Davey PRIME JET 240 PUMPS AND PRESSURE SYSTEMS User Manual

Page 6

Davey recommend the use of overloads which also have the

ability to detect “single phasing” or “dropped phase” conditions in

the power supply.

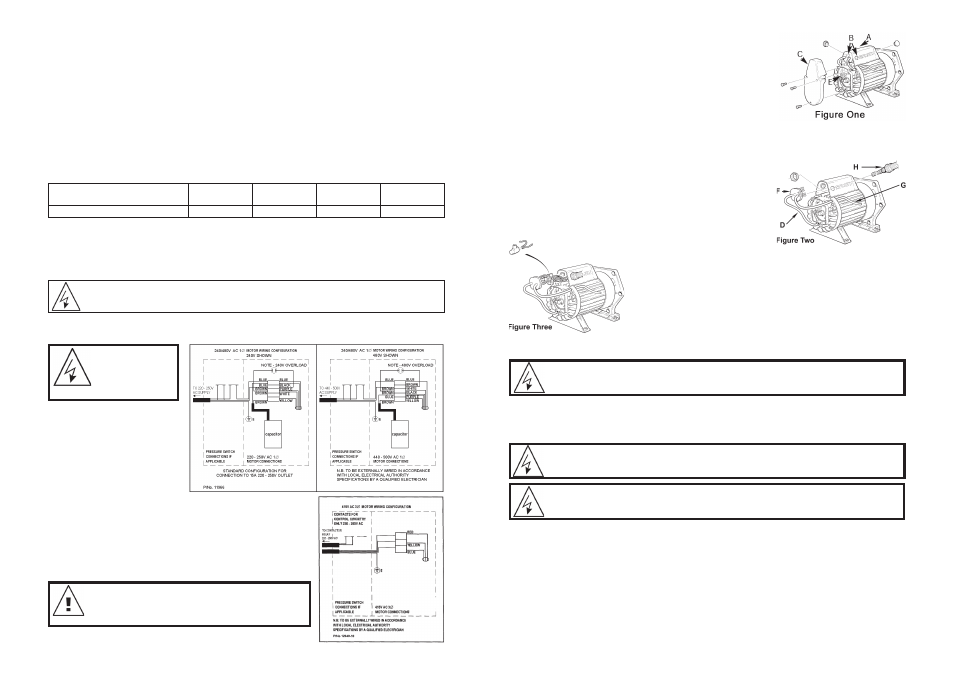

Three phase Prime Jet 240 models have been designed to allow

for connection either side of the Capacitor Cover (marked “A” in

figure one) on the motor. (NOTE: Three phase motors do not have

capacitors fitted in the Capacitor Cover).

This is achieved by way of either of the two 19mm access holes

(marked “B” in figure one). The access holes are designed to

accept most standard cable grommets. The unused hole can be sealed by inserting the plug

enclosed with the pump. To connect a three phase Pressure Pump start by removing the Terminal

Cover (“C”)

A short four core flex (“D”) is fitted from the motor terminals (“E”).

This lead is inserted through the blanking grommet (“F”).

Pressure switch or other control leads (“G”) can be fitted as well.

Incoming power (“H”) can be fitted through the preferred access

hole, and terminated as shown in Figure Three. A termination kit

is available if required.

Insert the blanking grommet (“F”) into the capacitor cover (“A”). Fix

the short lead (“D”) into the path provided in the non-drive endshield

and replace the terminal cover (“C”).

IMPORTANT NOTE: THREE PHASE MODELS ONLY

When the unit is connected and operating the phase balance should be checked. This should be

within 5% variation. “Rolling” the leads may help to improve a small unbalance, but major phase

unbalance will usually be attributed to an input power unbalance. This must be addressed before

the pump is used.

ADDITIONAL NOTES ON ELECTRICAL CONNECTION

1. If the electrical fittings in your area make it necessary to remove the plug fitted to single phase

motors, care should be taken to ensure that the earth conductor is properly connected to

earth.

2. Long extension leads should be avoided as they often have insufficient current carrying

capacity to run electric motors; hence they can cause substantial voltage drop and operating

problems.

3. The minimum voltage at the electric motor must not fall below 216 Volts for 220/250V single

phase supply or 432 Volts for 480V single phase supply or 374 Volts for 3 phase supply.

Supply voltages below these limits may cause motor failure which is not claimable under

guarantee.

DELIVERY PIPING FOR SHALLOW OR DEEP WELL APPLICATIONS

It is recommended that a gate valve be fitted at the outlet of the pump. Pipe connection fittings

which allow convenient disconnection at a future time should be used. Polythene piping which

complies with the relevant Australian standard is recommended. However, select the grade of pipe

which has a pressure rating suitable for your application. Galvanised or PVC piping may also be

used providing the pressure rating is adequate.

The pressure delivered by your Prime Jet is reduced by the static delivery head (vertical height

from pump to outlet point) plus the friction loss caused by the piping itself. Static delivery head

reduces the available pressure from the pump by 10kPa (2psi) for every 1 metre (3.3 ft) of head.

The reduction in pressure due to pipe friction varies with the length, diameter and type of piping

used. The larger the diameter pipe the smaller the pressure drop.

The following pipe sizes are recommended for lengths up to 100m (330 ft).

MODEL

Outlet

Up to

Up to

Up to

Port Size

5mm (15”)

30M (100’)

100M (330’)

Prime Jet 240

30mm (1

1

/

4

”)

30mm (1

1

/

4

”)

40mm (1

1

/

2

”)

50mm (2”)

POWER CONNECTION

Single phase Prime Jet 240 units are supplied with a special 15 amp power plug which may only

be used with a 15 amp 220/ 250V power outlet (usually specially provided by an electrician).

Single phase Prime Jet 240 units may also be wired to a nominal 480V power supply, but must be

reconnected at the terminals under the terminal cover (refer Figure One on pg 7).

WIRING CONNECTIONS FOR SINGLE PHASE MOTORS

WIRING CONNECTIONS FOR THREE PHASE MOTORS

Prime Jet 240 units for connection to a nominal 415 Volt

3 phase supply must be wired with a contactor which has

quick trip (M10) rated overloads set at nameplate current. All

electrical connection work must be carried out by a suitable,

qualified electrician.

- 6 -

- 7 -

In addition, the overload fitted to the pump, is suitable for 240V only. 480V

overload is supplied in the bag in-which these instructions were supplied. All

this electrical work must be carried out by a suitably qualified electrician.

Before finalising wiring connections, check that motor rotates in direction of

arrow (clockwise when shaft is viewed from wiring connection end). To alter

rotation, change any two power leads at motor terminals.

Power connections and wiring must be carried out by an Authorised Electrician.

In accordance with AS 3350.2.41 we are obliged

to inform you that this pump is not to be used by

children or infirm persons and must not be used

as a toy by children.

Single phase

units should be

restricted to no

more than 20

starts per hour.

Note: Minimum three phase voltage supply at the motor must not fall below

374 volts, otherwise motor damage may result which is not claimable under

Guarantee.