Davey PRIME JET 240 PUMPS AND PRESSURE SYSTEMS User Manual

Page 3

To Check Correct Operation Of A Pressure System With Pressure Tank Fitted

Close gate valve at pump outlet. Allow pump to run and build up pressure until it switches off

automatically at the cut-out pressure setting on the pressure switch.

Open gate valve on pump outlet then turn on a tap in the outlet pipework. Pump should

automatically switch on at cut-in pressure switch setting. Refer to the “Pressure Switch Settings”

section earlier in these instructions.

MINIMUM OPERATING PRESSURE FOR DEEP WELL INSTALLATIONS

INJECTOR KIT NO.

427

428

468

566

567

568

569

Minimum Operating

Pressure kPa

280

280

280

270

270

290

240

Automatic Demand Response (ADR) - Setting up instructions

Deep Well installations require a certain minimum pump pressure to operate satisfactorily

(See Table above). With the adjustment screw on the ADR valve adjusted fully out run the pump.

Open gate valve (situated near pump) to discharge water freely until pressure on gauge drops

to minimum operating pressure as table above or until pump nears cavitation point. Screw ADR

valve adjustment in until pressure starts to rise. Open gate valve a little further, then readjust ADR

valve to maintain required minimum pressure on gauge. When gate valve is fully open and ADR

valve is maintaining operating pressure, adjustment is complete.

Once set, there should be no need to alter the setting of the ADR valve. ADR valve should be set

by discharging water adjacent to pump before connecting outlet pipework or pressure tank.

MINIMUM OPERATING PRESSURE FOR SHALLOW WELL INSTALLATIONS

Set the minimum operating pressures for Shallow Well pumps to the pressure indicated in the table

below.

INJECTOR KIT NO.

680

681

682

683

Minimum Operating

Pressure kPa

240

300

400

500

- 10 -

NOTE: The use of an engine powered pump to prime OFFSET deep well suction

pipes from the water source may simplify the priming process.

NOTE: Deep Well installation require a certain minimum reading on the

pressure gauge for the pump to operate satisfactory. If pump is allowed to

operate below this minimum operating pressure, cavitation may occur which

causes excessive pump wear, alternatively, prime may be lost.

NOTE: Shallow Well installations require a certain minimum reading on the

pressure gauge for the pump to operate satisfactorily. If pump is allowed to

operate below this minimum operating pressure, cavitation may occur which

causes excessive pump wear, alternatively, prime may be lost.

- 3 -

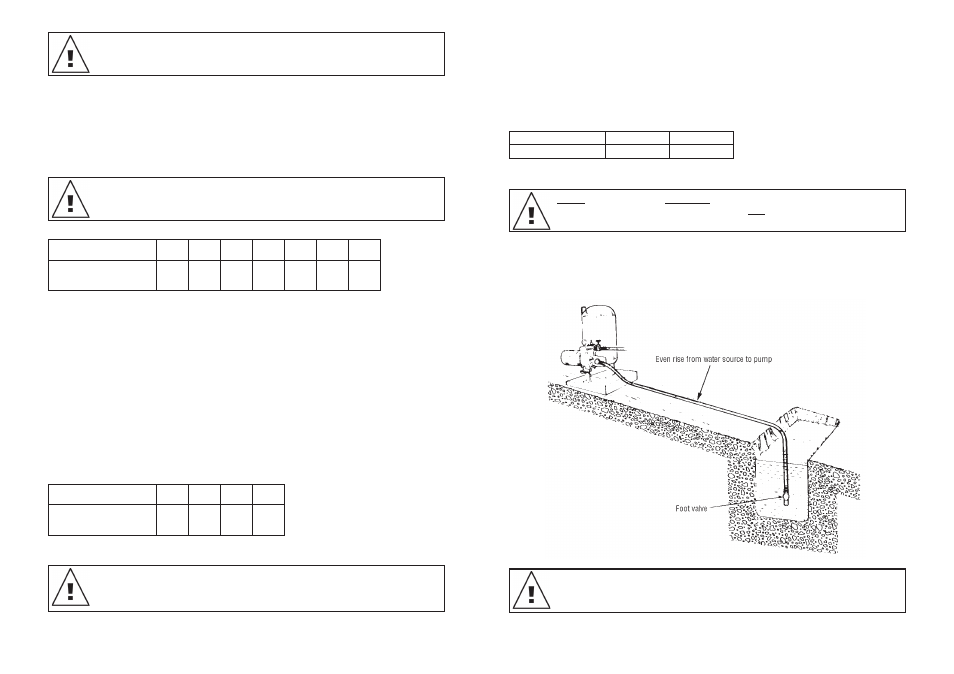

A foot valve must be used on the end of the suction pipe for below ground

installations or a check valve in the suction line for above ground water

sources (ie. tanks). For optimum pump operation and priming ensure that the

suction line is level or rises evenly from the water source to the pump.

Suction Piping

Polythene pipe is recommended for the pump suction as it provides flexibility, reduces the

transmission of pump noises and provides a convenient method of disconnecting the pump without

unions or the need to cut into the piping. For best performance situate the pump as close to the

water source as practical. To reduce pipe friction and maximise flow we recommend the following

Suction Pipe Sizes for the lengths indicated.

Suction Port size 1

1

/

2

” BSP

Suction Length

up to 10m

10m to 30m

Pipe size

40mm (1

1

/

2

”)

50mm (2”)

Use thread seal tape or pipe compound on all threaded pipe fittings or connections and ensure

they are leak free.

Suction piping should be laid so there is a constant rise from the water source to the pump.

Any high spots will cause air pockets to form and reduce the efficiency of the system as well as

creating priming difficulties.

Plumbing Details for ‘Shallow Well’ Installations

For Automatic Pressure System Installation.

NOTE: Suction leaks are the biggest cause of operating difficulties and are hard

to detect because the problem is air leaking into the pipe and there may be no

external sign of the leak.