-pressure shut off valve (#7) is closed

Too much air is in the pump (see purge section of the manual)

The pre-pressure shut off valve (#7) is not closed completely

The O-ring in quick connector is missing,

, or broken

The connector of the DUT is not matched to quick connector

misplaced

#4 valve is not open

#4 valve is not open

Hard to turn pre-pressure handle (#9) at high pressure

The O-ring in quick connector is missing, misplaced, or broken

Not enough media is in the reservoir.

Max pressure generation (could be as low as 5,000 psi, 350 bar) is

achieved with the pre-pressure handle (#9)

Reference gauge or devices under test (DUTs) are not connected tightly

The end surface of the DUT connection thread is not smooth

Purge the air from the system (see purge section of the manual)

Because of the large volume of the DUT, it will take additional steps to

fill the volume to pressurize the DUT

Too much force was previously applied

Lack of lubrication on threads