Assembly of heavy-duty boltless rack – Tennsco Z-Line Heavy Duty Boltless Rack User Manual

Page 2

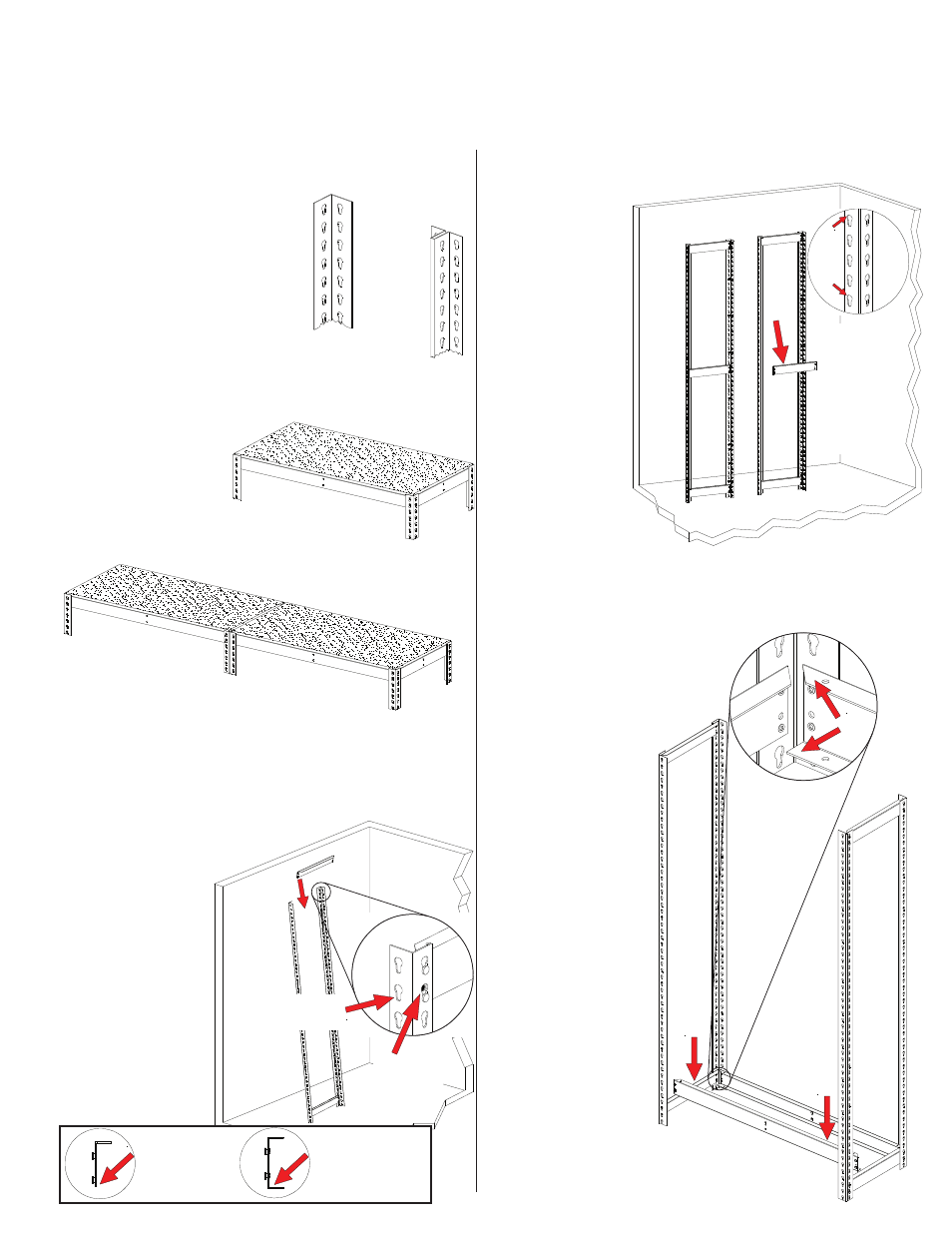

Tools Needed: A rubber mallet for seating the shelf supports. Two people are recommended for assembly.

Approximate assembly time: 15 to 30 minutes per section.

ASSEMBLY OF HEAVY-DUTY BOLTLESS RACK

4.

Place a third front-to-back end support in the

middle keyholes of the two uprights

(or at whatever

level you want

your third shelf

to be). This

forms one

end of the

shelving unit.

5. Repeat steps

3 and 4 to

construct a

second set

of unit ends.

NOTE: If you

are planning to

install an adder unit,

this second set should consist of ZTP uprights

(Ref. No. 1b) to act as an intermediate assembly.

Carefully re-read through step 2 to better

understand this.

2.

Depending upon whether you

are assmebling a single unit or

an adder unit, you may have

one or both of the styles of

upright shown at right:

"T" Post

(ZTP)

B. Two or more units with High Capacity Posts

(SUR) on each end and "T" Posts (ZTP) as

intermediate posts.

1.

The reference numbers used throughout this sheet

refer to the illustration on the back cover. This is to

help you to identify the various

parts as they are mentioned.

LEFT-TO-RIGHT

SUPPORT (LRC) has

an added flange at the

bottom for strength.

A single unit uses SUR posts for all four uprights,

as shown below in Figure A. If you plan on

assembling mulpitle sections, however, you should

build your starter unit

with two ZTP posts

on one end, which

will provide common

posts for adjacent

sections, as shown

in Figure B.

FRONT-TO-BACK

SUPPORT (LRA)

has no flange at

the bottom.

6.

With the help of an

associate, connect

the two unit ends

with left-to-right

channel beams

(Ref. No. 3). If the

top flange on the

front-to-back end

support interferes

with the top flange

on the channel

beam, your

channel beam is

upside-down.

The flange with

the angled ends

must be on top,

as shown at right.

Be sure that the

channel beams

are fully seated,

as was illustrated

in step 3.

High Capacity

Post (SUR)

A. Single unit with four

High Capacity Posts (SUR).

3.

With help from an associate, or using a wall for

support, connect two SUR uprights (Ref. No. 1a)

together with two front-to-back supports (Ref. No.

2), one at the top and one near the bottom (you

should leave the bottom keyhole

slot empty). Be sure the

supports are fully

seated in the slots,

as shown at right.

NOTE: Front-to-

back supports are

different than left-

to-right supports.

Be sure you are

using the correct

supports on the

ends, as shown

in the box below.

ZTP

SUR

SUR

NOTE: Inset is

shown from

opposite side.

Supports are

properly seated

when alignment

hole is fully visible

Narrow area

of keyhole slot

is at bottom

Every 4th hole

is flattened at top

NOTE: Every

fourth keyhole

slot is shaped

differently (with

a flattened top)

for easier

alignment of

supports, as

shown above.

Proper orientation

of channel beam:

Flange with angled

end is on top;

Flange with flat

end is on bottom.

LRA

LRC