Assembly – RIKON Power Tools 10-346 User Manual

Page 10

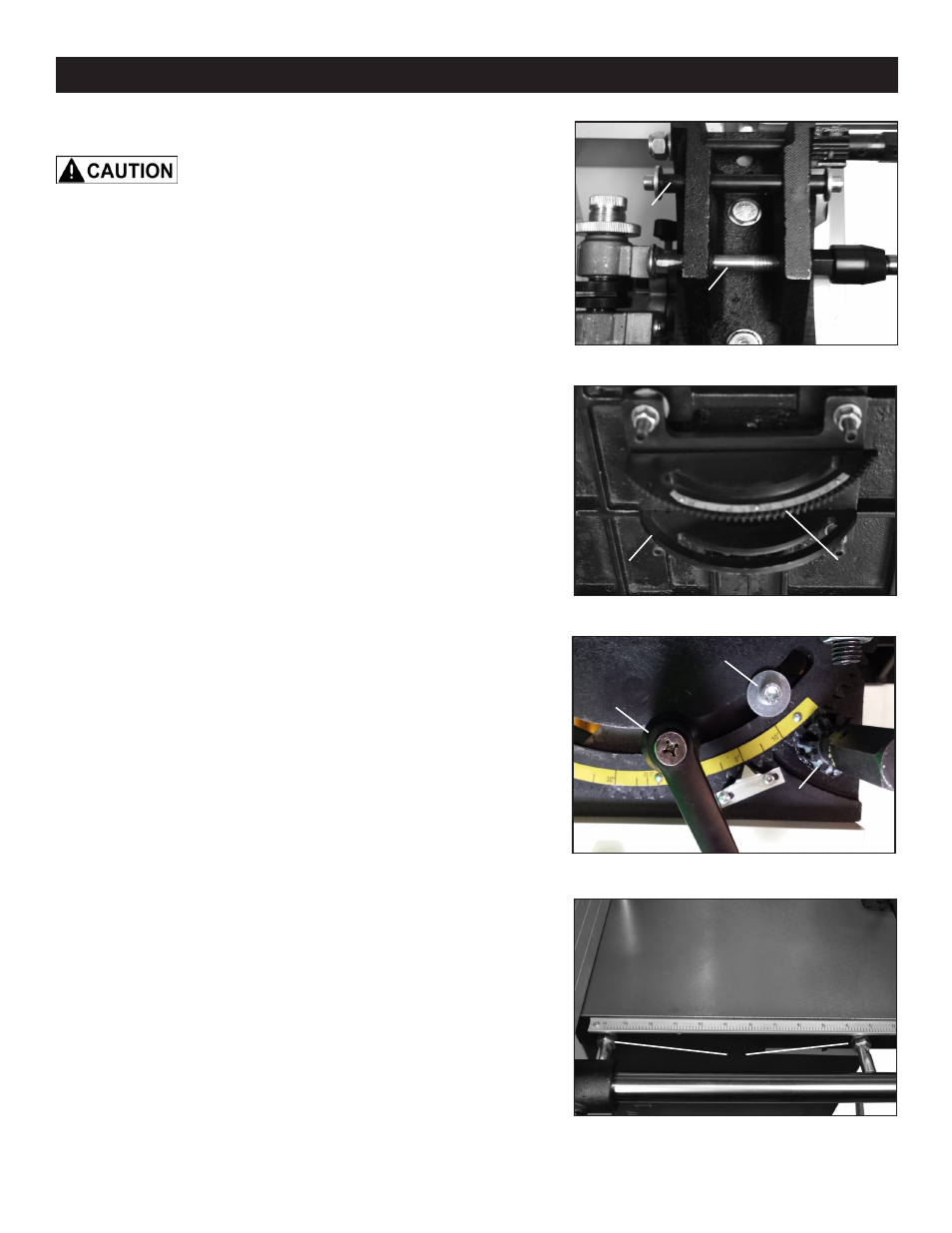

Figure 1

10

Figure 2

INSTALLING THE WORK TABLE

The Work Table is extremely heavy.

It may require two other individuals to assist with the

installation.

NOTE: The upper and lower bandwheel doors must

remain closed during table installation.

The guide shaft (A-Fig.1) and table locking hardware

(B-Fig.1) were installed on the lower trunnion (C-Fig.1)

during saw assembly. These need to be removed prior

to table installation.

NOTE: The bandsaw blade is installed at the factory. It

is recommended to remove the blade prior to installing

the table. See “CHANGING THE SAW BLADE” on page

13.

With the guide shaft, table locking hardware and blade

removed carefully lift the table (team lift) and lower the

upper trunnion (installed at factory) (A-Fig.2) onto the

lower trunnion. Ensure that the gear teeth on the upper

trunnion (B-Fig.2) engage the gear on the lower trunnion

(A-Fig.3).

Install the guide shaft and table locking hardware from

the left side of the upper trunnion (user cutting position)

through the lower trunnion and out the right side of the

upper trunnion.

NOTE: The table locking handle (B-Fig.3) is to be

installed on the right side of the upper trunnion in the

lower hole below the guide shaft position (C-Fig.3)

RIP FENCE RAIL

The Rip Fence Rail has been pre-assembled to the

work table for shipping. After mounting the work table

to the trunnions (see above instructions), the rail should

be checked to ensure that it is still properly tightened

in place to the table. If adjustments are needed, loosen

and/or re-tighten the four hex nuts on the fence bar

support shafts that extend through the table’s front skirt

edge (A-Fig.4).

The four nuts will also be used for drift adjustments,

described on page 15.

ASSEMBLY

Figure 3

B

A

B

A

A

B

C

C

Figure 4

A