Operation, Product description, Controls and settings – Lincoln Electric IM859 POWER MIG 350MP User Manual

Page 15

B-2

B-2

OPERATION

POWER MIG

®

350MP

PRODUCT DESCRIPTION

The POWER MIG

®

350MP is a complete semiauto-

matic multi-process DC arc welding machine offering

CV and CC DC welding. It is rated for 350 amps, 32

volts at a 60% duty cycle. The standard machine is

equipped to weld CC-Stick, CC-GTAW, CV-FCAW,

and synergic and non-synergic CV-GMAW / GMAW-P

and Pulse-on-Pulse and Power Mode welding

processes. See the descriptions for Pulse on

Pulse™and Power Mode welding processes later in

this section.

Mode #5 and mode #6 are non-synergic CV GMAW

modes for bare and flux cored wires, respectively. In

these modes, the user presets the wire feed speed

(WFS) on the left meter and the welding voltage on

the right. These two settings are independent; that is,

if the WFS is changed the voltage will remain con-

stant, or vice versa.

All of the other mode numbers designated as "CV" are

synergic. Again, WFS is shown on the left meter and

voltage is shown on the right meter. However, in using

these modes, the WFS is preset and the voltage is

preset only once. Now, when the WFS is changed, the

voltage will change with it, so that the arc appearance

and arc length will stay the same without the necessity

to re-adjust the voltage.

The modes shown as "GMAW-P" or " GMAW-PP" are

all synergic pulsed modes. In these modes WFS is

shown on the left meter and "Trim" is shown on the

right meter. The user adjusts WFS to obtain an arc

with the correct arc energy for the material thickness

being welded. The Trim, which is adjustable from val-

ues of 0.5 to 1.5, 1.00(Nominal) and up to 1.5 controls

the arc length. Higher values of Trim give longer arc

lengths. Once the user has adjusted the Trim for one

WFS, the power supply will synergically change many

variables so that, as the WFS is changed, the arc

length and arc appearance will remain the same. The

synergic modes are usable with both push and push –

pull torches, as described later in this Manual. When

using a spool gun, however, although the synergic

pulsed modes are still accessible, they must be used

in a non-synergic manner as described in the

Accessory Section.

The digital microcomputer based control system

allows easy and accurate adjustment of weld parame-

ters through the multi-process panel located on the

front of the machine. The POWER MIG

®

350MP is

equipped with a 6-pin and 7-pin connector to allow

operation of a push-pull gun for feeding aluminum

wires, a spool gun, remotes, and a foot amptrol.

Other features

Optional kits are available for push-pull welding, spool

gun operation, push feeding of 3/64 aluminum with the

standard POWER MIG

®

350MP gun and wire feeder.

A Dual Cylinder Mounting Kit is also offered.

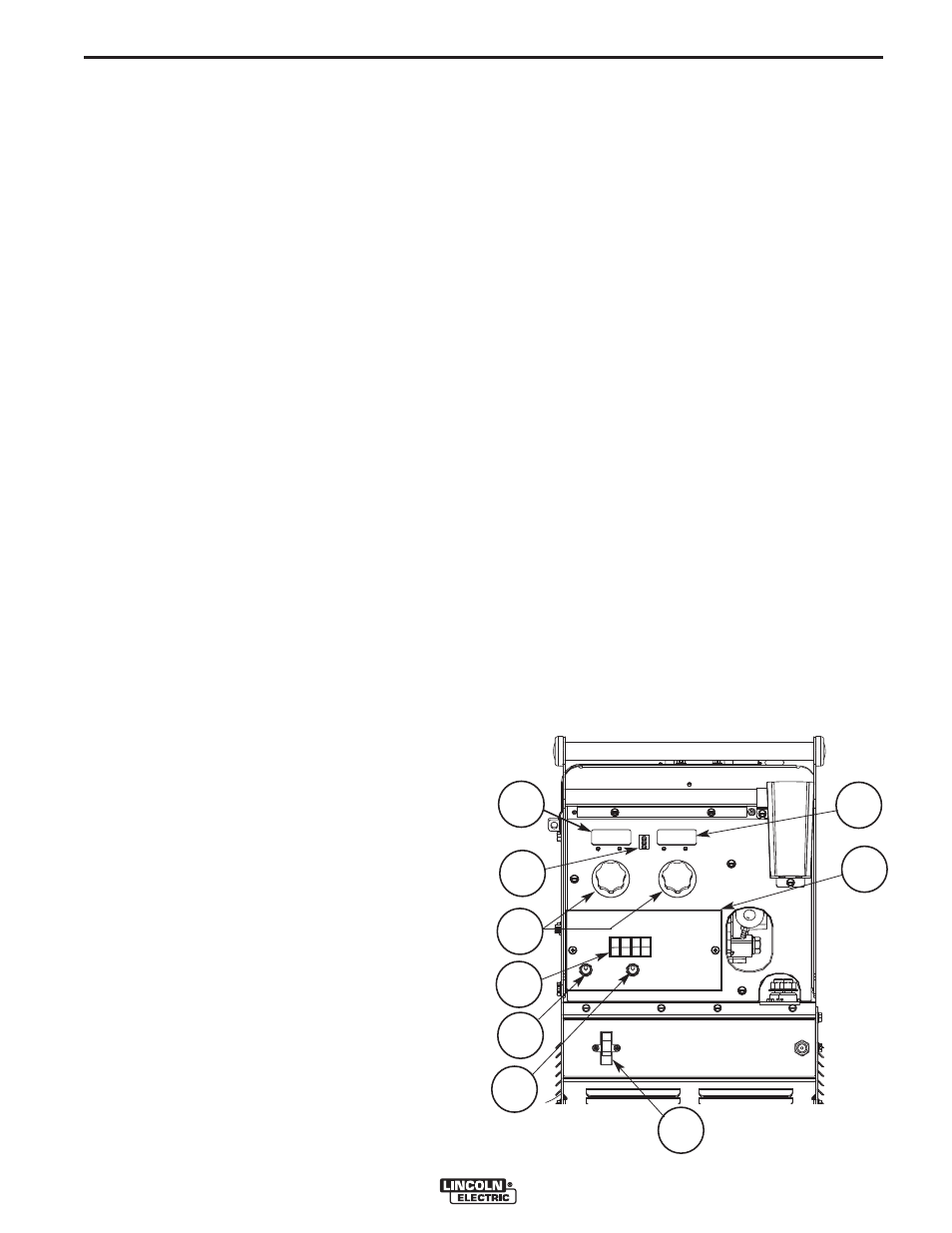

CONTROLS AND SETTINGS

(See Figure B.1)

1. WIRE FEED SPEED (WFS) / AMP METER - This

meter displays either the WFS or current value

(Amps) depending on the status of the machine.

Located below the display is the text "WFS" and

"Amps." An LED light is illuminated to the left of one

of these units to indicate the units of the value dis-

played on the meter.

• Prior to CV operation, the meter displays the

desired preset WFS value.

• Prior to CC-Stick and CC-GTAW operation, the

meter displays the preset current value.

• During Welding, the meter displays actual average

amps.

• After welding, the meter holds the actual current

value for 5 seconds. During this time, the display

is blinking to indicate that the machine is in the

"Hold" period. Output adjustment while in the

"Hold" period results in the "prior to operation"

characteristics stated above.

• After the 5 second "Hold" period, the meter dis-

plays the set WFS (CV modes) or Amp (CC

modes) value.

Figure B.1

1

2

5

5B

5A

5C

6

4

3