Contact tips, Spring loaded tips, Heavy duty contact tip - 3/8" diameter – Lincoln Electric IM774 CobraMAX K2252-1 & K2252-2 User Manual

Page 15: Gas cups, Spring loaded contact tip - 3/8" diameter

CobraMAX™ Owner's Manual - Page 5

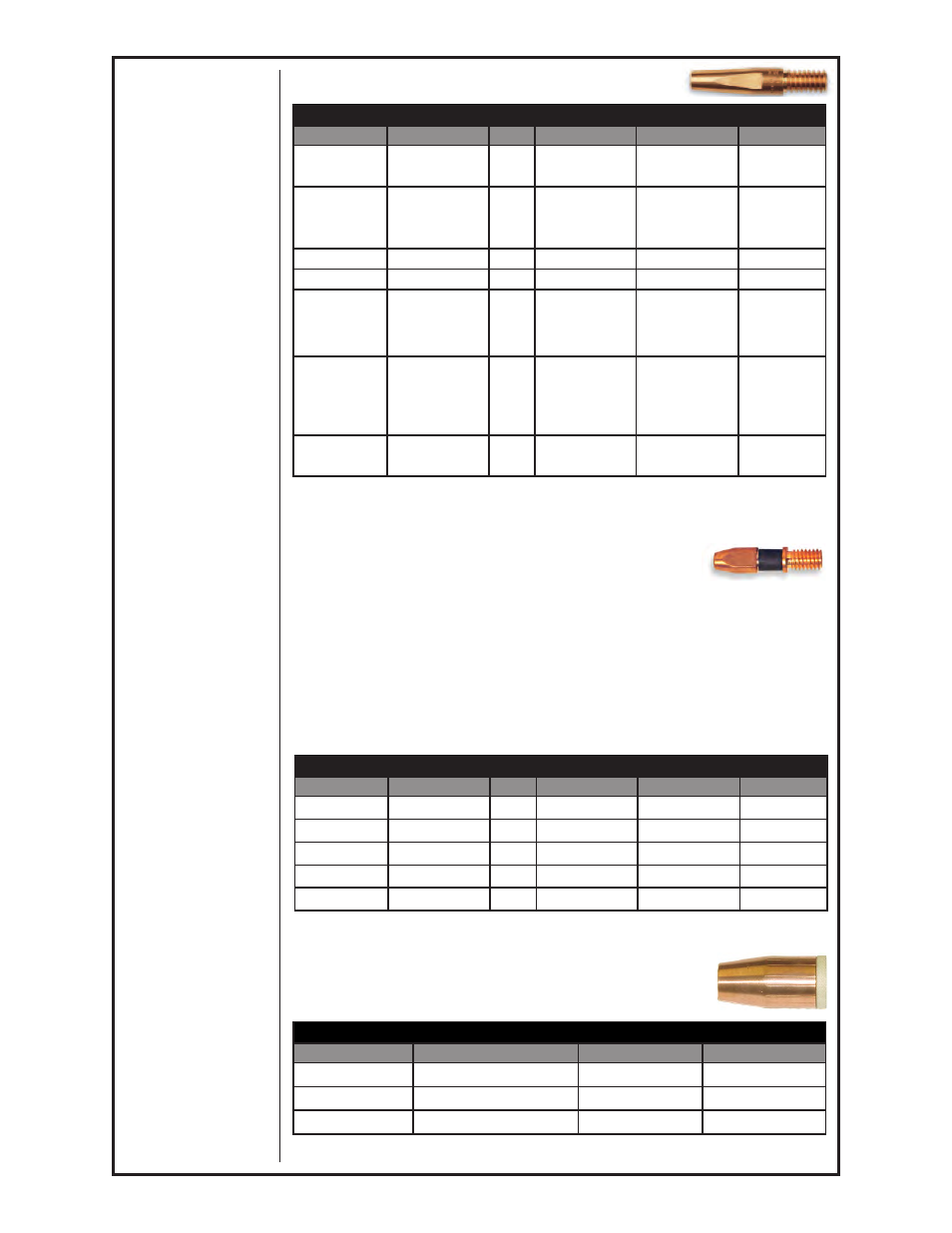

Contact Tips

Heavy Duty Contact Tip - 3/8" Diameter*

Wire Size

Tip ID

Arc

Tip Length

MK Part No LE Part No

.030” (0.8mm) .040” (1.0mm) Spray 1.57” (39.9mm) 621-0390-25

KP2217-1B1

Short 1.82” (46.2mm) 621-0396-25

--

.035” (0.9mm) .045” (1.1mm) Spray 1.57” (39.9mm) 621-0391-25

KP2217-2B1

621-0391-250

†

621-0391-500

††

.035" (0.9mm) .045" (1.1mm)

Short 1.82” (46.2mm) 621-0397-25

--

.045" (1.1mm) .054" (1.37mm) Short 1.82” (46.2mm) 621-0398-25

--

3/64” (1.2mm)

(5356 Alloy)

.054” (1.37mm) Spray 1.57” (39.9mm) 621-0392-25

KP2217-3B1

621-0392-250

†

621-0392-500

††

3/64” (1.2mm)

(4043 Alloy)

.060” (1.5mm)

Spray 1.57” (39.9mm) 621-0393-25** KP2217-4B1

621-0393-250

†

621-0393-500

††

1/16” (1.6mm) .074” (1.9mm) Spray 1.57” (39.9mm) 621-0394-25

KP2217-5B1

.085” (2.16mm) Spray

621-0395-25

*

Use of tip removal tool is recommended

†

Also

sold in quantities of 250

**This size tip furnished with gun

† †

Also

sold in quantities of 500

Gas Cups

Cup Size

Cup I.D.

MK P/N

LE P/N

No. 6

3/8" (9.5mm)

621-0420

KP2249-1

No. 8*

1/2" (15.8mm)

621-0421

KP2250-1

No. 10

5/8" (15.8mm)

621-0422

KP2251-1

*standard - furnished with gun

Gas Cups

Spring Loaded Contact Tip - 3/8" Diameter*

Wire Size

Tip ID

Arc

Tip Length

MK Part No LE Part No

.030” (0.8mm) .040” (1.0mm) Spray 1.57” (39.9mm)

621-0331

KP2662-1

.035” (0.9mm) .045” (1.1mm) Spray 1.57” (39.9mm)

621-0332

KP2662-2

3/64” (1.2mm) .054” (1.37mm) Spray 1.57” (39.9mm)

621-0333

KP2662-3

3/64” (1.2mm) .060” (1.5mm) Spray 1.57” (39.9mm)

621-0334

KP2662-4

1/16” (1.6mm) .074” (1.9mm) Spray 1.57” (39.9mm)

621-0335

KP2262-5

*

Use of tip removal tool is recommended

Spring Loaded Tips

The use of the Spring Loaded Tips has shown to improve wire to tip

contact significantly, especially while welding aluminum in DC Pulse Mode.

Incorporating a wrap-around spring material, a ceramic "puck" pushes up

against the wire forcing the wire to make 100% positive contact with the

internal face of the contact tip.

The constant touching of the wire to the tip eliminates "electrical gaps" in the

welding voltage sensing loop, which many welding power sources utilize for

sensing arc voltage values.