Siting of the pump, General, Float switch operation – Stuart Turner Submersible Diver 35 & 45 User Manual

Page 6

- 6 -

SITING OF THE PUMP

WARNINGS:

Do not run against a closed valve for periods longer than 5 minutes.

The water in and around the pump must not be allowed to freeze. This

will result in pump damage.

Do not under any circumstances use the supply cord fitted, as a

means to carry or lower the pump into position on installation. Attach

a rope sling to handle.

Do not allow plastic pump parts to come into contact with solder flux,

oil or cellulose based paints, paint thinners or strippers, acid based

descalents or aggressive cleaning agents.

Never run pump whilst sucking air only as the motor will overheat.

To prevent this happening always install pump in the vertical position

and ensure fully submerged.

When siting the pump ensure its base is raised slightly from the

bottom of the sump reducing the possibility of blocking the filter with

debris or drawing in small stones.

General

If the pump is to be run continuously it must be installed in a vertical position and must

be submerged at all times to avoid overheating of the motor.

If the float switch is in use to empty a tank the pump may be operated partially

submerged for short periods (see float switch operation section for further details).

The pumps should be positioned away from pond plants (if applicable) to maximise flow

and prevent entanglement.

Float Switch Operation

All Diver models are fitted with a float switch for automatic operation.

The following guide will help you get the most out of your pump.

The pump must never run dry, needing a minimum water depth of 300 mm at all times.

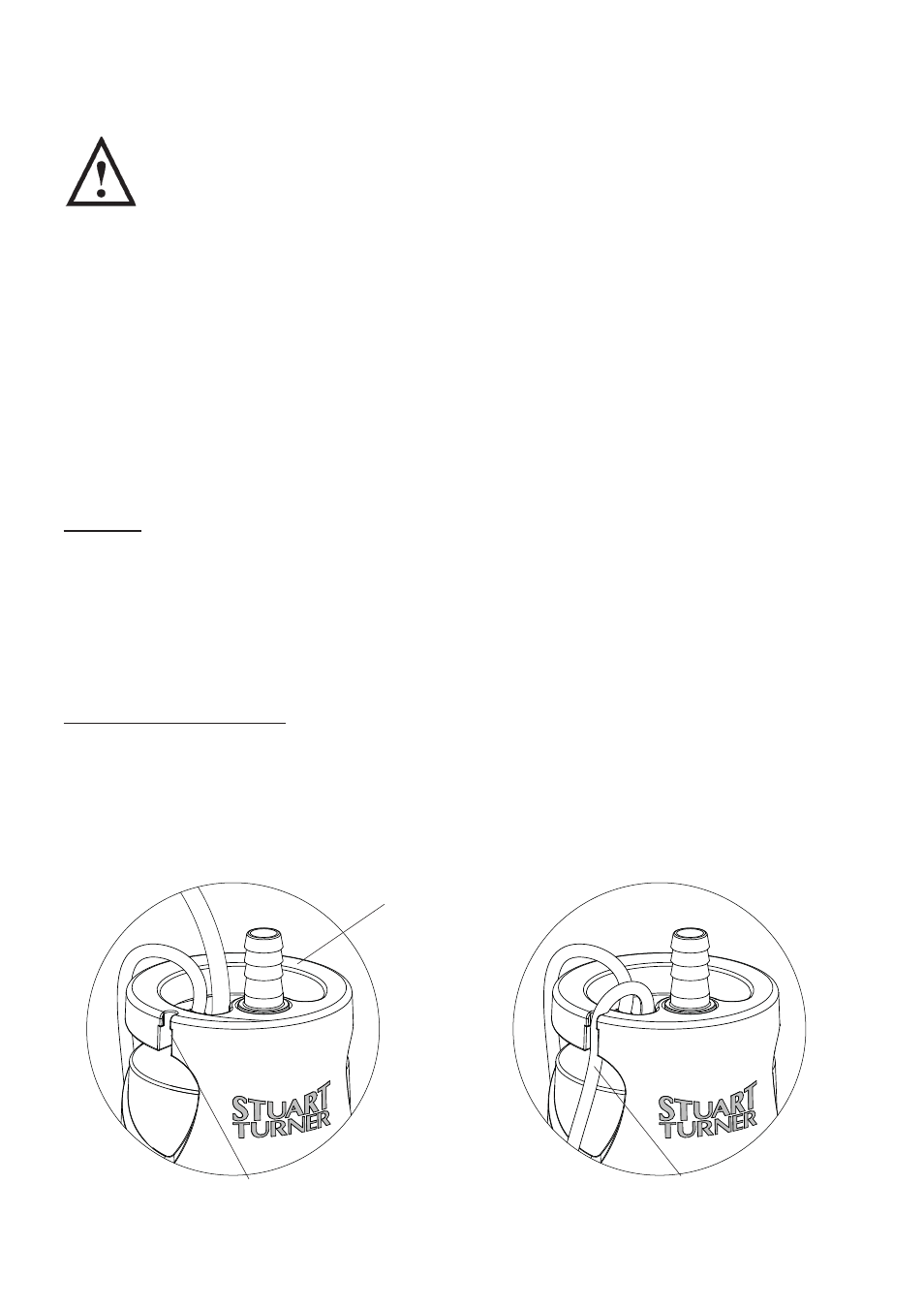

Adjustment of the float switch is achieved by lengthening or shortening the cable through

the moulded cable retention slot, which is located in the pump handle (Figs 4 and 5).

Note: When inserting cable into slot ensure it is fully engaged.

Fig. 4

Moulded cable

retention slot

Float Switch cable shown

slotted into position

Pump Handle

Fig. 5