Triangle Engineering of Arkansas JD User Manual

Page 3

temperatures. This is a normal condition, but they may

be hot enough to be painful or injurious to the touch.) If

any problem is indicated, SWITCH OFF IMMEDIATELY.

Lock out the electrical supply and check carefully for the

cause of the trouble and correct as needed. Even if the

fan appears to be operating satisfactorily, shut down after

a brief period and check all fasteners, setscrews and

keys for tightness.

The fan may now be put into operation but during the first

eight (8) hours of running it should be periodically observed and

checked for excessive vibration or noise. At this time checks

should be made on motor input current and motor bearing

temperatures to insure they do not exceed manufacturer’s

recommendations. After eight hours of satisfactory operation,

the fan should be shut down and the electrical power locked

out to check the following items and adjust if necessary:

a. All setscrews, keys and fasteners.

b. Drive coupling alignment.

c. Vbelt drive alignment.

d. Vbelt tension.

NOTE

• Care should be taken to follow all local electrical, safety

and building codes.

• Provisions of the National Electrical Code, as well as the

Occupational Safety and Health Acts should be followed.

• All motors are checked prior to shipment; however, if motor

defects should develop, prompt service can be obtained

from the nearest authorized service station of the Motor

Manufacturer while under warranty. Exchange, repair or

replacement will be provided on a no charge basis if the

motor is defective within the warranty period. The Triangle

Engineering representative in your area will provide a name

and address of an authorized service station if requested.

Do not return defective motors to Triangle Engineering.

WARNING: Motor guarantee is void unless overload

protection is provided in motor wiring circuit.

MAINTENANCE

Do not attempt any maintenance on a fan unless the

electrical supply has been completely disconnected. If a

disconnect switch has not been provided, remove all fuses

from the circuit and lock the fuse panel so they cannot be

accidentally replaced.

Lubrication is a primary maintenance responsibility. All

bearings should be checked periodically. Vbelts also, should

be inspected for tightness. If the fan is installed in a corrosive

or dirty atmosphere, the propeller, inlet and other moving parts

should be cleaned periodically.

MOTOR LUBRICATION: In general, standard motors that

are furnished have prelubricated sealedforlife ball bearings

which require no lubrication for seven to ten years of normal

service. In cases where motors have been ordered with

greasable bearings, these bearings have been lubricated at

the factory and do not require any attention for one year under

normal conditions. If the particular motor is equipped with

grease relief fittings, these should be removed to allow old

grease to flow out when maintenance is performed. Whenever

possible, grease should be applied while the motor is running.

This practice should not supersede any safety consideration.

DO NOT OVER GREASE as most lubricants deteriorate

motor windings, thereby reducing motor life.

FAN SHAFT LUBRICATION: Fan shaft ball bearings are

furnished in either the prelubricated sealedforlife type or

the greasable type depending on what was ordered. Here

again, the prelubricated type requires no servicing for seven

or ten years of normal use, and the greasable type are factory

greased eliminating the need for greasing initially. Whenever

grease is required, depending on the lubricating schedule,

it should be applied while the shaft is rotating. This practice

should not supersede any safety considerations.

IMPORTANT: Use low pressure grease guns only. High

pressure guns tend to blow out or unseat bearing seals, leaving

the bearing open to collect grime, dust and foreign particles.

LUBRICATION SCHEDULE:

a. Under average conditions where ambient temperatures do

not exceed 120°F., lubrication is required once or twice

a year.

b. Under a dirt laden atmosphere where there is a tempera

ture range from 10°F. to 120°F., lubrication is required

from three to six times a year.

c. Under extreme temperature conditions and extremely dirty

atmospheres, lubrication should be scheduled at least

once or twice a month.

PARTS REPLACEMENT: If replacing parts, do so with

properly selected components, which duplicate original parts

correctly. Incorrectly sized shafts, belts, pulleys, propellers,

etc. can damage the fan.

SPECIAL PURPOSE SYSTEMS

Explosive, corrosive, high temperature, etc. conditions may

require special construction, inspection and maintenance. It is

necessary to observe the fan manufacturer’s recommendations

and limitation concerning the type of material to be handled by

the fan and its application to special conditions.

THE HIDDEN DANGER

In addition to the normal dangers of rotating machinery,

fans present an additional hazard in their ability to suck in

not only air, but loose material as well. Solid objects can

pass through the fan and be discharged by the propeller as

potentially dangerous projectiles. Intake to duct work should,

whenever possible, be screened to prevent the accidental

entrance of solid objects.

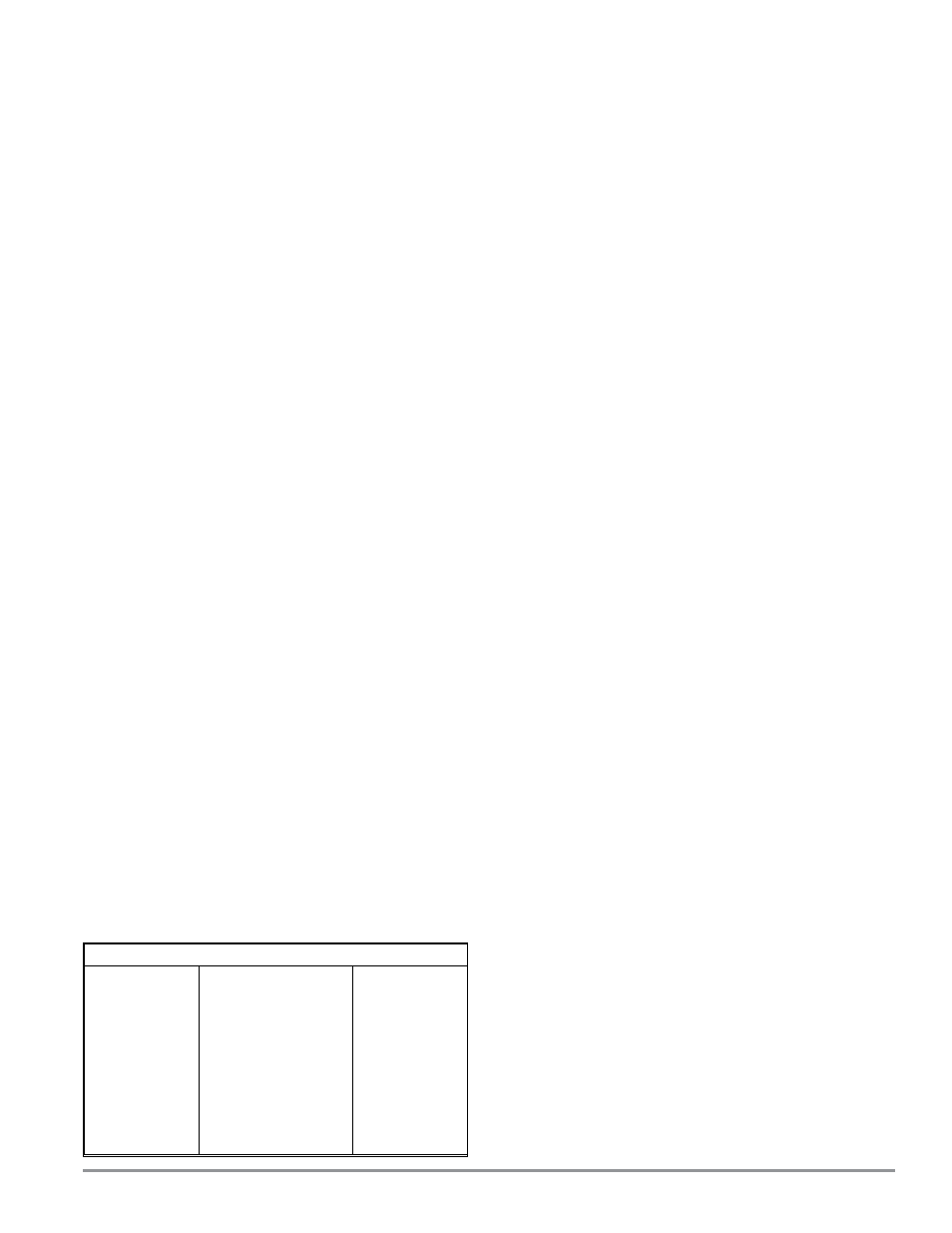

RECOMMENDED LUBRICANTS

MANUFACTURER

Chevron

Gulf

Imperial Oil

Shell

Sun Oil

Texaco

Gulf

Imperial Oil

Shell

Sun Oil

Texaco

PRODUCT NAME

SRI-2

Gulfcrown EP-1

Unirex EP-1

Alvania R-2

Sunaplex IEP

Regal AFB2

Gulfcrown EP-2

Unirex EP-2

Alvania R-3

Sun Prestige 42 grease

Regal AFB-2

TEMP. RANGE

Below

32°F. (0°C)

Range 32°F to

150°F (0°C to

66°C)