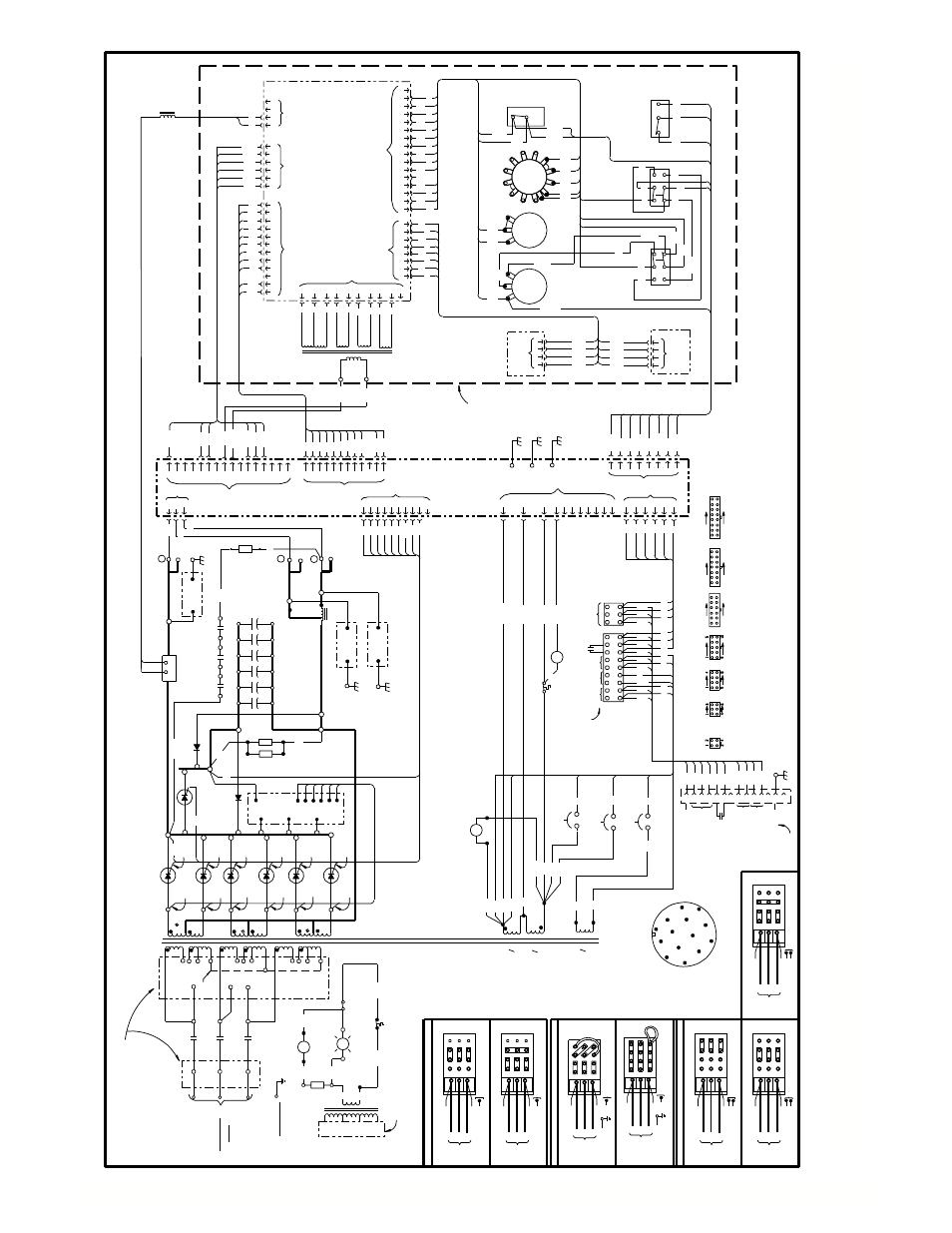

Dc-650 pro wiring diagram – Lincoln Electric IM463 IDEALARC DC-650 Pro User Manual

Page 27

–

27

–

PL1

10/50W

50/100W

10K/2W

10K/2W

S

S

4-29-94C

G

REMOTE

CONTROL

RESISTORS = OHMS/WATT UNLESS OTHERWISE SPECIFIED

ALL SWITCH WIRING VIEWED FROM REAR OF SWITCH

(SEE DETAILS)

RECONNECT PANEL

T1

T2

T3

TO SUPPLY

LINES

(SEE DETAILS)

RECONNECT PANEL

GMAW, FCAW

SMAW, SAW

216

209A

200A

324

320

319

318

317

361

362

363

366

364

TERMINAL STRIPS)

(FRONT VIEW OF

TS1

TS2

REMOTE

CONTROL

CUSTOMER

CONNECTIONS

WIRE FEEDER

S6

PROTECTION

P. C. BOARD

++++++

CR2

CR2

CR2

208

G1

G2

G3

G4

G5

G6

211

230

CR2

230A

214

330

332A

T3

18VAC

321

375A

304A

302A

340

342

341

343

344

345

346

347

R2

R1

J12

J13

307A

309A

308

332

329

314

307A

309A

308

332

329

314

317

377

323

322

376

S4

323A

323A

375

302

304

377

375A

302A

321

304A

376

307

G7

29

SCR1

200

D1

D2

211B

221

R4

R5

31,000 uF/50V EACH

75

77

21

2

76

4

77

76

75

21

4

2

H

E

G

F

A

J

C

D

N

K

B

L

M

I

42VAC

115VAC

77A

76A

75A

41A

42A

77

76

75

21

4

2

A

A

A

A

A

A

31

32

31

32

33

A

A

41

42

32

41

42

C

A

A

CONTROL BOX

203

205

SUPPRESSOR

BOARD

SUPPRESSOR

BOARD

B

B

O

O

(A1)

(A2)

(A3)

(A4)

(A5)

(A6)

G7

(A1)

(A2)

(A3)

(A4)

(A5)

(A6)

204

TOROID

CONTROL

P. C. BOARD

B

W

344

345

346

347

340

342

341

343

CONNECTOR CAVITY NUMBERING SEQUENCE

(COMPONENT SIDE OF P. C. BOARD)

+

-

THERMOSTAT

1

4

7

10

2

5

8

11

3

6

9

12

4 PIN

8 PIN

2

42V

10 PIN

O3

3

1

1

2

3

4

SHUNT

GENERAL INFORMATION

ELECTRICAL SYMBOLS PER E1537

INDUCTOR

OUTPUT

TO GROUND

L2

L1

L3

A

B

C

800 A. 50mV

O1

O2

115V

10VAC

24VAC

1

2

3

4

OUTPUT

CONTROL

ARC

FORCE

SCR7

SCR2

SCR3

SCR4

SCR5

SCR6

G6

G5

G4

G3

G2

G1

+

-

-

-

-

41

31

33

H1

H2

H3

H4

THERMOSTAT

PRIMARY

SECONDARY

R

FAN MOTOR

X1

X2

X2

207

209

36VAC

CT

R

R

W

Y

Y

32B

POWER

RECEPTACLE

21A

2A

4A

31A

32A

FEEDER

WIRE

BLUE

WHITE

15 AMPS

10 AMPS

15 AMPS

CR1

CR1

-

40

32D

40

30A

30B

30

32

SNUBBER

BOARD

SUPPRESSOR

BOARD

OUTPUT

SWITCH

12 PIN

16 PIN

1

1

6

8

7

12

91

6

202

202A

32B

32C

30C

42

J7V

J7A

201

T1

T2

S1

R6

CB1

CB2

CB3

S3

S5

CUSTOMER

GROUND

315

316

320A

324

375

302

304

319

318

320

320A

322

A

B

C

D

E

F

G

H

I

J

K

L

M

N

PHYSICAL LAYOUT

(REAR VIEW)

316

315

S2

1

2

3

4

5

6

7

8

9

10

11

12

MODE

SWITCH

366

361

362

363

364

VOLTMETER

LN-9/NA-5

(SHOWN "ON")

OUTPUT CONTROL

(SHOWN IN "LOCAL")

ON

OFF

115

VAC

115

VAC

42

VAC

1

11

12

13

5

6

J4

G1

G2

G3

G4

G5

G6

300

310

311

312

313

1

2

3

4

5

6

7

8

9

11

12

J2

1

2

3

4

5

6

7

8

9

J1

1

2

3

4

5

6

J5

J6

7

8

VOLTMETER

P.C. BOARD

AMMETER

P.C. BOARD

7

8

9

1

2

5

6

3

4

J8

10

313

312

311

310

300

G6

G5

G4

G3

G2

G1

1

2

3

4

5

6

7

8

9

11

12

J10

10

10

1

2

3

4

5

6

1

2

10

1

2

3

4

5

6

34

J9

12

34

56

7

8

J11

1

2

34

5

6

7

8

91

0

1

1

12

13

14

15

16

J7A,J7V,J13

J5,J9

J1,J8

J2,J10

J4,J11

6 PIN

1

8

7

14

14 PIN

J3

5

8

6

2

3

4

7

9

10

14

13

J3

1

12

11

J3

8/300W

8/300W

WIRE FEEDER

VOLTMETER

9

8

332A

330

2

3

4

7

10

14

15

16

NOTE: SINCE COMPONENTS OR CIRCUITRY OF A PRINTED CIRCUIT BOARD

MAY CHANGE WITHOUT AFFECTING THE INTERCHANGEABILITY OF A

COMPLETE BOARD. THIS DIAGRAM MAY NOT SHOW THE EXACT COMPONENTS

OR CIRCUITRY OF CONTROLS HAVING A COMMON CODE NUMBER.

INPUT

LINES

L3

H1

L2

INSULATE WITH TAPE

H2

H3

H4

L1

INPUT

LINES

L3

L1

H1

L2

H4

INSULATE WITH TAPE

H2

H3

575V/60HZ

460V/60HZ

230V/60HZ

INPUT

LINES

L3

L1

H1

L2

H4

INSULATE WITH TAPE

H2

H3

T1

T2

T3

A

B

C

4

5

6

7

8

9

T1

T2

T3

T1

T2

A

B

C

A

B

4

5

6

4

5

7

8

9

7

8

C6

9

T3

INPUT

LINES

L3

H1

L2

INSULATE WITH TAPE

H2

H3

L1

INPUT

LINES

L3

L1

H1

L2

INSULATE WITH TAPE

H2

H3

T1

T2

T3

4

5

6

7

8

9

T1

T2

T3

4

5

6

7

8

9

230/460/575/60 HZ MACHINES ONLY

J6,J12

2437

R3

ON

REMOTE

308A

307

+ELECTRODE

-ELECTRODE

308A

200

211

29

CONNECTIONS

N.A.

N.A. THIS PERMANENT CONNECTION IS

MADE AT THE MAIN TRANSFORMER

FOR 230/460, AND 230/460/575V

MACHINES ONLY.

INPUT

LINES

L3

H1

L2

INSULATE WITH TAPE

H2

H3

L1

T1

T2

T3

4

5

6

7

8

9

12

10

11

GND

INPUT

LINES

L3

L1

H1

L2

INSULATE WITH TAPE

H2

H3

T1

T2

4

5

7

8

6

9

T3

GND

12

10

11

208V 50 / 60 HZ

416V 50 / 60 HZ

208/416V 60 HZ MACHINES ONLY

230/460V 60HZ MACHINES ONLY

460V 60HZ

230V 60HZ

DC-650 PRO WIRING DIAGRAM

NOTE: This diagram is for reference only. It may not be accurate for all machines covered by this manual. The specific diag

ram for a particular code is pasted inside

the machine on one of the enclosure panels. If the diagram is illegible, write to the Service Department for a replacement. G

ive the equipment code number..