Troubleshooting, Caution – Lincoln Electric IM474 IDEALARC DC-400 User Manual

Page 27

E-2

TROUBLESHOOTING

E-2

IDEALARC® DC-400

Observe all Safety Guidelines detailed throughout this manual

If for any reason you do not understand the test procedures or are unable to perform the tests/repairs safely, contact your

Local Lincoln Authorized Field Service Facility for technical troubleshooting assistance before you proceed.

CAUTION

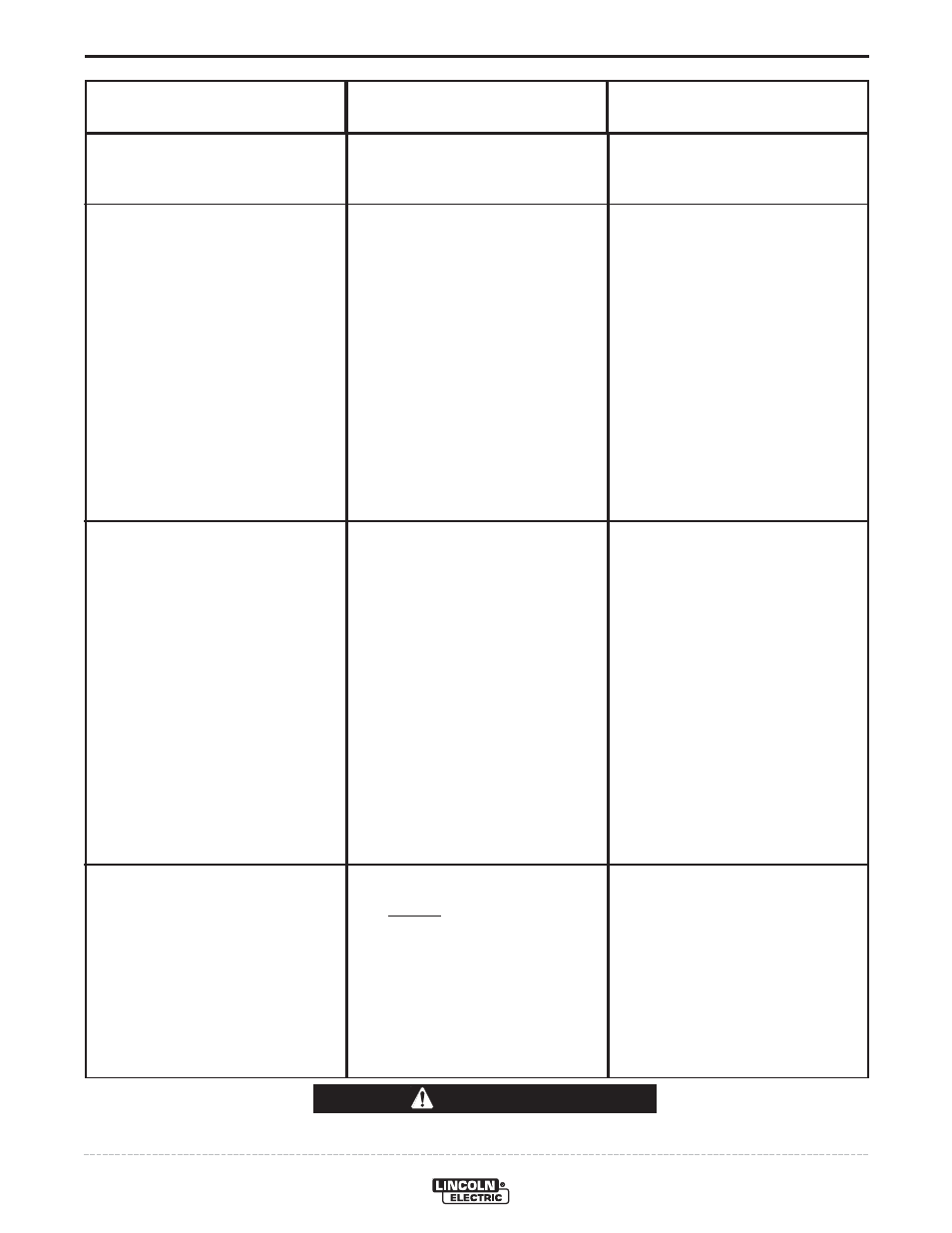

PROBLEMS

(SYMPTOMS)

POSSIBLE

CAUSE

RECOMMENDED

COURSE OF ACTION

Input contactor (CR1) chatters.

Machine input contactor does not

operate.

Machine input contactor operates,

but no output when trying to weld.

Machine has minimum output and no

control.

1. Faulty input contactor (CR1).

2. Low line voltage.

1. Supply line fuse blown.

2. Contactor power circuit dead.

3. Broken power lead.

4. Wrong input voltage.

5. Open input contactor coil.

6. POWER “I/0” switch (S1) not

closing.

1. Trigger circuit between #2 and #4

leads is not being closed.

2. Electrode or work lead loose or

broken.

3. Open main transformer (T1) pri-

mary or secondary circuit.

4. Defective Control PC Board.

5. Primary or secondary thermostats

open.

1. Terminals 75, 76 or 77 grounded

to positive output.

1. Repair or Replace.

2. Check input power.

1. Replace if blown - look for reason

first.

2. Check control transformer T2 and

associated leads.

3. Check input voltage at contactor.

4. Check voltage against instruc-

tions.

5. Replace coil.

6. Replace switch.

1. Make sure trigger circuit is being

closed.

2. Repair Connection.

3. Repair.

4. Replace. See Procedure for

Replacing PC Boards.

5. Amber thermal protection light is

on: Check for overheating; make

sure fan is operating and there is

no obstruction to free air flow.

1. Check 75, 76, or 77 for ground to

positive output circuit. Nearly

zero ohms to ground indicates a

grounded circuit. A value greater

than a few thousand ohms is nor-

mal. Self-restraining fuses on PC

Board automatically reset within a

few seconds after ground is

cleared.