Additional operating information – Walker Magnetics CER SERIES User Manual

Page 12

12

O.S. Walker Inc., CER Lift Magnet

: Each Walker magnet model is rated for a different weight limit. Load characteristics will

affect the lifting capacity of the magnets. The lifting guidelines for the various models are shown on the

following pages.

The Lifting Guidelines charts show the effect of air gap, load thickness, load length, and load width on

lifting capacity. As the thickness of the load decreases, so does the rated lifting capacity of the mag-

net. The tables show the maximum weight or load size, which can be lifted for each thickness under

varying air gap conditions. DO NOT EXCEED EITHER THE MAXIMUM WEIGHT OR SIZE FOR

EACH THICKNESS.

Each value shown on the Lifting Guidelines charts is for SAE 1020 steel, and any increase in alloy

content will result in further reduction of the lifting capacity of the magnet.

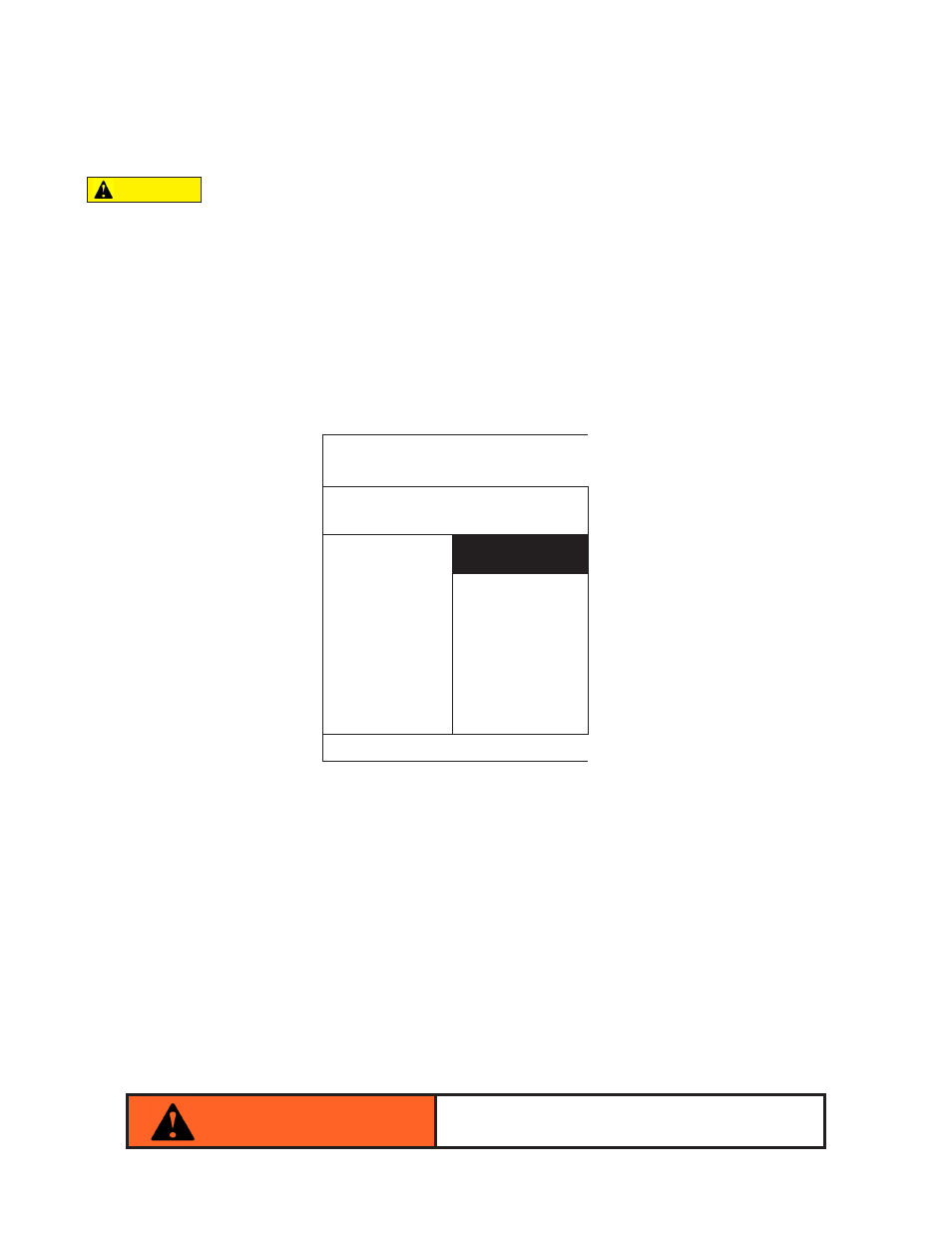

THIS TABLE PROVIDES SOME REDUCTION

FACTORS FOR

MATERIAL OTHER THAN SAE 1020 STEEL

Reduction Factors for Materials

Other than SAE 1020 Steel

Materials

REDUCTION FACTOR

Cast Steel

0.90

3% Silicon Steel

0.80

SAE 1095 Steel

0.70

416 Stainless Steel

0.50

Cast Iron (non-chilled)

0.45

Pure Nickel

0.10

For Other Materials Consult O.S. Walker

CAUTION

If you have any difficulty lifting a load, DON’T LIFT IT!

Call Walker for advice at 1-800-962-4638

WARNING

GUIDELINES FOR THE REDUCTION OF

THE RATED LIFTING CAPACITY:

Rated lift Capacity (For these materials) = Reduction Factor multiplied by Maximum Load Value (For 1020

Steel) from Lifting Guidelines (plate). See page 12.

Example: Lifting SAE 1095 STEEL, ½” thick, ROUGH machined flat surfaces (use .020” air gap) with a Model

CER-9 lifting magnet.

Rated Lift Capacity = 0.70 multiplied by 600 = 420 pounds.

ADDITIONAL OPERATING INFORMATION

Avoid dropping, banging, or slamming the magnet into other objects.

These lifting magnets are electromagnetic devices. Therefore, do not allow water to enter the magnet body. Water is

an electrical conductor and could short out the magnet.

DO NOT EXCEED THE RATED 50% DUTY CYCLE OF THESE MAGNETS. (Exceeding the duty cycle will result in

reduced lifting capacity and a shorter magnet life.) (Refer to Page 14 for definition of Duty Cycle.)