Troubleshooting, Caution – Lincoln Electric IM666 TANDEM MIG Torch G3494-2A, 3A, 4A, 5A, 6A User Manual

Page 21

E-3

TROUBLESHOOTING

E-3

TANDEM MIG TORCH

Observe all Safety Guidelines detailed throughout this manual

If for any reason you do not understand the test procedures or are unable to perform the tests/repairs safely, contact your

Local Lincoln Authorized Field Service Facility for technical troubleshooting assistance before you proceed.

CAUTION

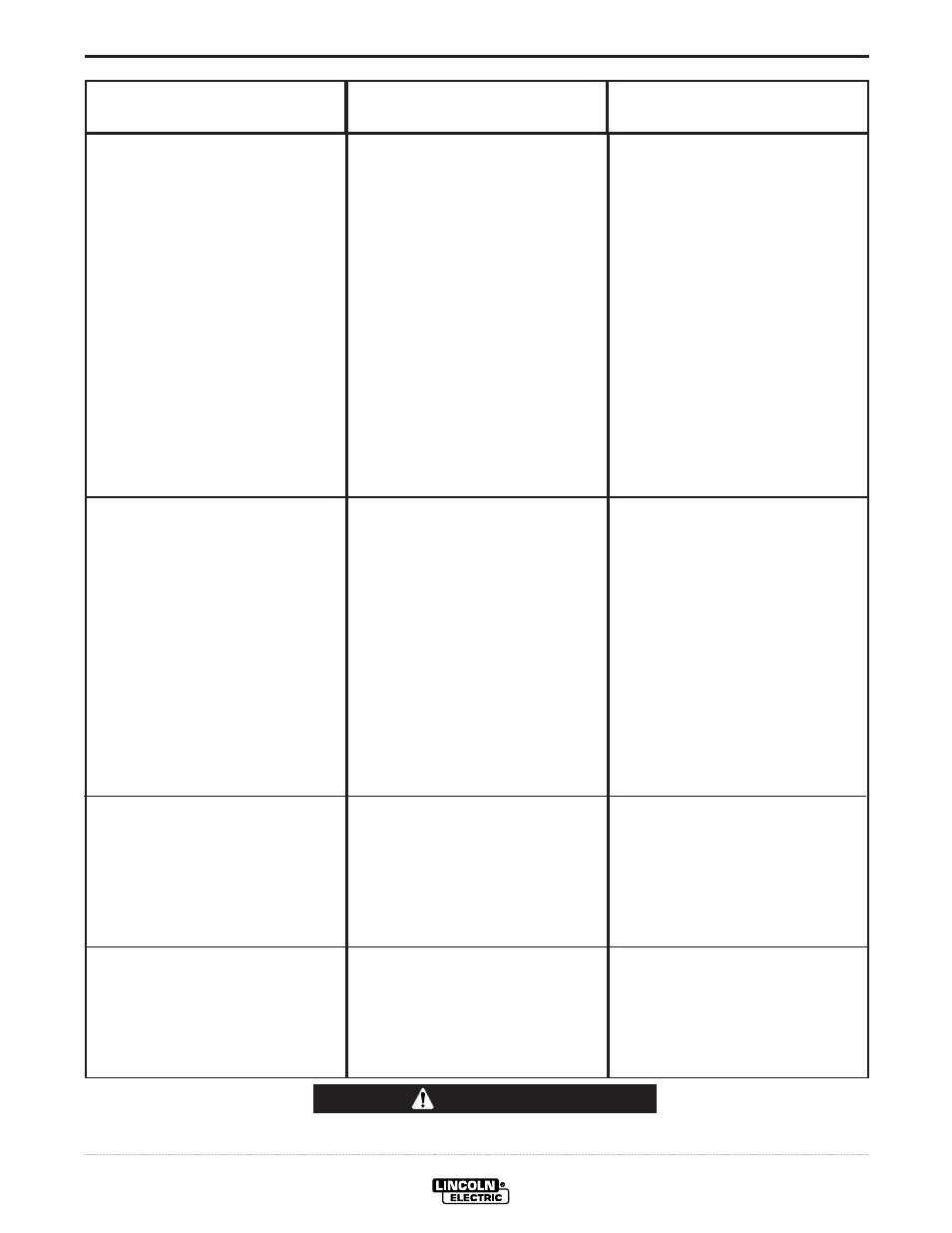

PROBLEMS

(SYMPTOMS)

PPOSSIBLE

CAUSE

RECOMMENDED

COURSE OF ACTION

Porosity in the weld. (Continued)

The arc length is inconsistent.

There is arcing to the nozzle.

There is arcing between the contact tips

or arc flaring.

g. Wrong shielding gas composition.

h. Lead arc length too short.

i. Water is leaking into the arc.

j. Air is being drafted through the barrel.

k. Weld is too large.

l. Excessive anti-spatter fluid.

m. For installations with an anti-spatter

system, the anti-spatter solenoid may

not be closing completely.

n. For installations without an anti-spat-

ter system, the line may not be

plugged.

a. The contact tip is worn.

b. The liner and/or conduit are dirty or

worn.

c. The drive rolls and guide tubes on the

wire feeder are not properly assem-

bled.

d. The variation in the joint is too large.

e. The electrode or work lead connec-

tions are loose.

f. Only one ground lead is being used.

g. The wrong weld program has been

selected.

a. Spatter build-up is bridging between

the nozzle and contact tips or diffusers

b. The nozzle is too narrow for the appli-

cation.

c. The torch is not insulated from the fix-

ture.

a. Spatter build-up is creating a bridge

between the contact tips.

b. The wire size selection is wrong.

g. Make sure the shielding gas is appro-

priate for the weld procedure.

h. The lead arc should be in the spray or

pulse mode and not in globular or

short arc transfer.

i. Verify that nozzle to torch o-rings are

sealing properly.

j. Check that the o-rings to seal the bar-

rel to the over molded assembly are

sealing properly.

k. Use a trailing gas shield or a nozzle

that supplies a wider coverage of gas

shielding.

l. Use only a minimal amount of anti-

spatter fluid.

m. Verify that the solenoid closes com-

pletely.

n. Make sure the anti-spatter line is

plugged and sealed.

a. The wire should slide freely through

the contact tip. Replace if necessary.

b. Clean the liners and conduit. Replace

if necessary.

c. Make sure the correct size drive rolls

and guide tubes are in the feeder the

wire feeds through without distortion.

d. Improve fixturing and part forming if

necessary, or add seam tracking.

e. Verify that all the connections are tight

and are not overheating.

f. Use an individual ground lead from the

work stud of each power source to the

fixture.

g. Make sure the welding program on the

power source matches the wire size

and gas actually being run.

a. Remove spatter build-up on a regular

basis. Adjust weld procedure to

reduce spatter.

b. Switch to a wider nozzle.

c. Make sure the torch is on an insulated

mount. Use M19190 insulator if neces-

sary.

a. Remove spatter build-up on a regular

basis. Adjust procedure to reduce

spatter.

b. Switch to a larger diameter lead and

trail wire.