Triangle Engineering of Arkansas FHI SERIES PANEL FANS Propeller Installation User Manual

Installation instructions

INSTALLATION INSTRUCTIONS

For Sound Fighter Fan

tM

ProPellerS

equiPPed with SPlit taPer BuShingS

SeCtion i:

general inForMation

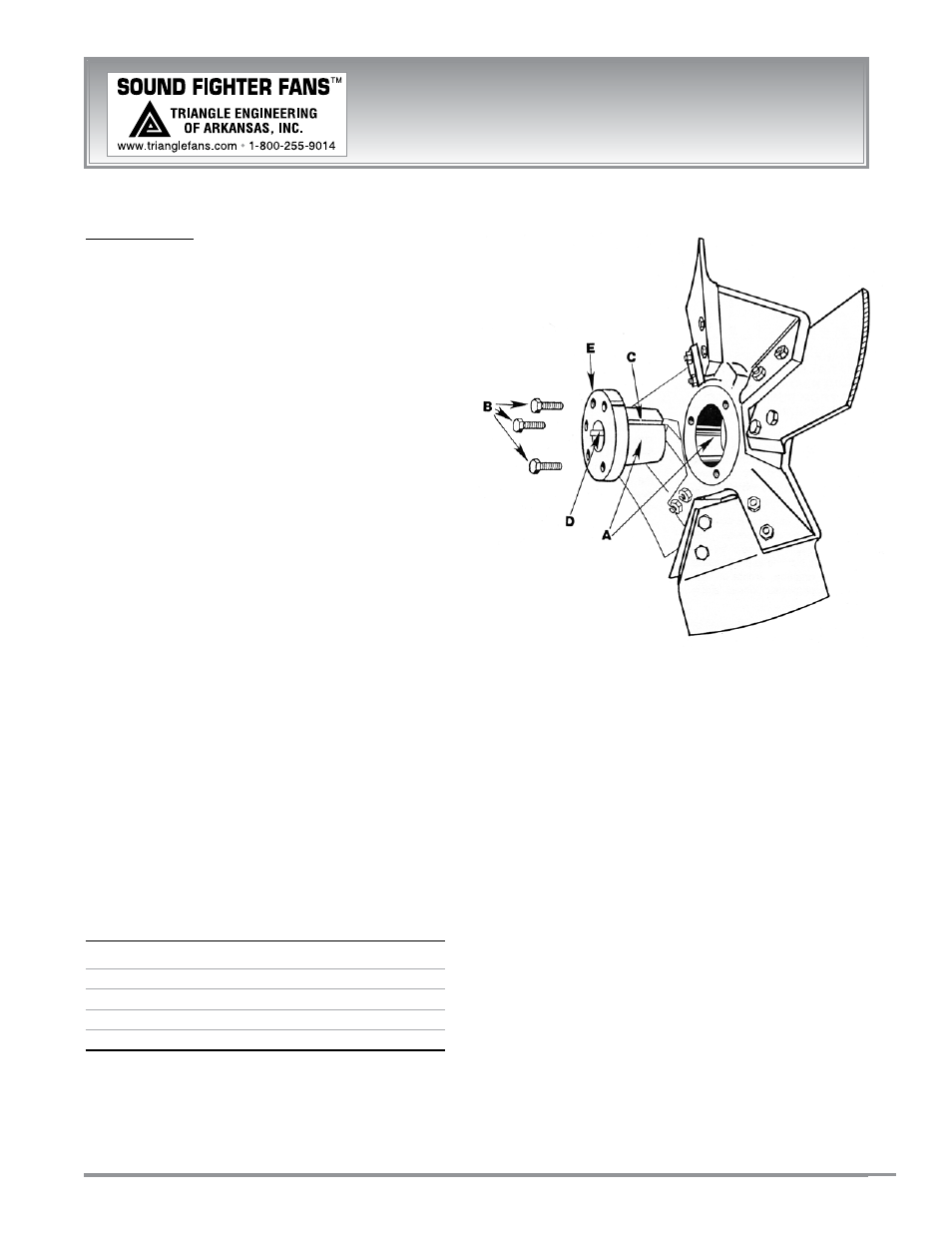

1. airFoil ProPeller and BuShingS

SoundFighterFans™castaluminumairfoil

propellersarefurnishedwithsplittaperlock

bushingsformountingthepropellertotheshaft.

Whenproperlypositioned,thebushinggripsthe

hubwithapositiveclampingaction.Theflangeis

boltedtothefanhubtosecurethefan,andwhen

theboltsaretightened,thetaperedsurfaceofthe

splitbushingiscompressedaroundtheshaft.

2. inStalling aSSeMBlY oF ShaFt

Thefirststepininstallingataperedbushing

istothoroughlycleantheshaft,theboreand

exteriorofthebushing,andthetaperedbore

ofthecomponent.Nicks,burrs,dirt,andchips

shouldberemoved,sincetheycancausealoss

ofconcentricityandevengrippingstrength.The

housingshouldbeinsertedintothehubwithit’s

holesmatchedwiththehub’sholes.Thecap-

screwsshouldbeinsertedintheholesthatare

threadedonthehubside.Thepropellershould

thenbemountedontheshaft,withthebushingin

place,andthecapscrewstightenedtothetorque

valuesshownbelow.

3. noteS on CorreCt aSSeMBlY

A.Bushingbarrelandboreofpropelleraretapered

-thisassuresconcentricmountingandatrue

runningpropeller.

B.Capscrews,whentightened,lockbushingin

propeller.Usecapscrewsthreadedfulllength.

BuShing

diaMeter

length

torque

no.

(Ft.lBS.)

H

1/4-20

1"

6

P

5/16-18

1-1/4"

13

Q

3/8-16

2"

2

SD

1/4-20

1"

6

SK

5/16-18

1-1/4"

13

Caution:MAKESURECAPSCREW

LENGTHSMATCHTRIANGLEENGINEERING’S

RECOMMENDATIONS.SHORTERCAPSCREWS

FROMBUSHINGMANUFACTURERAREDESIGNED

FORCASTIRON,NOTALUMINUM.

C.Bushingissplitsothatwhenthelockingcapscrews

forcethebushingintothetaperedbore,the

bushinggripstheshaftwithapositiveclampingfit

-thiswillwithstandvibrationandpunishingloads

withoutbeingloosened.

D.Propellerandbushingassemblyiskeyedtoshaft

andheldinplacebycompression-thisgives

addeddrivingstrength.Theuseofanoptional

keyforsecuringthebushingtothepropellerhub

isgenerallynotrequired,exceptonhighspeed,

hightorqueapplications.Contactfactoryfor

recommendations.

E.Propelleriseasilyremovedfromtheshaftby

insertingandtighteningtwoofthecapscrewsinto

thetappedholesinthebushingflange-thisforces

thebushingloosefromthepropellerandreleases

thecompressionsothattheentireassemblywill

slidefromtheshaft.

Flangedtapered

bushingboltstohub.

Extraboltholesare

usedtofacilitate

removal.Flangeshould

notbehammered.