2 initial setup, 3 pressure measurement sequence, 2 initial setup 2.3 pressure measurement sequence – Condec Source 3000 User Manual

Page 8

4

Source 3000 Operation and Maintenance Manual

2.2

Initial Setup

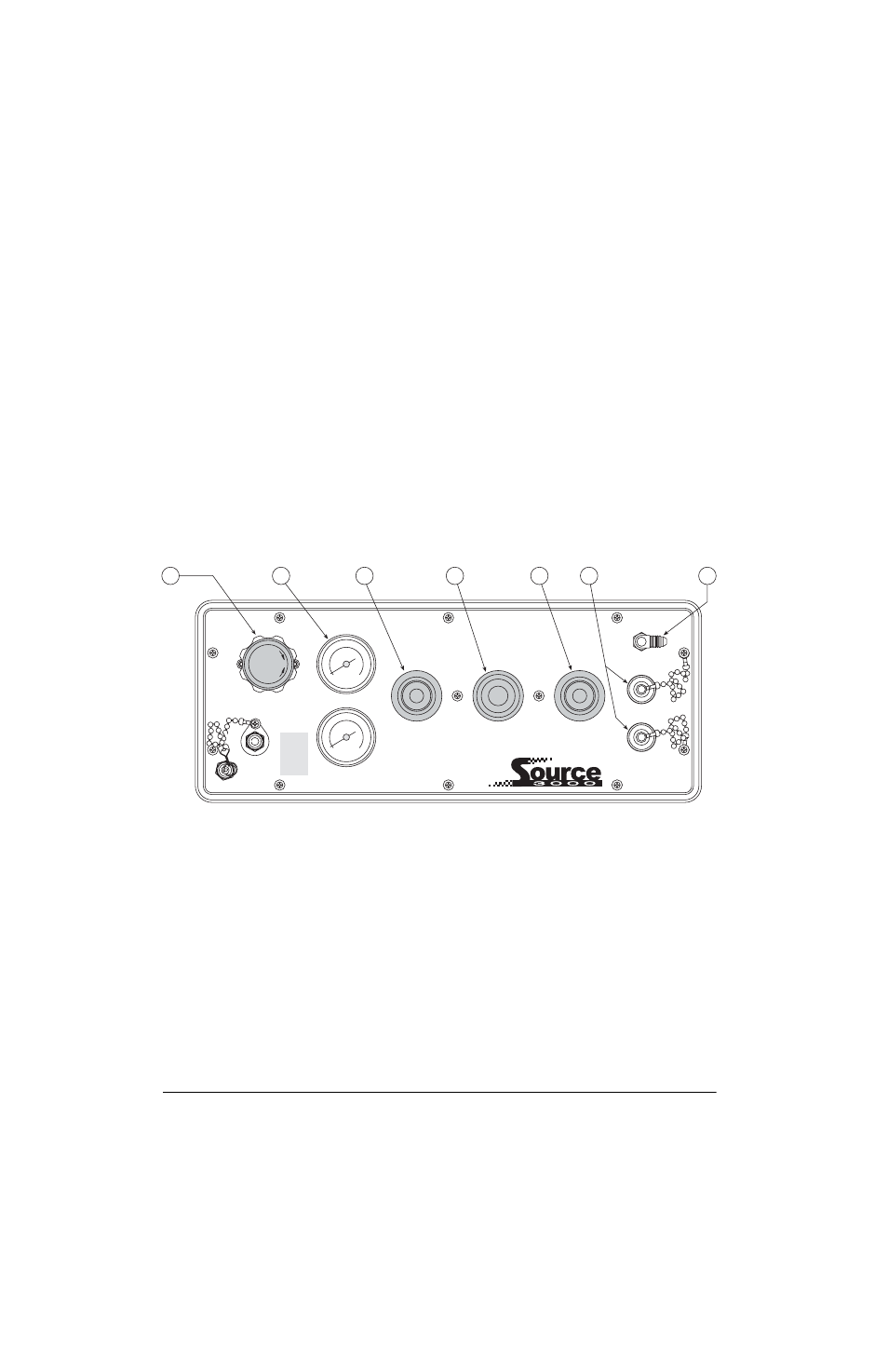

To prepare for actual calibration usage, see Figure 2-2 below and proceed as follows:

1. Check that the

COARSE ADJUSTMENT

valve (1) is closed (rotate clockwise until it stops) and that the

vent valve (2) is open (two turns counter-clockwise from its stop).

2. Using the

PRESSURE LIMIT CONTROL

regulator (5), adjust the maximum system input pressure, as read

by the pressure limit monitor (4), to any desired value higher (typically 20–50% higher) than the

full-scale range of the device under test. Using this technique, the device under test is fully protected

from being accidentally over-pressurized.

3. Connect the male quick disconnect end of the port hose supplied by customer to one of the port (6)

fittings. Use supplied 1/4 female NPT quick disconnect fitting, (PN 55394) between port hose and Port 1

or Port 2.

4. Connect the other end of the port hose to the input port of the electronic standard, using adapters if

required. Tighten all connections.

5. Connect the end of the test hose supplied by customer to the electronic standard output port and the other

end to the unit under test. Tighten all connections properly.

NOTE

: If using a tee type port/test hose

connection, the electronic standard is connected between the port and unit under test.

Figure 2-2. Initial Setup Procedure

2.3

Pressure Measurement Sequence

1. To apply pressure, close the

VENT

valve (2) approximately two turns until it stops, then open the

COARSE ADJUSTMENT

valve (1) approximately 1/2 turn counter-clockwise until the display begins to

move. The pressure may change rapidly until reaching approximately 90% of the desired final value.

2. Use either the

COARSE ADJUSTMENT

or

VENT

valve to obtain a specific pressure reading. Both provide

precise control. As the pressure approaches the desired value, the valve being used for control should be

rotated slowly clockwise to its closed position. With a little experience, pressure values very close to the

desired final value may be quickly achieved.

3. To obtain exact pressure readings, slowly rotate the

VERNIER

control (3) knob in the direction required

(clockwise to increase pressure) as indicated by the electronic standard display.

DECREASE

INCREASE

FILL PORT

MAX. 3000 PSI

NITROGEN ONLY

SUPPLY PRESSURE

PRESSURE LIMIT MONITOR

PRESSURE LIMIT CONTROL

COARSE ADJUSTMENT

VERNIER

VENT

VENT

PORT 2

PORT 1

6

7

2

3

1

4

5