Lincoln Electric IM773 Push-Pull Gun PYTHON K2211-2, K2211-3, K2212-1, K2212-2 & K2212-3 User Manual

Page 12

Python Owner's Manual - Page 2

Gas Hose

The gas hose is secured over the barbed gas fitting with a tie wrap. The

cabinet end of the gas hose uses our standard gas fitting (1/8” - 27 nps).

Water Hose

If so equipped, one end of the water hose is secured over the barbed water

fitting with a tie wrap and the other end is connected to the center fitting on

the power block.

Electric Cable

A seven conductor control cable is used on the Python

®

gun. The gun end of

the control cable is secured to the gun with a boot clamp and soldered into

the pot assembly and micro switch connectors. Slack is left in the electric

cable as it exits the back of the gun to prevent cable breakage. The cabinet

end has a seven pin “W” clocked amphenol connector.

Section B

Operation

General

The Python

®

gun maintains a constant, steady, uniform wire feed speed,

regardless of curved or looped wire conduit. The constant push exerted

by the slave motor in the cabinet, combined with the pull of the gun motor,

causes the wire to literally float friction-free through the wire conduit. The

24VDC gun motor is controlled by a three and three-quarter (3 3/4) turn

potentiometer in the gun handle.

Controls and Settings

Potentiometer

The laterally-positioned potentiometer is located in the lower end of the

handle, providing up to 800 IPM with 3 3/4 turns.

Micro Switch

The micro switch assembly consists of the micro switch, and leads.

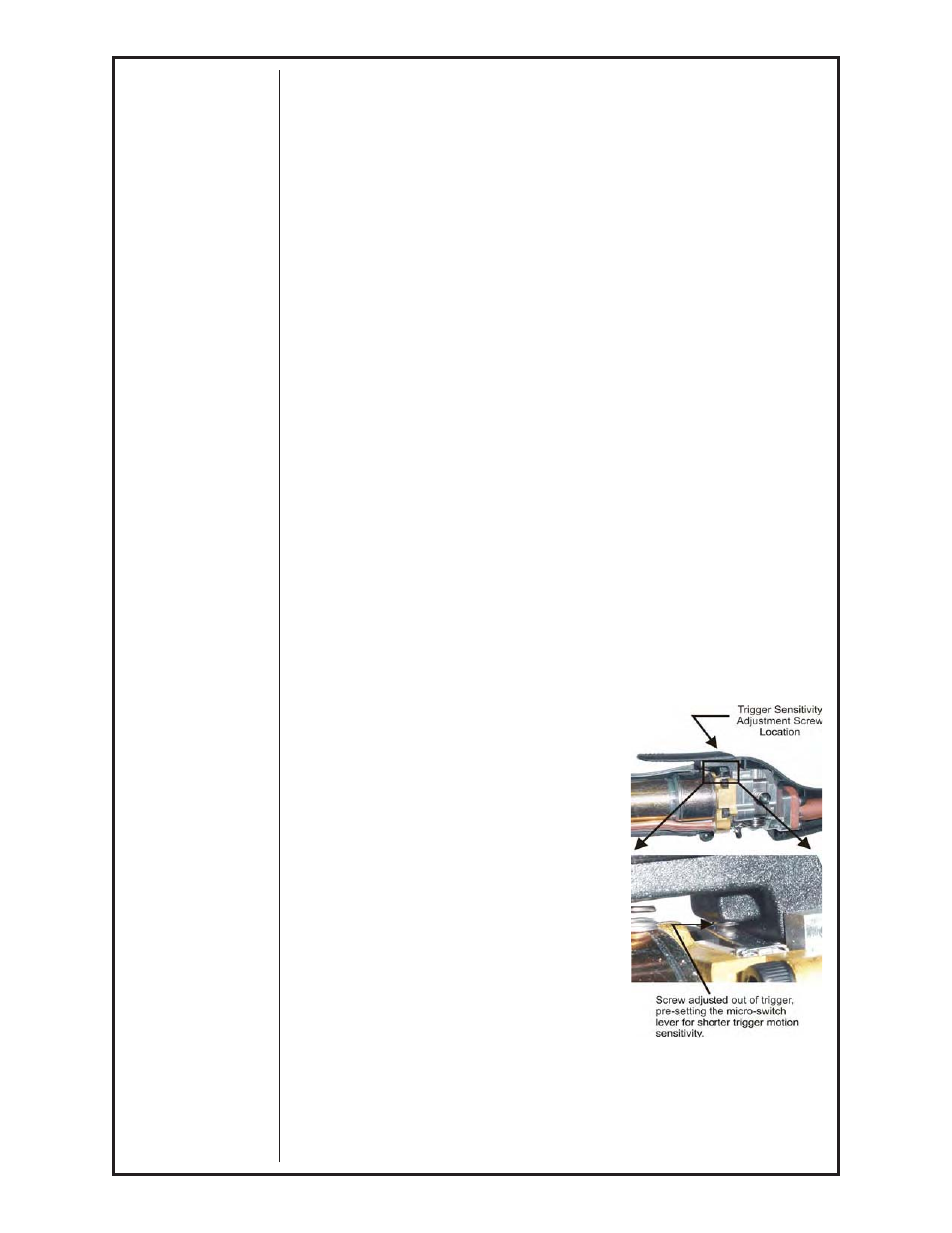

Trigger Sensitivity

The amount of trigger level travel can be

shortened for a "quicker" or "more responsive"

action.

A more sensitive trigger lever is produced by

reducing the gap between the trigger lever and

the micro-switch lever. By turning-in the Trigger

Sensitivity Adjustment Screw, it closed the gap

between the trigger lever and the micro-switch

lever.

This will enable the operator to increase the

sensitivity of the trigger lever.

Sensitivity Adjustment

With the wire feeder turned on (with or without

welding wire loaded), turn the screw in until

the micro-switch is activated. Once activated,

the tortch and wire feeder motors will begin

feeding wire. Retract the screw accordingly until

the system is deactivated and adjusted to the

operators' liking.