0 maintenance, 1 troubleshooting, 2 maintenance procedures – Condec Source 3000 User Manual

Page 9: 1 front panel removal, 2 nitrogen cylinder assembly removal (pn 65622), 1 troubleshooting 3.2 maintenance procedures, Front panel removal, Nitrogen cylinder assembly removal (pn 65622)

Maintenance

5

3.0

Maintenance

3.1

Troubleshooting

3.2

Maintenance Procedures

This section outlines the mechanical repair procedures for the Source 3000 pressure source. The repair

procedures cover the major components and subassemblies which are critical to the proper functioning of the

calibrators and that will likely need periodic maintenance over the life of the unit. Only those persons who are

formally trained as skilled technicians should attempt to repair these units. All relevant safety precautions should

be observed due to the presence of high-pressure cylinders.

3.2.1

Front Panel Removal

Tools required:

Phillips screwdriver

1. Loosen and remove the ten screws (PN 60837) that secure the panel assembly to the enclosure.

2. Lift the panel by first grasping the regulator knob and Port 1, then grasping under the panel edges.

Ensure that the flexible pressure cable does not catch or snag.

3. Gently set the panel assembly on a bench top. It can be rested on the panel bottom and regulator edge

with the panel tilted at an angle from its vertical.

3.2.2

Nitrogen Cylinder Assembly Removal (PN 65622)

Condec strongly recommends that the internal nitrogen supply cylinder be pressure-tested and re-certified every

five years from date cylinder was manufactured per U.S. DOT. 3AL Regulation, Title 49 CFR, parts 173 and 178.

Tools required:

7/16" wrench

Phillips screwdriver

1-1/8" wrench

3/8" wrench

Procedure:

1. Vent any remaining gas from the cylinder to atmosphere.

2. Remove front panel from its enclosure as described in Section 3.2.1 and carefully set on a bench top.

3. Using a 7/16" wrench, remove flexible tubing (PN 65384) from the cylinder elbow.

4. Remove the 4 mounting nuts and 2 clamps for the cylinder.

5. Remove the cylinder assembly.

6. If installing a new cylinder, remove the fitting/elbow assembly and Teflon seal and inspect for any

damage. If there is no damage, reuse these items on the new cylinder.

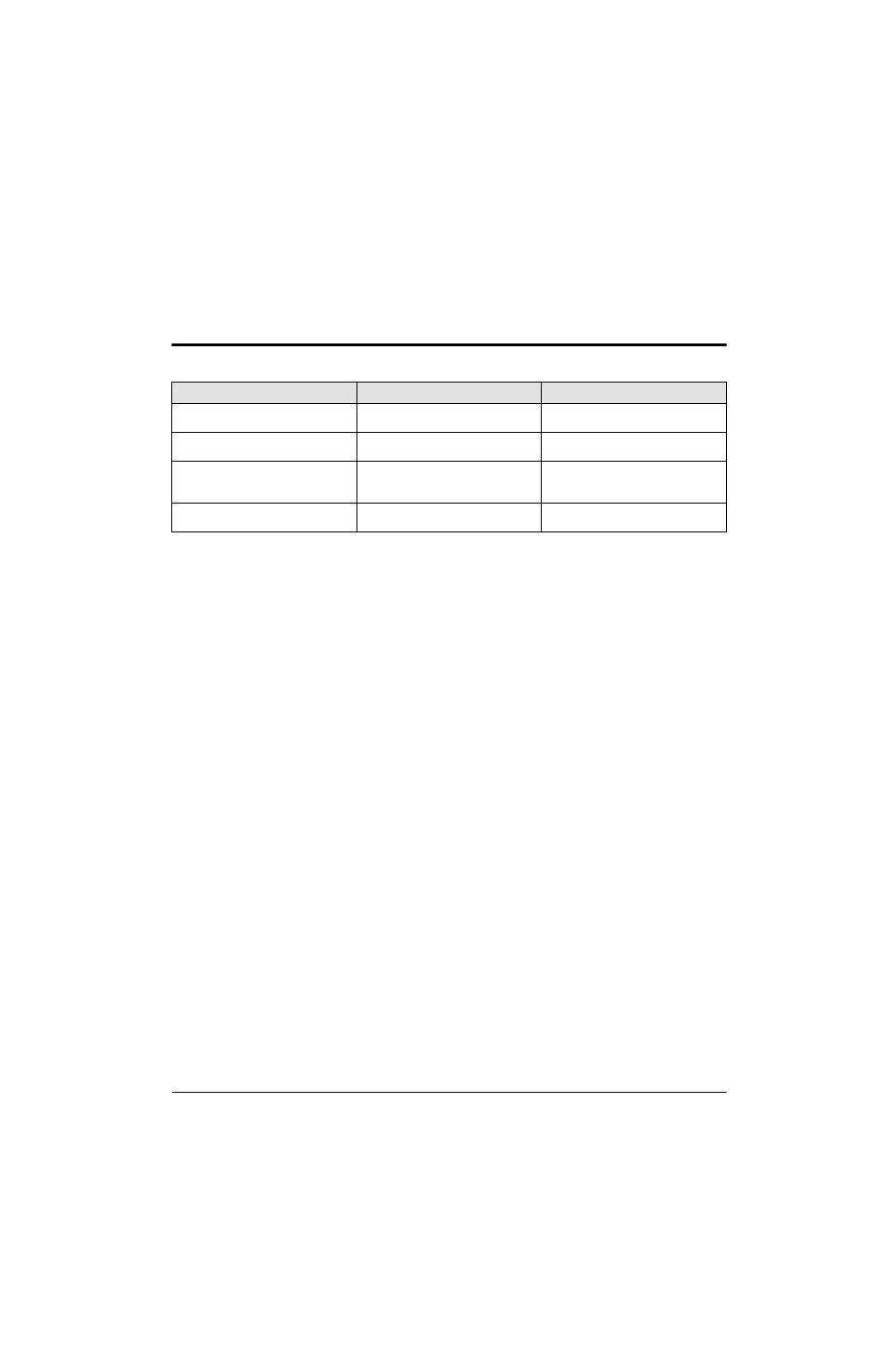

Symptom

Problem

Remedy

Customers electronic standard display

slowly decreases over time

Leak in system

Check all compression and pipe fittings

with soap solution

Electronic standard display does not

respond when Vernier knob is turned

No

Vernier

control

Readjust isolation valves on Orion;

replace O-ring on Vernier piston

Electronic standard display increases or

decreases when

PRESSURE

or

VENT

valves are closed

No Pressure or Vent control

Replace valve seats or O-rings in valves;

check valve needles

Gas escapes when external supply

pressure is bled

N

2

cylinder will not remain charged

Remove inlet check valve; clean or

replace

Table 3-1. Source 3000 Troubleshooting