Sa25, Msa1 & msa25, Flap-valve – SANDPIPER MSA25 User Manual

Page 4: Materials

msa1dl4sm-rev0711

Model MSA1, MSA25 Type 4 Page 3

SA1

&

SA25

Copyright© 2009 IDEX AODD, Inc. All rights reserved. Specifications are subject to improvement without notice. ®Warren Rupp and SANDPIPER® are registered tradenames of IDEX AODD, Inc.

sa1dl4ds-REV1009

FLAP-VALVE

Maximum* Minimum*

Optimum**

Operating Temperatures

MATERIALS

190 °F

-10°F

5 0°F to 140 °F

88 °C

-23°C

1 0°C to 60 °C

NEOPRENE All purpose. Resistant to vegetable oils. Generally not affected by moderate

chemicals, fats, greases and many oils and solvents. Generally attacked by strong oxidizing acids,

ketones, esters, nitro hydrocarbons and chlorinated aromatic hydrocarbons.

NITRILE General purpose, oil-resistant. Shows good solvent, oil, water and hydraulic fluid

resistance. Should not be used with highly polar solvents like acetone and MEK, ozone,

chlorinated hydrocarbons and nitro hydrocarbons.

170 °F

-35°F

5 0°F to 130 °F

77 °C

-37°C

1 0°C to 54 °C

FKM (Fluorocarbon)

Shows good resistance to a wide range of oils and solvents; especially all

aliphatic, aromatic and halogenated hydrocarbons, acids, animal and vegetable oils. Hot water or hot

aqueous solutions (over 70 ° F) will attack FKM.

212 °F+

+32°F

7 5°F to 212 °F

100 °C+

0 °C

2 4°C to 100 °C

212 °F+

-10°F

5 0°F to 212 °F

100 °C+

-23°C

1 0°C to 100 °C

EPDM Shows very good water and chemical resistance. Has poor resistance to oil and solvents,

but is fair in ketones and alcohols.

STAINLESS STEEL CF-8M equal to or exceeding ASTM specification A743 for corrosion resistant iron chr

omium, iron chromium nickel,

and nickel based alloy castings for general applications. Commonly referred to as 316 Stainless Steel in the pump industry.

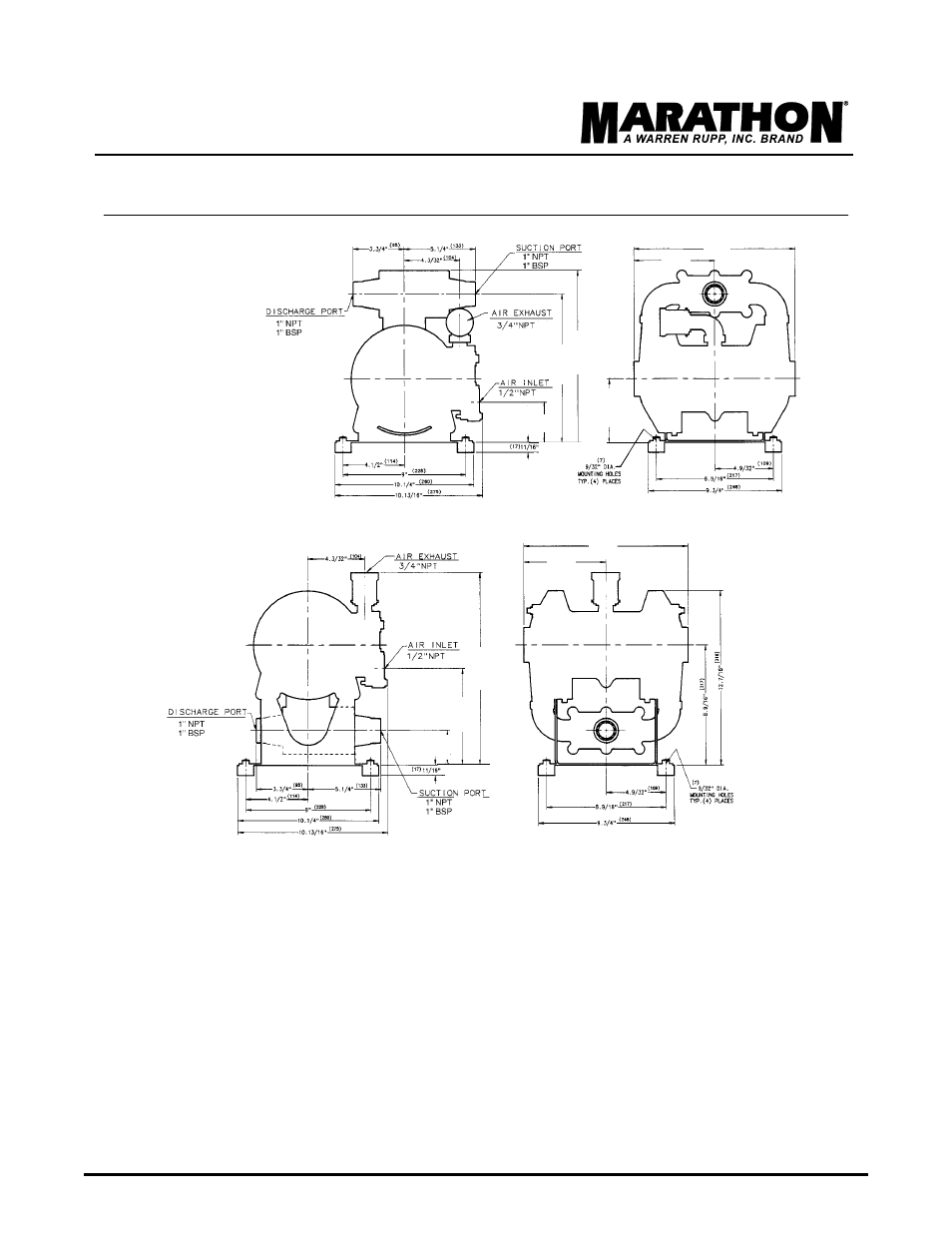

Dimensions are 1/8"

Figures in parenthesis = millimeters

*Definite reduction in service life.

**Minimal reduction in service life at ends of range.

For specific applications, always consult The Warren Rupp Chemical Resistance Chart.

Model MA1 features

NPT threaded connections.

Model MA25 features

British Standard Pipe

(BSP) Tapered threaded

connections.

Tapered

Tapered

10.

11/16"

(272)

12.

3/8"

(314)

4.

5/8"

(117)

2. 15/16"

(75)

11. 1/4"

(286)

5. 5/8"

(143)

11. 1/4"

(286)

5. 5/8"

(143)

Tapered

Tapered

2. 1/2"

(64)

6.

15/16"

(176)

15.

3/4"

(400)

WARREN RUPP

®

, IDEX AODD, INC. • A Unit of IDEX Corporation • P.O. Box 1568, Mansfield, Ohio 44901-1568 USA

Telephone (419) 524-8388 • Fax (419) 522-7867 • www.warrenrupp.com

Optional Rubber Feet

SA1

&

SA25

Copyright© 2009 IDEX AODD, Inc. All rights reserved. Specifications are subject to improvement without notice. ®Warren Rupp and SANDPIPER® are registered tradenames of IDEX AODD, Inc.

sa1dl4ds-REV1009

FLAP-VALVE

Maximum* Minimum*

Optimum**

Operating Temperatures

MATERIALS

190°F

-10°F

50°F to 140°F

88°C

-23°C

10°C to 60°C

NEOPRENE All purpose. Resistant to vegetable oils. Generally not affected by moderate

chemicals, fats, greases and many oils and solvents. Generally attacked by strong oxidizing acids,

ketones, esters, nitro hydrocarbons and chlorinated aromatic hydrocarbons.

NITRILE General purpose, oil-resistant. Shows good solvent, oil, water and hydraulic fluid

resistance. Should not be used with highly polar solvents like acetone and MEK, ozone,

chlorinated hydrocarbons and nitro hydrocarbons.

170°F

-35°F

50°F to 130°F

77°C

-37°C

10°C to 54°C

FKM (Fluorocarbon)

Shows good resistance to a wide range of oils and solvents; especially all

aliphatic, aromatic and halogenated hydrocarbons, acids, animal and vegetable oils. Hot water or hot

aqueous solutions (over 70° F) will attack FKM.

212°F+

+32°F

75°F to 212°F

100°C+

0°C

24°C to 100°C

212°F+

-10°F

50°F to 212°F

100°C+

-23°C

10°C to 100°C

EPDM Shows very good water and chemical resistance. Has poor resistance to oil and solvents,

but is fair in ketones and alcohols.

STAINLESS STEEL CF-8M equal to or exceeding ASTM specification A743 for corrosion resistant iron chr omium, iron chromium nickel,

and nickel based alloy castings for general applications. Commonly referred to as 316 Stainless Steel in the pump industry.

Dimensions are 1/8"

Figures in parenthesis = millimeters

*Definite reduction in service life.

**Minimal reduction in service life at ends of range.

For specific applications, always consult The Warren Rupp Chemical Resistance Chart.

Model SA1 features

NPT threaded connections.

Model SA25 features

British Standard Pipe

(BSP) Tapered threaded

connections.

Tapered

Tapered

10.

11/16"

(272)

12.

3/8"

(314)

4.

5/8"

(117)

2. 15/16"

(75)

11. 1/4"

(286)

5. 5/8"

(143)

11. 1/4"

(286)

5. 5/8"

(143)

Tapered

Tapered

2. 1/2"

(64)

6.

15/16"

(176)

15.

3/4"

(400)

WARREN RUPP

®

, IDEX AODD, INC. • A Unit of IDEX Corporation • P.O. Box 1568, Mansfield, Ohio 44901-1568 USA

Telephone (419) 524-8388 • Fax (419) 522-7867 • www.warrenrupp.com

Optional Rubber Feet

MSA1 &

MSA25

Model MSA1 features NPT

threaded connections.

Model MSA25 features

NPT threaded connections.