Welder troubleshooting, Troubleshooting, Trouble causes what to do – Lincoln Electric IM631 CLASSIC 300 D User Manual

Page 24: Classic 300d

E-2

TROUBLESHOOTING

CLASSIC 300D

E-2

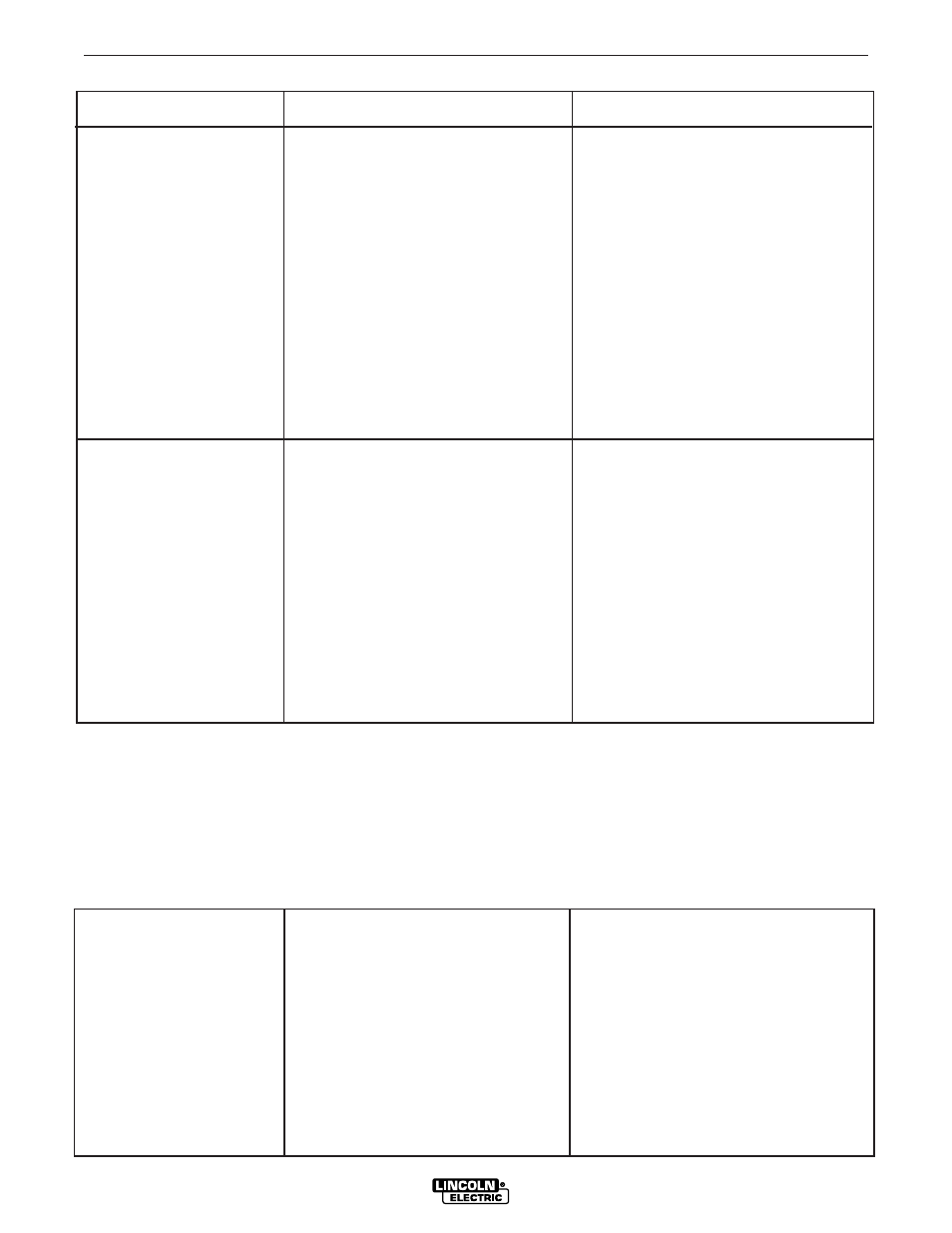

WELDER TROUBLESHOOTING

TROUBLE

CAUSES

WHAT TO DO

1.

Machine fails to hold

a.

Rough or dirty commutator.

a.

Commutator should be turned or

the output (heat) consistently.

cleaned.

b.

Brushes may be worn down to

b.

Replace brushes.

limit.

c.

Field circuit may have variable

c.

Check field current with ammeter to

resistance connection or

discover varying current. This

intermittent open circuit due to

applies to both the main generator

loose connection or broken wire.

and exciter.

d.

Electrode lead or work lead

d.

Tighten all connections.

connection may be poor.

e.

Wrong grade of brushes may

e.

Use Lincoln brushes.

have been installed on generator.

f.

Field rheostat may be making

f.

Inspect and clean the rheostat.

poor contact and overheating.

2.

Welder starts but fails

a.

Generator or exciter brushes

a.

Be sure that all brushes bear on the

to generate current.

may be loose or missing.

commutator and have proper spring

tension.

b.

Exciter may not be operating.

b.

Check exciter output voltage with

voltmeter or lamp.

c.

Field circuit of generator or

c.

Check for open circuits in rheostat,

exciter may be open.

field leads, and field coils. Check

rectifier bridge.

d.

Exciter may have lost excitation.

d.

Flash fields. (1) Check flashing

diode at 5 o

’

clock brushholder in

generator.

e.

Series field and armature circuit

e.

Check circuit with ringer or voltmeter.

may be open-circuited.

(1)

FLASHING THE FIELDS:

1.

Stop the engine welder and remove the cover from the exciter.

2.

Turn the

“

Fine Current Adjustment

”

(rheostat) to

“

100

”

on the dial.

3.

Using a 12 volt automotive battery, connect it

’

s negative terminal to the negative brushholder. The

negative brushholder is the one nearest to the rotor lamination. See the wiring diagram. With the

engine NOT running, touch the positive battery terminal to the positive brushholder. Remove the

battery from the circuit.

4.

Replace the exciter cover. Start the welder and the generator voltage should build up.

3.

Welding arc is loud and

a.

Current setting may be too high.

a.

Check setting and current output with ammeter.

spatters excessively

b.

Polarity may be wrong.

b.

Check polarity. Try reversing polarity or try an

electrode of the opposite polarity.

4.

Welding current too great or too

a.

Exciter output low causing low output

a.

Check exciter field circuit.

small compared to indication on

compared to dial indication.

the dial.

b.

Operating speed too low or too high.

b.

Adjust speed with screw stops at throttle linkage.

(High idle - 1800 RPM, Low idle - 1375 RPM)

5.

Arc continuously pops out.

a.

“

Current Range Selector

”

switch may be

a.

Set the switch at the center of the current range

set at an intermediate position.

desired.