Troubleshooting, Caution – Lincoln Electric IM680 Power Wave Water Cooler User Manual

Page 15

E-2

TROUBLESHOOTING

E-2

POWER WAVE WATER COOLER

If for any reason you do not understand the test procedures or are unable to perform the tests/repairs safely, contact your

Local Lincoln Authorized Field Service Facility

for technical troubleshooting assistance before you proceed.

CAUTION

Observe all Safety Guidelines detailed throughout this manual

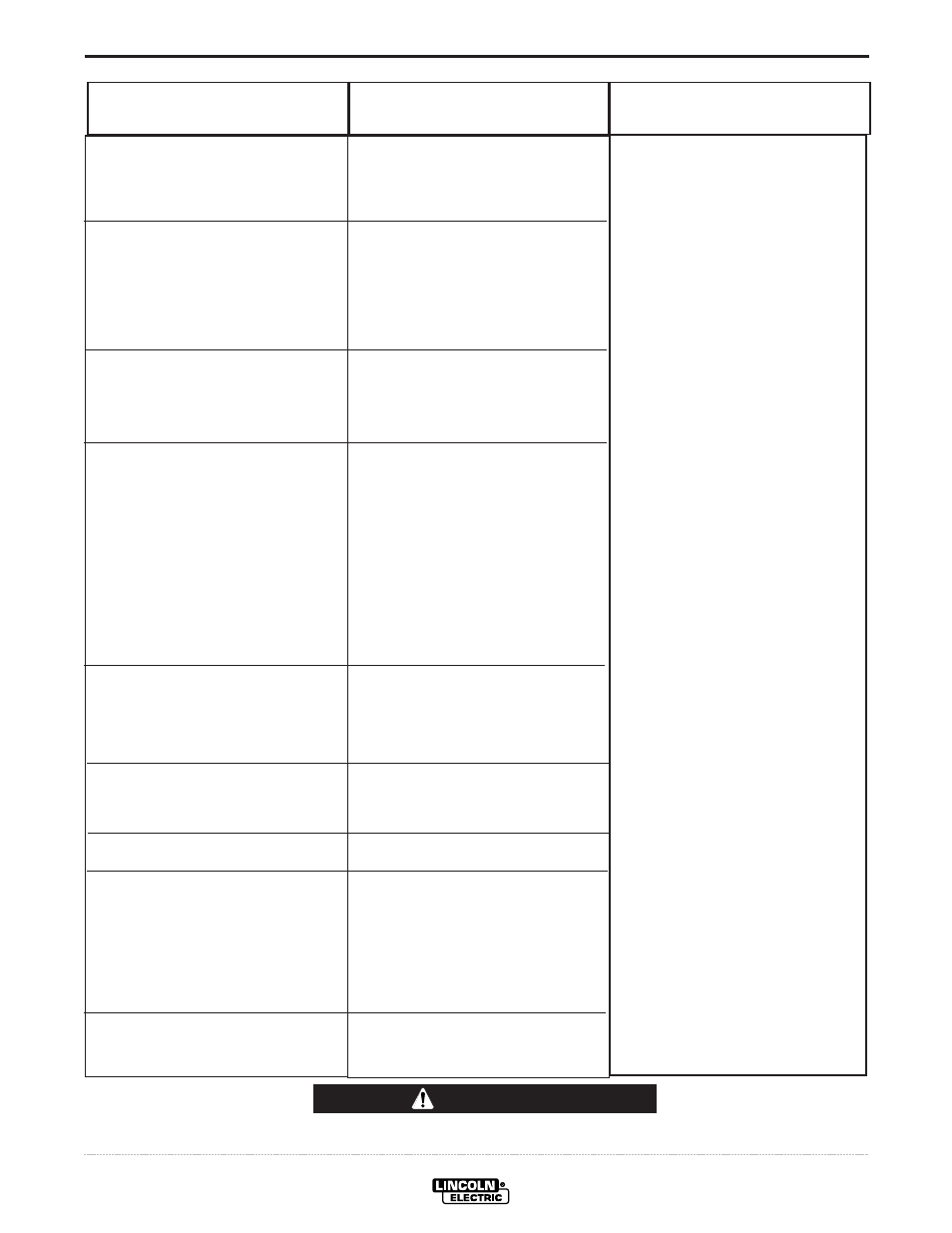

PROBLEMS

(SYMPTOMS)

POSSIBLE AREAS OF

MISADJUSTMENTS(S)

RECOMMENDED

COURSE OF ACTION

If all recommended possible areas

of misadjustment have been

checked and the problem persists,

Contact your local Lincoln

Authorized Field Service Facility.

Cooler does not operate with power

switch on.

(Switch pushed to

"1" position.) No

“

LED

”

Turn on.

Cooler does not operate with power

switch on, YELLOW LED

“

Flow

Fault

”

is on.

Internal water leak.

Torch or gun runs hot.

Fan operates but there is low

coolant flow. (Cooler will not contin-

uously operate)

Fan operates but there is no coolant

flow. (Cooler will not continuously

operate)

Cooler trips outlet circuit breaker.

The Cooler is on, but the Power

Wave still indicates that there is a

water fault.

1. Power cord unplugged to power-

wave not plugged in.

2. Power switch faulty.

3. Power harness damaged.

1. Water lines blocked or crimped.

2. Leak in gun or water hoses.

3. Reservoir empty.

4. Female quick-connect fittings are

not connected to male fittings.

5. The system needs to be primed.

1. Hose clamp loose on internal

hose.

2. Internal hose punctured.

3. Heat exchanger leaking.

1. Unit placed by area of extreme

heat.

2. Low coolant flow.

3. No coolant flow.

4. Fan not operating.

5. Heat exchanger clogged.(Air or

coolant side)

6. Torch or Gun exceeds cooler rat-

ing.

7. Welding output not disabled with

low or no coolant flow.

1. Leak in torch/gun or hoses.

2. Torch/gun or hoses partially

obstructed.

3. Pressure low (pump failing).

1. Pump motor failure.

2. Reservoir empty.

1. Circuit overloaded.

1. Verify that there is actually coolant

flow (ie no blocked connections,

proper coolant level)

2. Check that all connections in the

Power Wave

’

s green I/O connec-

tor are tight and that any insula-

tion is not pinched