Triangle Engineering of Arkansas VID SERIES (Direct Drive) User Manual

Page 3

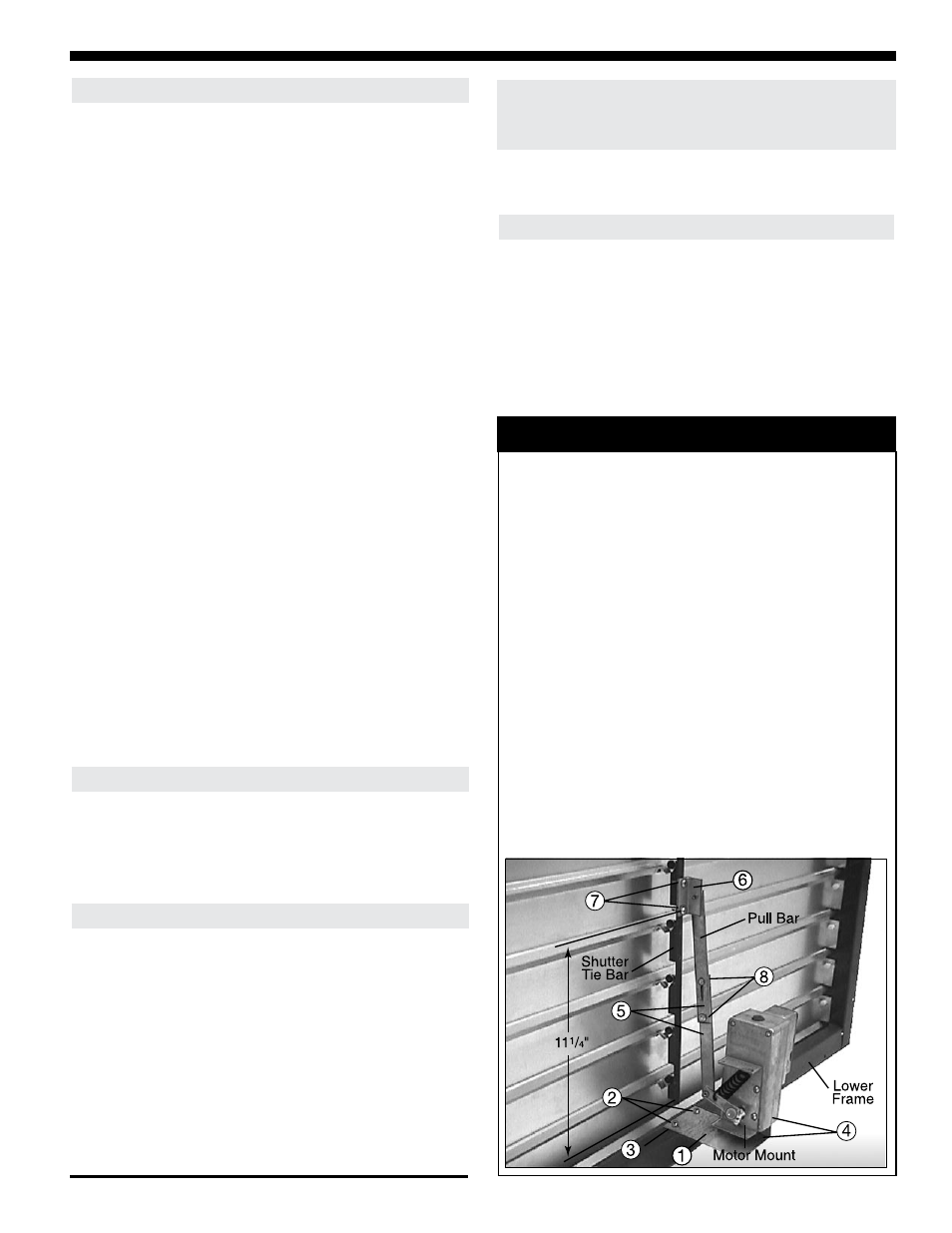

1. Remove shutter motor mounting bracket from motor

assembly.

2. Center mounting bracket on centerline of lower frame.

Use motor mounting plate as a template to locate and

drill three holes at

5

⁄

32

" dia. thru.

3. Attach motor mounting bracket to the top and the back

surfaces of the lower fame by using (qty 3) #8 x

3

⁄

4

" self

drilling screws.

4. Re-attach shutter motor to mounting bracket.

5. Assemble pull bar arms to the middle of their adjustment

slots and tighten firmly.

6. Locate the center of the bottom screw hole in the pull bar

bracket 11

1

⁄

4

" from the bottom of the shutter tie bar as

shown. Use bracket to locate & drill 2 holes

5

⁄

32

" diam.

7. Attach the pull bar bracket to the tie bar by using (qty. 2)

#8 x

1

⁄

2

" self drilling screws.

8. Readjust pull bar adjustment slots to create a firm seal

between the shutter blades.

Page 3

PREPARATION

1. Inspect the area where the fan is to be installed. The area

must be free of ANY wiring and plumbing.

2. PLAN FOR WIRING. Insure that the fan wiring is com-

patible to the building wiring. Check and note the motor

wiring BEFORE INSTALLATION.

3. PLAN FRAMING AND INSTALLATION.

• Add 1/4" to the width and height of the fan housing. These

dimensions will be the INSIDE measurements of the fram-

ing.

• Plan the installation so that the fan blade is at least 6" from

the shutter. (See Page 2)

4. MASONRY STRUCTURE

• Plan the opening in the exterior wall so that block or brick will

be clear of the shutter frame.

• Plan for an angle-iron header to support the block or brick.

• Use "C" Channel or 2" x lumber to construct the framing and

header for the fan.

• Follow Local Building Codes to plan the construction of the

framing and header.

5. WOOD STRUCTURE

• Plan the opening in the exterior wall so that the building sid-

ing will overlap the shutter frame lip, and that the shutter will

be mounted to the framing. (See Fig. 1& 2)

• Use 2" x lumber to construct the header in accordance

with local codes.

• Use sheet metal screws to mount the fan and shutter.

6. STEEL STRUCTURE

• Plan the opening in the exterior wall so that the building sid-

ing will overlap the shutter frame lip. (See Fig. 3 & 4)

• Use a "C" Channel for the fan frame.

• Use self tapping or sheet metal screws to attach the shutter.

• Use self tapping screws or machine bolts with lock washers

to mount the fan.

CONSTRUCTION

1. Following all of the Building Codes for your area, cut the

opening, and construct the framing and header.

2. Install the wiring needed for the fan. If an Electric Shutter

Operator is to be installed, run the wiring at this time.

NOTE: The Operator Uses Only 115/230/60/1 Current.

INSTALLATION

1. INSTALL THE SHUTTER.

• Check to make sure the shutter is installed level and square.

• DO NOT tilt or twist the shutter frame.

• Manually operate the shutter. It should move freely without

bind or drag.

2. REPLACE AND RE-FASTEN THE SIDING.

• Caulk all four exterior sides of the shutter.

3. If an Electric Shutter Operator (IWS 3187 or IWS 887) is

to be utilized, install and wire it at this time. (See Fig. 5)

4. IMPORTANT! Install the fan with a minimum of 6"

between the fan blade and the shutter.

5. INSTALL THE WIRING.

• Check the motor label, the motor connections, and the

input power to insure proper installation and rotation.

6. Optional fan guard needs to be installed if the bottom of

the fan is less than 7ft above the floor. This is an OSHA

requirement.

TESTING

1. APPLY POWER TO THE FAN.

• As an EXHAUST FAN the blade assembly should rotate

Counter-Clockwise, when viewed from the motor side of

the fan.

• Test the operation of the Electric Shutter Operator.

• Observe the shutter. It should operate freely.

ELECTRIC SHUTTER OPERATOR

Fig. 5