Troubleshooting, Caution – Lincoln Electric IM718 POWER WAVE AC_DC User Manual

Page 35

E-5

TROUBLESHOOTING

E-5

POWER WAVE AC/DC

Observe all Safety Guidelines detailed throughout this manual

If for any reason you do not understand the test procedures or are unable to perform the tests/repairs safely, contact your

Local Lincoln Authorized Field Service Facility for technical troubleshooting assistance before you proceed.

CAUTION

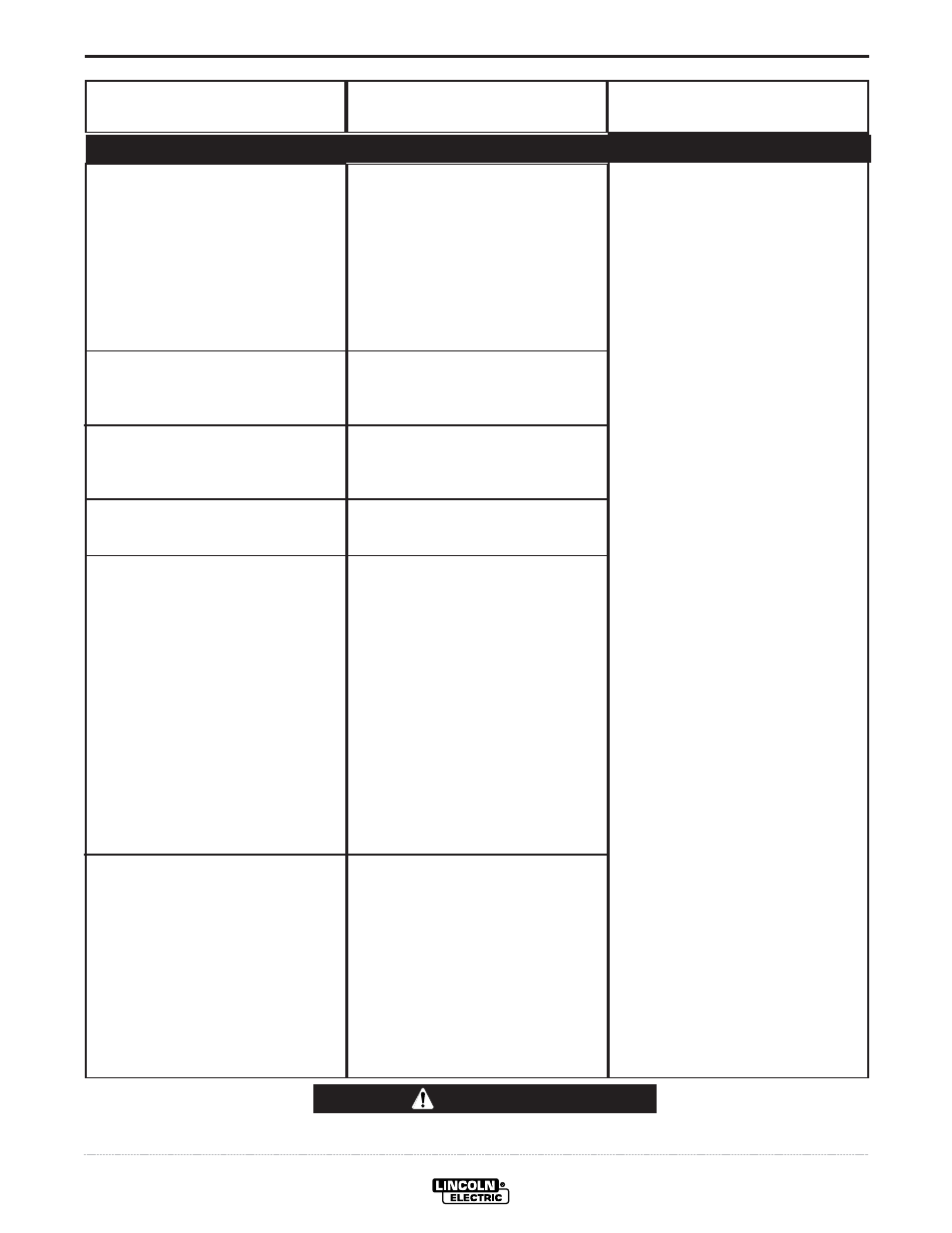

PROBLEMS

(SYMPTOMS)

POSSIBLE AREAS OF

MISADJUSTMENTS(S)

RECOMMENDED

COURSE OF ACTION

General degradation of the weld

performance.

The Power Wave is triggered to

weld, but there is no output.

The feeder will not cold inch wire

Excessively long and erratic arc.

Arc loss fault on robot

1. Check for feeding problems, bad

connections, excessive loops in

cabling, etc..

2. Verify weld mode is correct for

processes.

3. The power source may require

calibration.

•

Check the current calibration

•

Check the voltage calibration

•

Check the WFS calibration

1. Check for fault signals from the

I/O connector. Possible faults are

lack of water flow / water flow

turned off.

1. Check for fault signals from the

I/O connector. Possible faults are

lack of water flow / water cooler

turned off.

1. Check for proper configuration

and implementation of voltage

sensing circuits.

1. Possibly caused by wire feeding

problem.

2. Possible causes/solutions are:

•

Problem - Conduit leading to the

wire feeder has bends or twists,

which can reduce the wire feed

speed.

•

Solution - Remove bends and

twists from conduit.

•

Problem

–

Conduit leading up to

the wire feeder from the wire reel

is too long.

•

Solution

–

Use a shorter length of

conduit

If all recommended possible areas of

misadjustments have been checked

and the problem persists, contact

your local Lincoln Authorized

Field Service Facility.

OUTPUT PROBLEMS