Venting – Sterling RT User Manual

Page 9

– 9 –

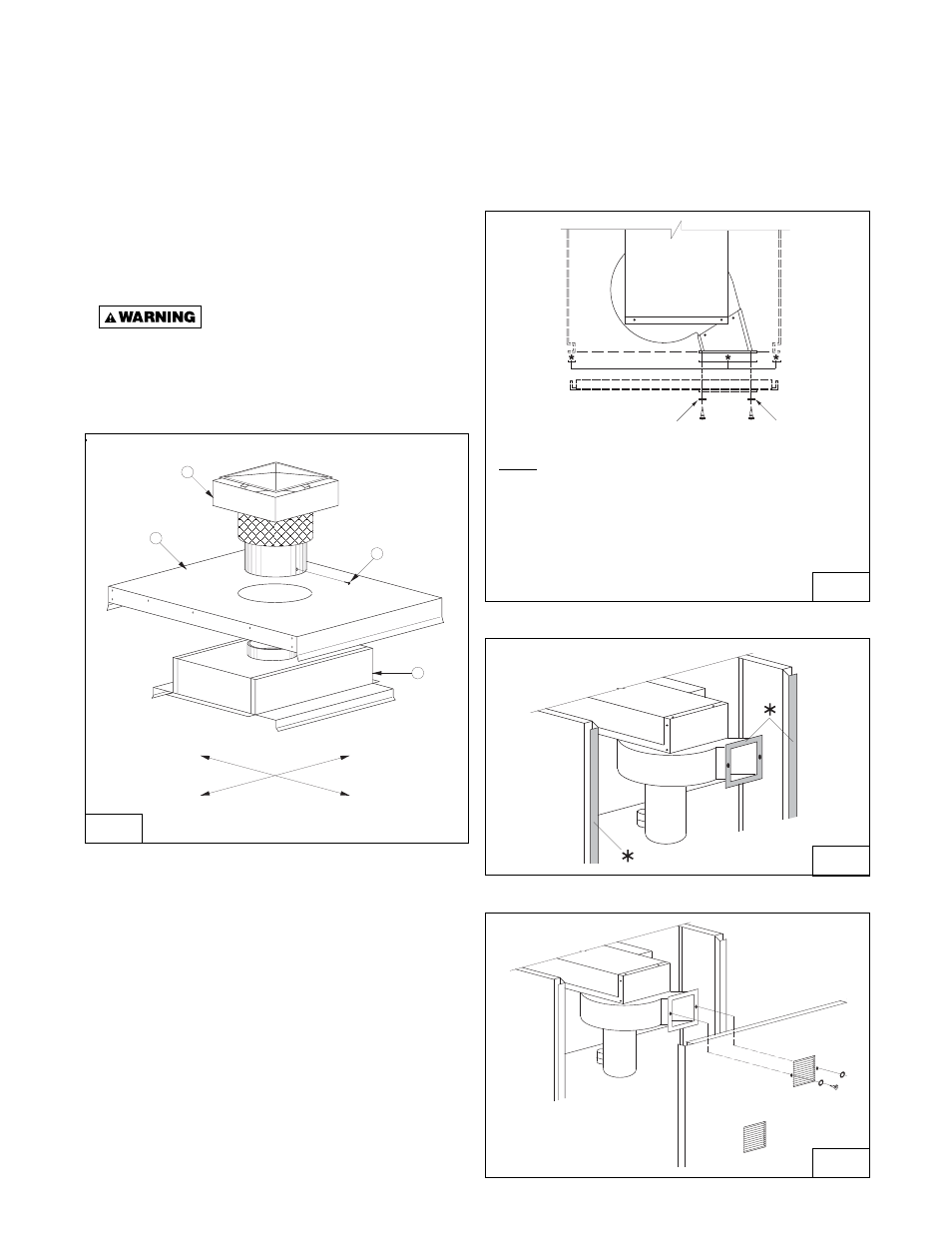

*These Surfaces (indicated with an asterisk in fi gures 8a & 8b)

MUST be flush and sealed at all times to ensure the proper

discharge of fl ue products from the unit.

These discharge fl anges are equipped with special gasketing,

which must create an air tight seal connection around the

louvers of the access panel.

Secure in place the access door to the discharge adaptor using

the two screws and neoprene washers, then tighten

the grip latches (see service access panel removal

section).

Power vented models are designed with combustion

air inlet and fl ue products outlet located in the louvered

side access panel. Never locate these units in an

area where the flue products outlet may be directed

at any fresh air vents.See Figures 8a 8b, and 8c for

installation and servicing requirements.

Figure 8a - Power Venter Discharge Location

Figure 8b

Figure 8c

VENTING

All venting installations shall be in accordance with the

latest edition of “Part 7, Venting of Equipment of the

National Fuel Gas Code, ANSI Z223.1 (NFPA 54), or

applicable provisions of local building codes”.

Natural venting models are equipped with a vent cap

designed for natural venting. Air for combustion enters

at the base of the vent through a protective grille, and

the design of the vent cap is such that the products of

combustion are discharged at the upper section of the

cap. The cap is shipped in a separate carton. It should

be fastened in position as shown in Figure 7 and

should not be altered in any way.

The venting is an integral part of

the unit and must not be altered in the field. If

altered, excessive carbon monoxide could be

produced.

Figure 7 - Vent Cap Assembly

(Natural Vented Furnaces Only)

FIELD INSTALLATION INSTRUCTIONS

1. Remove “Side Access Panel”.

2. Insert Vent Sleeve of “Vent Cap Assembly” (Item 1)

thru “Top Panel Assembly” (Item 2), and over Vent

Collar of “Flue Collector Assembly” (Item 3).

3. Align “Vent Cap Assembly” so it is square to “Top

Panel Assembly”.

4. Fasten with “Drill Screw” or “Sheet Metal Screw” (Item

4) by reaching between “Flue Collector Assembly”

(Item 3) & “Top Panel Assembly” (Item 2), and drilling

through vent sleeve of “Vent Cap Assembly” into vent

collar of “Flue Collector Assembly”.

5. Replace “Side Access Panel”.

NOTICE: If your unit is to be equipped with the

optional extended vent cap assembly, see the

special instructions supplied with the vent cap.

D3591

2

1

4

3

FRONT

REAR

LEFT

RIGHT

D3591

D4596

TOP VIEW

Neoprene Washers

Screws

D3725

D3505