Operation, Caution – Lincoln Electric IM727 SAE400 SEVERE DUTY User Manual

Page 16

B-4

OPERATION

B-4

WELDER CONTROLS

POLARITY SWITCH

Turn the Arc Polarity switch to electrode positive or

electrode negative as required for each particular

application.

CONTROL OF WELDING CURRENT

Purpose of Controls

The continuous

“

Current Control

”

is the main current

adjuster. The

“

Job Selector

”

is both a fine current

adjuster and the continuous Open Circuit Voltage

adjuster. Open Circuit Voltage (OCV) controls the arc

characteristics.

“Job Selector”

The

“

Job Selector

”

dial is divided into four colored sec-

tions providing OCV ranges as follows:

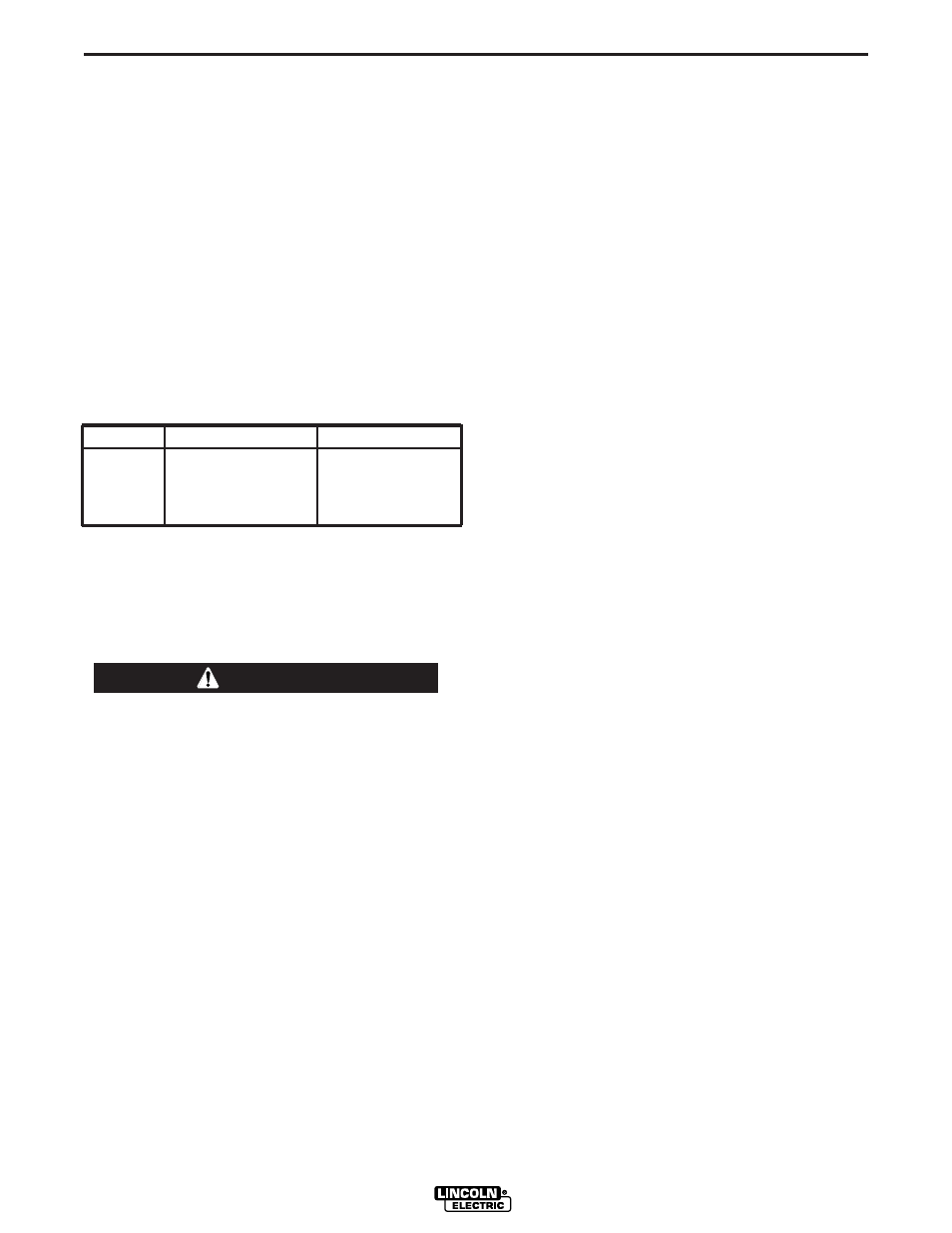

Color

Title

OCV Range

White

Large Electrodes

High OCV

Black

Normal Welding

Medium OCV

Red

Overhead & Vertical

Low OCV

Grey

Special Applications

Extra-Low OCV

The

“

Job Selector

”

is usually set in the black range

because it provides a soft

“

Buttering

“

arc desired for

most welding. Some operators prefer to set the

“

Job

Selector

”

in the red range for a snappy

“

Digging

”

arc

when welding vertical up or overhead.

“Current Control”

Do not adjust the

“

Current Control

”

while welding

because this can damage the control.

------------------------------------------------------------------------

The

“

Current Control

”

dial is calibrated in amperes on

three separate colored dials corresponding to the

white, black and red ranges of the

“

Job Selector

”

dial.

For example: when the

“

Job Selector

”

is set on the

black range, the approximate welding current is indi-

cated on the black scale of the

“

Current Control

”

dial.

How to Set the Controls

Assume you want a normal soft arc and about 135

amps, using a 5/32

”

(4.0 mm) electrode:

1. Set the

“

Job Selector

”

at the center of the black

range.

2. Set the

“

Current Control

”

to read 135 amps on the

black dial.

3. Start to weld.

4.

If you want a little more current, turn the

“

Job

Selector

”

up (counterclockwise) to increase cur-

rent. If you want a little less current, turn the

“

Job

Selector

”

down (clockwise) to decrease current.

5. If dialing the desired current with the

“

Job

Selector

”

moves the setting outside the black

range causing undesirable arc characteristics, turn

the

“

Job Selector

”

back to the center of the black

range. Then turn the

“

Current Control

”

up or down

a little as needed. Readjust the

“

Job Selector

”

for

the exact characteristics and current desired.

REMOTE CONTROL

A receptacle and

“

Local/Remote

”

control switch on the

lower front control panel and a remote control box with

100 ft. (30.5 m) of cord for adjusting the OCV at the

welding site are standard. Putting the switch in the

“

REMOTE

”

position allows fine current control at the

remote control box while placing the switch in the

“

LOCAL

”

position allows fine current control at the

“

Job

Selector

”

on the machine.

AUXILIARY POWER CONTROLS

Note: GFCI receptacles our an option and if installed,

see the

“

MAINTENANCE SECTION

”

for detailed

information on testing and resetting the GFCI

receptacle.

115 VAC Receptacle

One 20 amp, 115 VAC duplex receptacle provides 115

VAC for auxiliary power. A total of 26 amps can be

drawn from this receptacle.

230 VAC Receptacle

One 15 amp, 230 VAC duplex receptacle provides 230

VAC for auxiliary power. A total of 13 amps can be

drawn from this receptacle.

Circuit Breakers

The circuit breakers provide separate overload current

protection for each half of the 115 V duplex receptacle.

The circuit breakers provide overload current protec-

tion in both current carrying wires of the 230 V duplex

receptacle.

Ground Stud

Provides a connection point for connecting the

machine to earth ground. For the safest grounding pro-

cedure refer to

“

Machine Grounding

”

in the INSTALLA-

TION section of this manual.

SAE-400 SEVERE DUTY

CAUTION