Lincoln Electric IM774 CobraMAX K2252-1 & K2252-2 User Manual

Page 17

CobraMAX™ Owner's Manual - Page 7

Section E

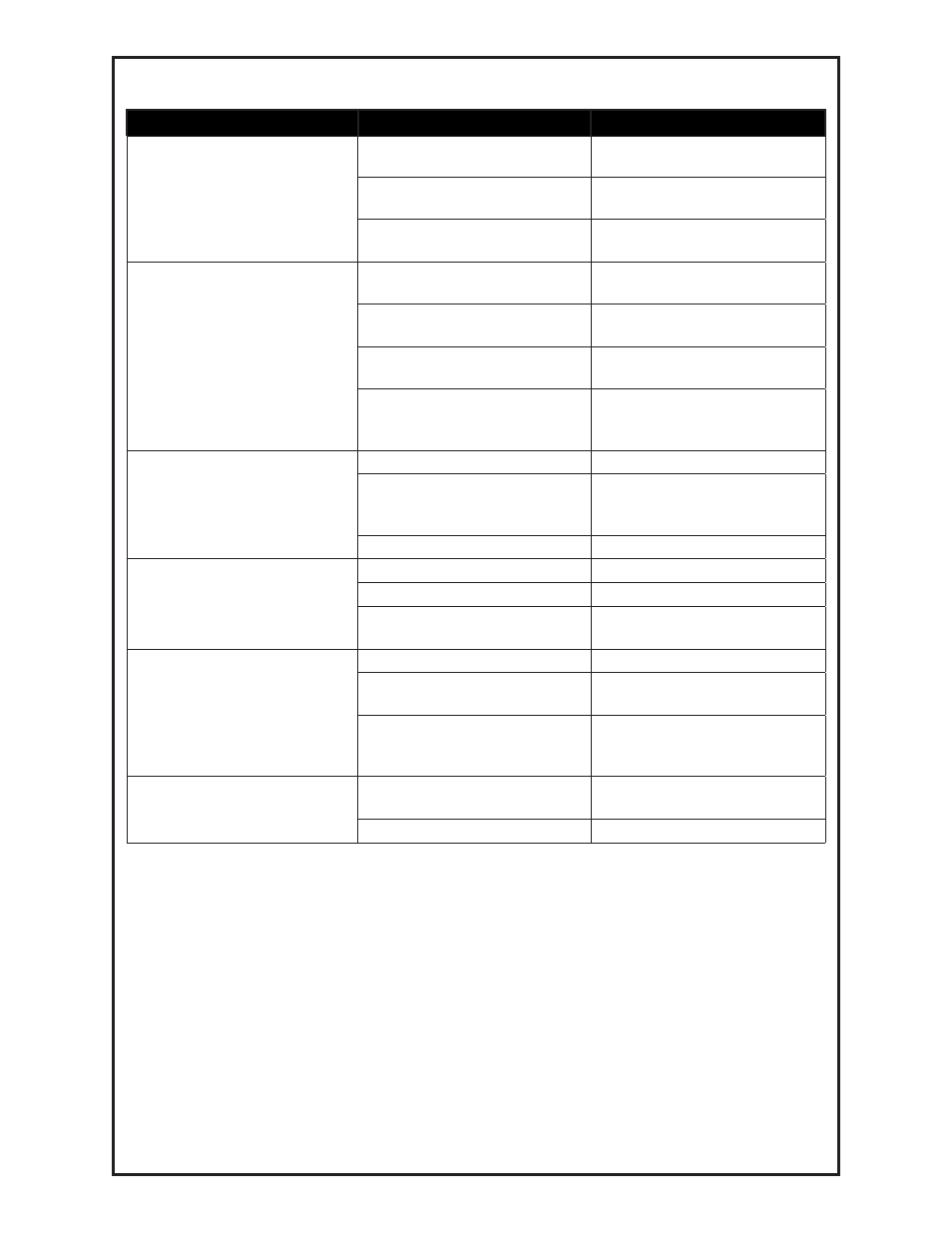

Troubleshooting

Trouble

Cause

Remedy

No wire feed at gun,

feeder not operating, i.e., no

slave motor or brake solenoid.

115 VAC Control fuse in feeder/

Control box blown.

Replace fuse.

Micro-switch defective/not

being activated.

Replace switch. Check switch

for operation.

Broken electrical cable.

Check micro-switch wires for

continuity.

No wire feed at gun, feeder

operating properly

24 VAC Control fuse in feeder/

Control box blown.

Check motor leads for shorts;

then replace fuse.

Bad Potentiometer.

Check potentiometer with

meter.

Broken Electrical Cable

Check motor and potentiometer

for continuity.

Bad Speed control/PCB.

See specific cabinet/control

box owners manual for speed

control operation.

Wire feeds, but welding wire is

not energized.

Loose or no cable connections.

Check all power connections.

Contactor control cable loose or

in wrong position

Check power supply owners

manual for location and type of

contactor signal required.

Welding power source.

Check power source.

Wire feeds erratically.

Dirty or worn conduit.

Blow out or replace conduit.

Wrong size contact tip.

See contact tip table.

Idler roll stuck.

Check for lock washer under

idler roll, or replace if damaged.

Wire feeds one speed only.

Bad potentiometer.

Check with meter.

Broken electrical cable.

Check potentiometer wires for

continuity or short.

Bad speed control.

See specific cabinet/control

owners manual for speed

control operation.

Wire walks out of the drive

rolls.

Idler roll upside-down.

Place groove in idler roll toward

top.

Rear wire guide missing.

Replace wire guide.