Operation, B-3 welding process – Lincoln Electric IM831 RANGER 3 PHASE User Manual

Page 19

B-3

OPERATION

B-3

WELDING PROCESS

For any electrodes the procedures should be kept

within the rating of the machine. For electrode infor-

mation see the appropriate Lincoln publication.

STICK (CONSTANT CURRENT) WELDING

Connect welding cables to the "TO WORK

”

and

"ELECTRODE

”

studs. Start the engine. Set the

"Polarity

”

switch to the desired polarity. The

“

RANGE

”

switch markings indicate the maximum current for that

range as well as the typical electrode size for that

range. The

“

OUTPUT

”

Control provides fine adjust-

ment of the welding current within the select range.

For maximum output within a selected range set the

“

OUTPUT

”

Control at 10. For minimum output within a

selected range set the

“

OUTPUT

”

Control at 5. (

“

OUT-

PUT

”

Control settings below 5 may reduce arc stabili-

ty) For best overall welding performance set the

“

RANGE

”

Switch to the lowest setting and the OUT-

PUT

”

Control near the maximum to achieve the

desired welding current.

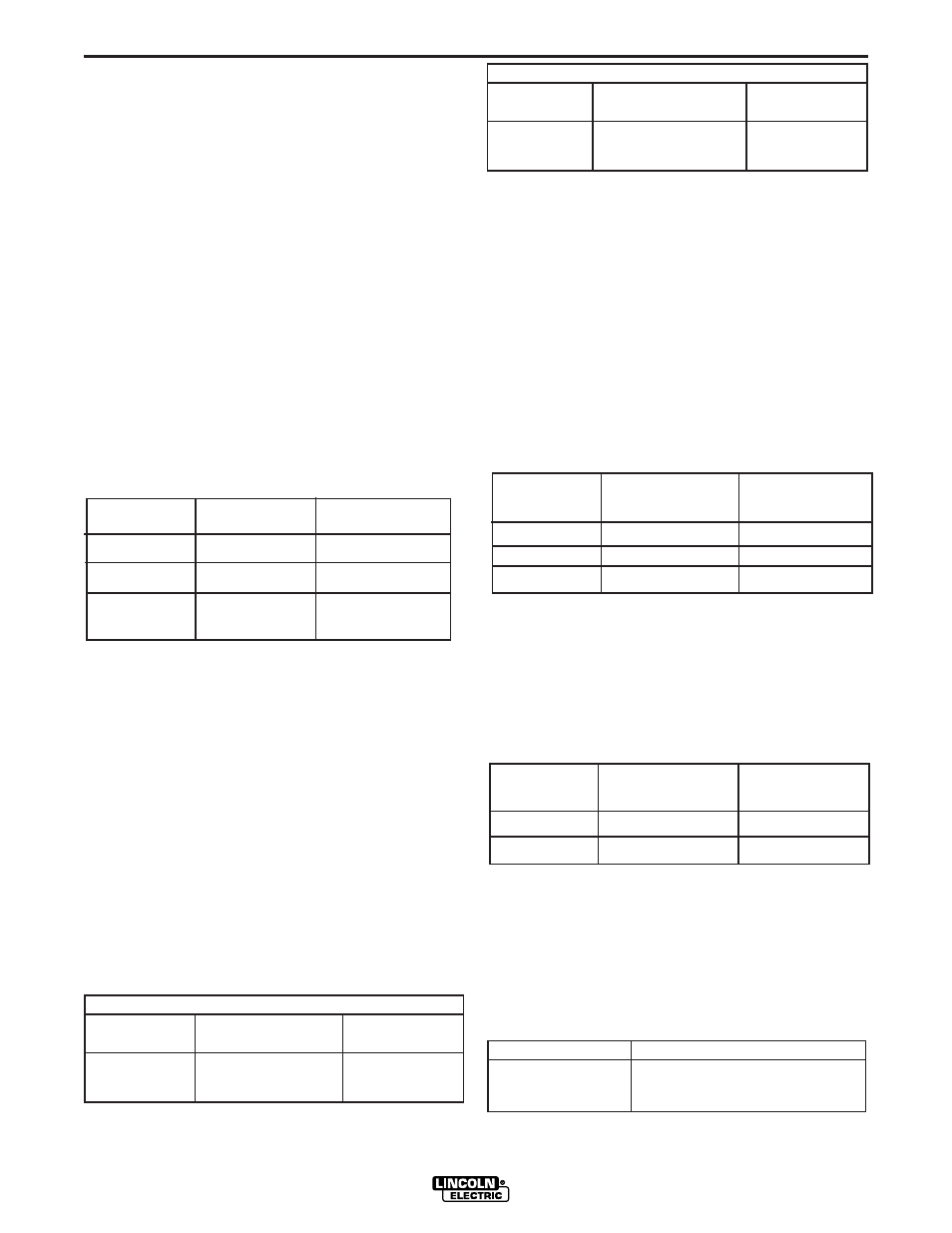

RANGE SETTING

TYPICAL

CURRENT RANGE

ELECTRODE SIZE

The RANGER 3 PHASE can be used with a broad

range of AC and DC stick electrodes. See

“

Welding

Tips 1

”

included with the RANGER 3 PHASE for elec-

trodes within the rating of this unit and recommended

welding currents of each.

TIG (CONSTANT CURRENT) WELDING

The K930-[ ] TIG Module installed on a RANGER 3

PHASE provides high frequency and shielding gas

control for AC and DC GTAW (TIG) welding process-

es. The TIG Module allows full range output control.

After flow time is adjustable from 0 to 55 seconds.

When using the RANGER 3 PHASE for AC TIG weld-

ing of aluminum, the following settings and electrodes

are recommended:

The K930-[ ] TIG Module should be used with the

RANGER 3 PHASE on high idle to maintain satisfac-

tory operation. It can be used in the AUTO position

but the delay going to flow idle after welding is ceased

will be increased if the AFTER FLOW CONTROL is

set above 10 seconds.

WIRE FEED WELDING PROCESSES

(CONSTANT VOLTAGE)

The Innershield

®

electrode recommended for use with

the RANGER 3 PHASE is NR

®

-212-MP. The elec-

trode sizes and welding ranges that can be used with

the RANGER 3 PHASE are shown in the following

table:

The RANGER 3 PHASE is recommended for limited

“

MIG

”

welding (GMAW - gas metal arc welding). The

recommended electrodes are.030

”

and .035

”

SuperArc

L-50 and L-56. They must be used with a blended

shielding gas such as C25 (75% Argon - 25% CO

2

).

The welding ranges that can be used with the

RANGER 3 PHASE are shown in the following table:

ARC GOUGING

The RANGER 3 PHASE can be used for limited arc

gouging.

Set the Range switch to adjust output current to the

desired level for the gouging electrode being used

according to the ratings in the following table:

RANGER 3 PHASE

Diameter Wire Speed Approximate

(in.) Range In./Min. Current Range

.035

80 - 110

75A to 120A

.045

70 - 130

120A to 170A

.068

40 - 90

125A to 210A

Diameter Wire Speed Approximate

(in.) Range In./Min. Current Range

.030

80 - 110

75A to 120A

.035

70 - 130

120A to 170A

SETTINGS FOR PURE TUNGSTEN

TUNGSTEN RANGE SWITCH

APPROXIMATE

DIAMETER (in.) SETTINGS CURRENT RANGE

1/8 90 or 145 80 - 150 Amps

3/32 90 or 145 45 - 130 Amps

1/16 90

40 - 80 Amps

SETTINGS FOR 1% THORIATED TUNGSTEN

TUNGSTEN RANGE SWITCH

APPROXIMATE

DIAMETER (in.) SETTINGS CURRENT RANGE

1/8 90, 145, or 210 80 - 225 Amps

3/32 90 or 145 50 - 180 Amps

1/16 90 or 145 45 - 120 Amps

CARBON DIAMETER (in) CURRENT RANGE (DC, electrode positive)

1/8 30 - 60 Amps

5/32 90 - 150 Amps

3/16 150 - 250 Amps

90 MAX.

125 MAX.

210(DC)/225(AC)

MAX.

3/32

1/8

5/32

50 TO 90 AMPS

70 TO 145 AMPS

120 TO 210(DC),

225(AC) AMPS