Maintenance, Caution – Lincoln Electric IM560 POWER-ARC 5000 User Manual

Page 38

D-2

MAINTENANCE

D-2

CLEAN AIR FILTER PRE-CLEANER

Do not use petroleum solvents such as kerosene to

clean the air pre-cleaner. They may cause deteriora-

tion of the air pre-cleaner. DO NOT USE PRESSUR-

IZED AIR TO CLEAN OR DRY THE AIR PRE-CLEANER.

To service the pre-cleaner:

1. Wash in liquid detergent and water.

2. Squeeze dry in a clean cloth.

3. Saturate in clean engine oil.

4. Squeeze in a clean, absorbent cloth to remove all

excess oil.

CLEAN ENGINE: Remove dirt and debris with a cloth

or a brush. Do not clean with a forceful spray of

water. Water might contaminate the fuel system.

Periodically clean the muffler area to remove com-

bustible debris.

Clean Rotating Screen: See Figure D.2. Clean the

rotating screen on your machine’s engine as often as

needed to remove dirt or debris that may collect on

the screen. A dirty screen can result in engine over-

heating and damage.

FIGURE D.2 - CLEAN ROTATING

SCREEN/FINGER GUARD/DEBRIS GUARD

1. ROTATING SCREEN

CLEAN COOLING SYSTEM: See Figure D.3. Clean

the internal cooling fins and surfaces to prevent over-

speeding, overheating, and engine damage. Clean

every 100 operating hours or as often as necessary

using a brush and low pressure air.

FIGURE D.3 - CLEAN COOLING SYSTEM

1. REMOVE DIRT FROM THESE AREAS.

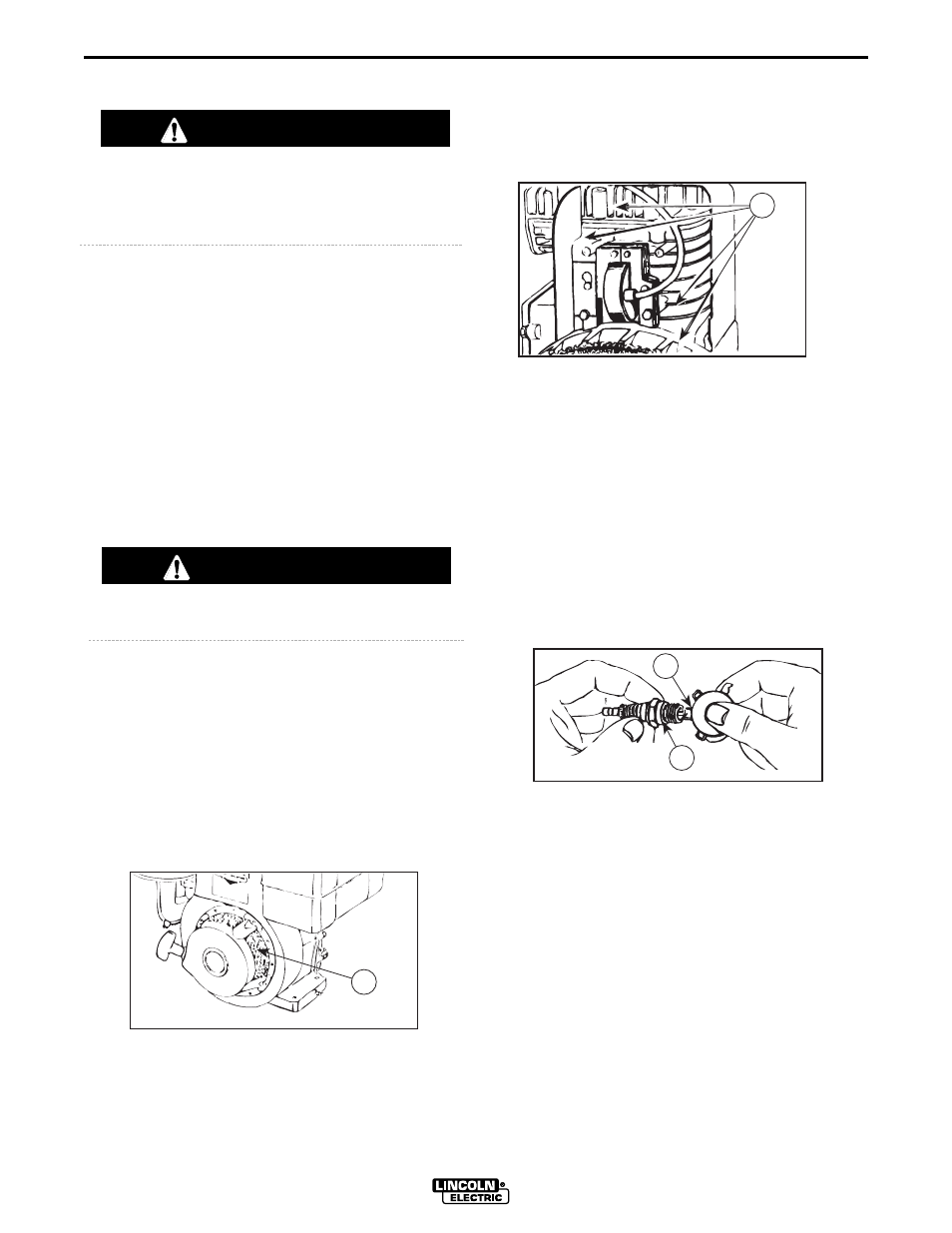

CLEAN OR REPLACE SPARK PLUG: Clean or

replace the spark plug after every 100 hours of opera-

tion or every season, whichever comes first. Do not

blast the spark plug clean with an abrasive cleaning

device. Clean the plug by scraping it or by using a

wire brush. Wash the plug with a commercial sol-

vent. After cleaning or when installing a new spark

plug, set the terminal gap to .030 inch (.76 mm) with a

feeler gauge. See Figure D.4.

FIGURE D.4 - SET SPARK PLUG GAP

Use the Briggs & Stratton Engine Manual for latest Plug Gap Info.

CLEAN SPARK ARRESTER SCREEN: If the muffler

has the optional spark arrester assembly, remove it

every 50 hours or once a year, whichever comes first,

and inspect it. Clean the arrester. Replace it if you

find any damage.

CYLINDER HEAD TORQUE PROCEDURE: Use a

torque wrench and tighten the cylinder head bolts to

165 inch pounds in the sequence shown in Figure

D.5. This procedure is to be performed after the first

100-300 hours of operation.

POWER ARC 5000

CAUTION

CAUTION

1

1

2

1