Operation – Lincoln Electric IM859 POWER MIG 350MP User Manual

Page 19

B-6

B-6

OPERATION

POWER MIG

®

350MP

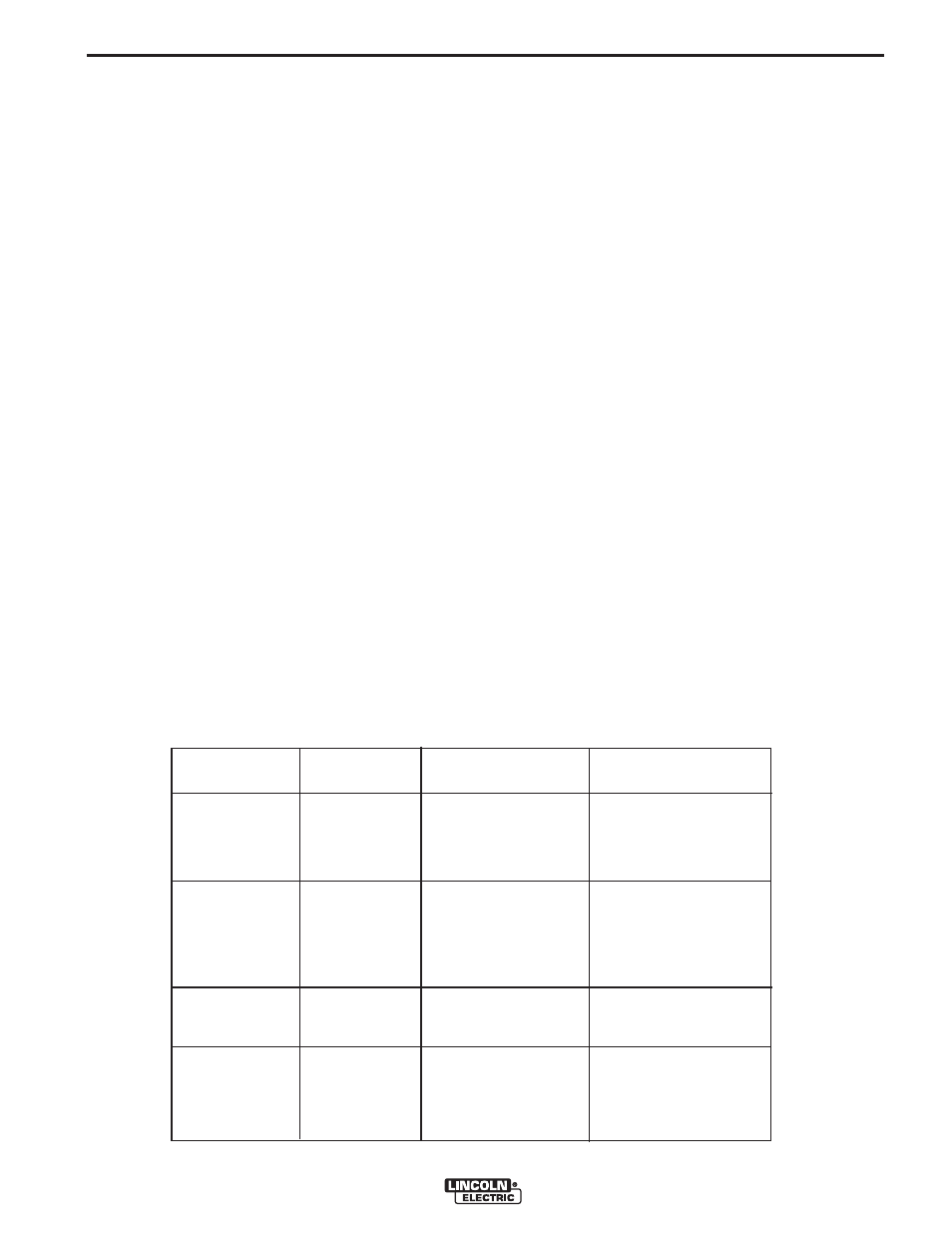

Arc Control (See Table B.2)

There are no specific unit values offered because the setting

of this feature largely depends upon operator preference.

Arc Control has a different effect on the character of the arc

depending upon the welding process applied.

In SMAW (STICK mode), arc control adjusts the arc force. It

can be set to the lower range for a soft and less penetrating

arc characteristic (negative numeric values) or to the higher

range (positive numeric values) for a crisp and more pene-

trating arc. Normally, when welding with cellulosic types of

electrodes (E6010, E7010, E6011), a higher energy arc is

required to maintain arc stability. This is usually indicated

when the electrode sticks to the work-piece or when the arc

pops-out during manipulative technique. For low hydrogen

types of electrodes (E7018, E8018, E9018, etc.) a softer arc

is usually desirable and the lower end of the Arc Control

suits these types of electrodes. In either case the arc con-

trol is available to increase or decrease the energy level

delivered to the arc.

In GMAW-S, the short-circuiting mode of metal transfer, the

Arc Control features the ability to increase or decrease the

energy level at the arc. Setting the arc control from 1 to 10

decreases energy, and setting the Arc Control from 0 to –10

increases the energy delivered to the arc.

Solid carbon steel electrodes in a range from .025"- .045" (.6

mm – 1.1 mm) are nominally used, and the shielding gas

blend for GMAW-S is usually 100% carbon dioxide or a

blend of argon and carbon dioxide. The Arc Control in this

scenario is set to control the droplet size and more pinch is

added (increasing pinch reduces energy to the arc) to

achieve the "bacon frying" sound associated with this mode

of metal transfer.

Carbon steel electrodes employed in GMAW-S usually per-

form best when the droplet size is regulated by pinch to

reduce the droplet size transferred with each short-circuit

event.

When welding with solid stainless steel types of electrodes it

is usually desirable to increase the energy delivered to the

arc. High percentage argon blends with a 2 % addition of

oxygen or a three part shielding gas blend comprised of

90% Helium + 7.5% Argon + 2.5 % carbon dioxide are usu-

ally employed. The added energy is associated, in this sce-

nario, with increasing the inductance (negative numeric val-

ues). By adding to the energy level the weld bead appear-

ance improves – spatter levels decrease and wetting action

at the toes of a fillet weld increases. The arc is softer with

the higher inductance setting and the arc lends itself to

faster travel speed.

In GMAW-P, the pulsed spray mode of metal transfer, the

Arc Control is, once again, used to increase and decrease

the focus of the energy delivered to the arc. Increasing the

setting in the range of +1 to +10 results in an increase in

pulsed frequency, and the effect is to narrow the arc cone

and concentrate the available energy to a smaller area.

Decreasing the Arc Control setting from –1 to –10 results in

a reduction of pulsed frequency – the result is a broader arc

cone, which creates a wider weld bead.

Important to note here is that if a component of a pulsed

waveform is increased, then another must be decreased.

Adding pulsed frequency through an increase in the Arc

Control setting, then also results in a proportional decrease

in background current. If this were not the case, then the arc

would become too long, with too much energy, and the arc

would be unusable.

PROCESS

ARC SETTING

APPLICATION

AND

CONTROL

RESULT

SYNONYM

SMAW (STICK)

Arc Force

Lower (-1 to -10) for

Minus settings are soft

low hydrogen types of

and buttery for low

electrodes. Higher (+1

hydrogen electrodes.

to +10) for cellulosic

Plus settings are harsh

and other types.

and digging for other

types of electrodes.

GMAW – S (Short

Inductance or

Setting -1 to -10 for

The minus settings

circuiting metal

Pinch Control

softer higher energy

result a more fluid

transfer

arc. Setting +1 to +10

puddle and larger

for a crisper lower

droplet size. The postive

energy arc.

settings reduce the

droplet size and reduce

energy to the arc.

GMAW – P (Pulsed

Pulsed frequency

Minus settings reduces

Wider arc cone and

spray metal transfer)

control

frequency. Plus

weld bead. Narrower

settings increase

arc cone and narrower

frequency. weld

bead.

Pulse – on –Pulse™

Pulsed frequency

Minus settings result in

Minus settings result in

(Aluminum Only)

array control

lower array frequency

a wider bead with more

and the plus settings

distinct ripples. Plus

increase the array

settings narrow the

frequency.

resultant bead and the

ripples are less distinct.

PROCESS

ARC SETTING

APPLICATION

AND

CONTROL

RESULT

SYNONYM

SMAW (STICK)

Arc Force

Lower (-1 to -10) for

Minus settings are soft

low hydrogen types of

and buttery for low

electrodes. Higher (+1

hydrogen electrodes.

to +10) for cellulosic

Plus settings are harsh

and other types.

and digging for other

types of electrodes.

GMAW – S (Short

Inductance or

Setting -1 to -10 for

The minus settings

circuiting metal

Pinch Control

softer higher energy

result a more fluid

transfer

arc. Setting +1 to +10

puddle and larger

for a crisper lower

droplet size. The postive

energy arc.

settings reduce the

droplet size and reduce

energy to the arc.

GMAW – P (Pulsed

Pulsed frequency

Minus settings reduces

Wider arc cone and

spray metal transfer)

control

frequency. Plus

weld bead. Narrower

settings increase

arc cone and narrower

frequency. weld

bead.

Pulse – on –Pulse™

Pulsed frequency

Minus settings result in

Minus settings result in

(Aluminum Only)

array control

lower array frequency

a wider bead with more

and the plus settings

distinct ripples. Plus

increase the array

settings narrow the

frequency.

resultant bead and the

ripples are less distinct.

PROCESS

ARC SETTING

APPLICATION

AND

CONTROL

RESULT

SYNONYM

SMAW (STICK)

Arc Force

Lower (-1 to -10) for

Minus settings are soft

low hydrogen types of

and buttery for low

electrodes. Higher (+1

hydrogen electrodes.

to +10) for cellulosic

Plus settings are harsh

and other types.

and digging for other

types of electrodes.

GMAW – S (Short

Inductance or

Setting -1 to -10 for

The minus settings

circuiting metal

Pinch Control

softer higher energy

result a more fluid

transfer

arc. Setting +1 to +10

puddle and larger

for a crisper lower

droplet size. The postive

energy arc.

settings reduce the

droplet size and reduce

energy to the arc.

GMAW – P (Pulsed

Pulsed frequency

Minus settings reduces

Wider arc cone and

spray metal transfer)

control

frequency. Plus

weld bead. Narrower

settings increase

arc cone and narrower

frequency. weld

bead.

Pulse – on –Pulse™

Pulsed frequency

Minus settings result in

Minus settings result in

(Aluminum Only)

array control

lower array frequency

a wider bead with more

and the plus settings

distinct ripples. Plus

increase the array

settings narrow the

frequency.

resultant bead and the

ripples are less distinct.

PROCESS

ARC SETTING

APPLICATION

AND

CONTROL

RESULT

SYNONYM

SMAW (STICK)

Arc Force

Lower (-1 to -10) for

Minus settings are soft

low hydrogen types of

and buttery for low

electrodes. Higher (+1

hydrogen electrodes.

to +10) for cellulosic

Plus settings are harsh

and other types.

and digging for other

types of electrodes.

GMAW – S (Short

Inductance or

Setting -1 to -10 for

The minus settings

circuiting metal

Pinch Control

softer higher energy

result a more fluid

transfer

arc. Setting +1 to +10

puddle and larger

for a crisper lower

droplet size. The postive

energy arc.

settings reduce the

droplet size and reduce

energy to the arc.

GMAW – P (Pulsed

Pulsed frequency

Minus settings reduces

Wider arc cone and

spray metal transfer)

control

frequency. Plus

weld bead. Narrower

settings increase

arc cone and narrower

frequency. weld

bead.

Pulse – on –Pulse™

Pulsed frequency

Minus settings result in

Minus settings result in

(Aluminum Only)

array control

lower array frequency

a wider bead with more

and the plus settings

distinct ripples. Plus

increase the array

settings narrow the

frequency.

resultant bead and the

ripples are less distinct.

TABLE B.2-Arc control settings by process