Installation, Mounting the lta 2.0 telescopic arm, Adjusting the friction of the telescopic arm – Lincoln Electric IM624 LTA 2.0 TELESCOPIC EXTRACTION ARM User Manual

Page 10

A-3

INSTALLATION

LTA 2.0 TELESCOPIC EXTRACTION ARM

A-3

MOUNTING THE LTA 2.0

TELESCOPIC ARM

(continued)

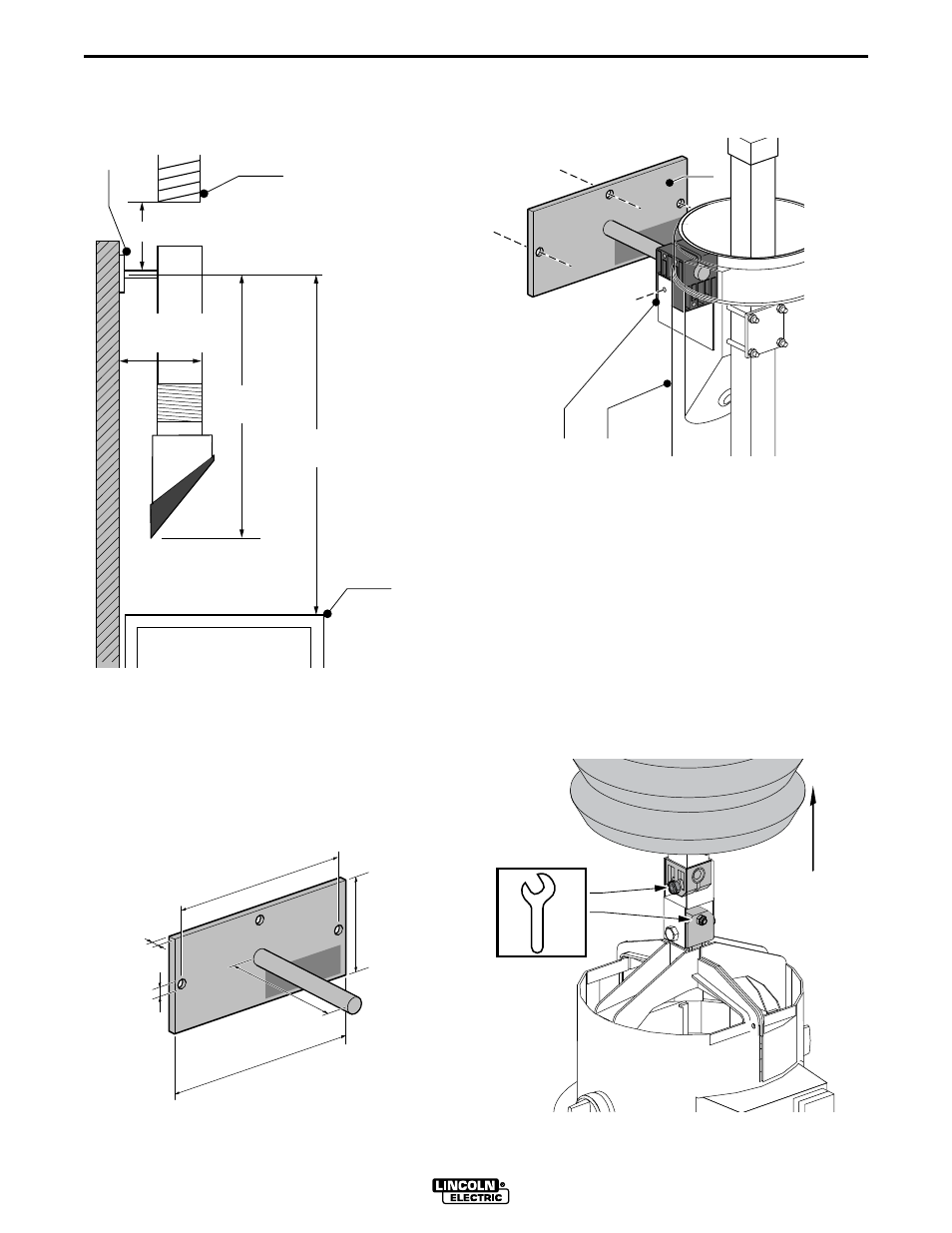

Disconnect the mounting bracket from the arm before

mounting, by removing the 1.75” bolt (Fig. 3C), and

sliding the post out of the friction block. Mount the

telescopic arm mounting bracket to the wall. Standard

mounting height is 5 ft. (130 mm) from the work table

to the center of the bracket. Refer to Figure 2 for

drilling dimensions.

Remount the arm to the mounting bracket by sliding

the friction block over the post of the bracket (Fig. 3A)

and replacing the 1.75” bolt and nut (Fig. 3C).

ADJUSTING THE FRICTION OF THE

TELESCOPIC ARM

The amount of friction resistance should be set such

that the arm is comfortable to move (always test both

up and down movements), yet hold its position against

gravity once positioned.

To adjust the friction resistance of the hood move-

ment, fold back the rubber band onto the hood, and

push up the flexible hose, exposing the connection

blocks. Use an 8mm wrench to adjust the bolt/nut

pairs as shown in Fig. 4.

11.8"

(300 mm)

38.6-54.3"

(980-1380 mm)

B

C

A

11.8-15.7"

(300-400 mm)

63"

(1600 mm)

4.7"

(120 mm)

10"

(255 mm)

9"

(230 mm)

0.4"

(10 mm)

8.3"

(210 mm)

ш0.5"

(ш13 mm)

Fig. 2

B

B

B

Fig. 4

Fig. 1

C

B

A

Fig. 3