Lincoln Electric IM672 RED-D-ARC ZR-8 User Manual

Page 20

– 19 –

Wire Feed Welding Processes

(Constant Voltage)

The only Innershield

®

electrode recommended for use

with the ZR-8 is NR

®

-211-MP. The electrode sizes

and welding ranges that can be used with the ZR-8

are shown in the following table:

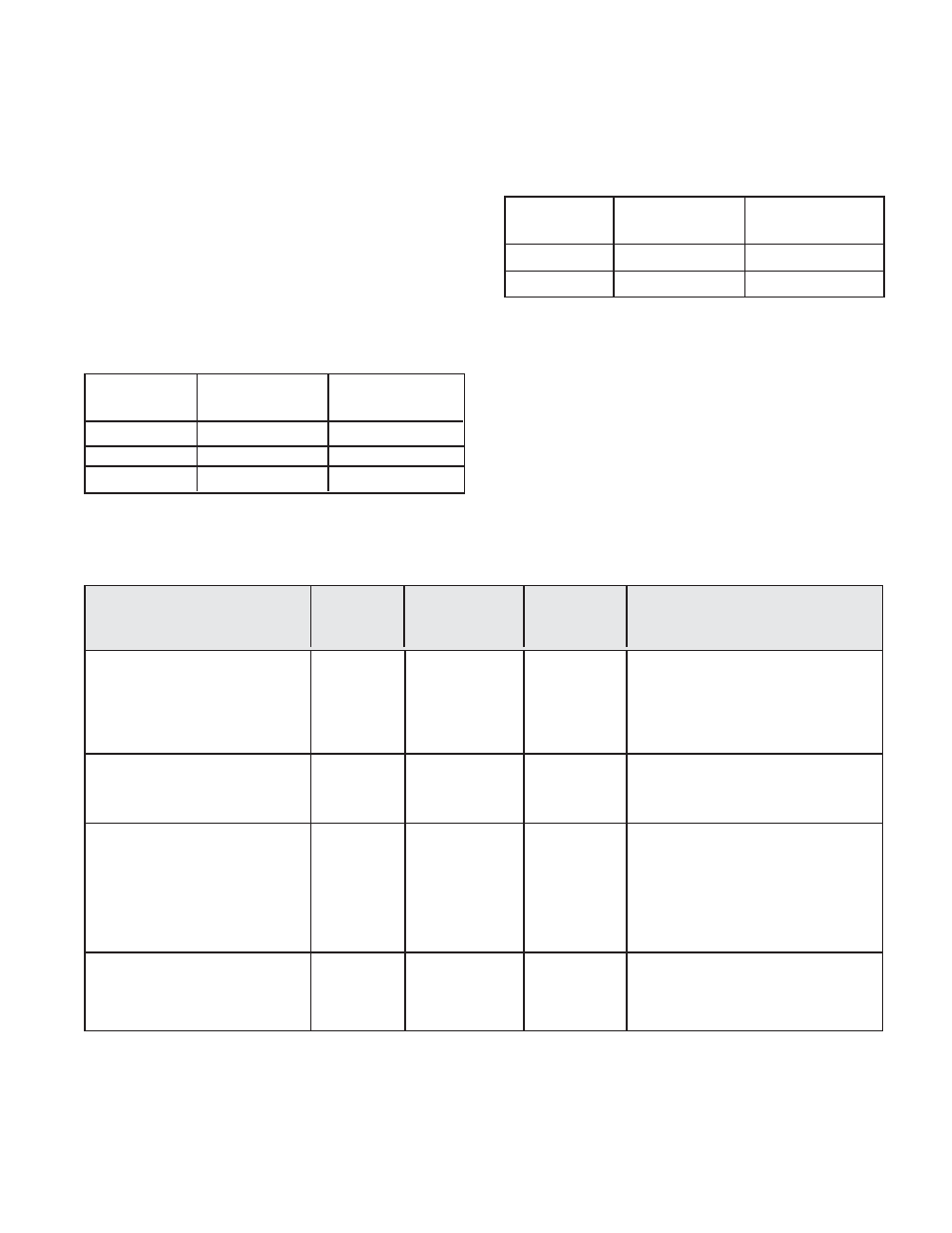

Diameter Wire Speed Approximate

(in.) Range In./Min. Current Range

.035

80 - 110

75A to 120A

.045

70 - 130

120A to 170A

.068

40 - 90

125A to 210A

The ZR-8 is recommended for limited “MIG” welding

(GMAW - gas metal arc welding). The recommended

electrodes are .030” and .035” L-50 and L-56. They

must be used with a blended shielding gas such as

C25 (75% Argon - 25% CO

2

). The welding ranges

that can be used with the ZR-8 are shown in the fol-

lowing table:

Diameter Wire Speed Approximate

(in.) Range In./Min. Current Range

.030

80 - 110

75A to 120A

.035

70 - 130

120A to 170A

Summary of Welding Processes

CONTROL ELECTRODE

CABLE IDLE WHEN NOT TO START

PROCESS USED MODE WELDING WELDING

STICK

No

AUTO

Hot

Touch electrode to work.

Welding starts immediately

and engine goes to high

idle.

TIG/K7930-1/K938-1,

Yes

HIGH

Cold

Press Amptrol, contactor

K936-( ) /K892-1

closes, welding

(WITH AMPTROL)

starts immediately.

WIRE FEED, LN-25 WITH

No

AUTO

Cold

Press gun trigger, LN-25

INTERNAL CONTACTOR

contactor closes. Welding

starts immediately and

engine goes to high idle.

NOTE: Output Control

must be set above “3”.

WIRE FEED, LN-7 WITH

Yes

HIGH

Cold

Press gun trigger,

K240 CONTACTOR KIT

contactor closes. Welding

starts immediately.

The K930-1 TIG Module should be used with the ZR-

8 on high idle to maintain satisfactory operation. It can

be used in the AUTO position but the delay going to

flow idle after welding is ceased will be increased if

the AFTERFLOW CONTROL is set above 10 sec-

onds