Lighting, Chart 5 - main burner orifi ce schedule – Sterling RT User Manual

Page 17

– 17 –

93

42

116

42

140

42

163

42

186

42

210

42

233

42

280

42

302

43

326

42

372

42

40

54

50

54

60

54

70

54

80

54

90

54

100

54

120

54

130

55

140

54

160

54

93

42

116

42

140

42

163

42

186

42

210

42

233

42

280

42

280

42

326

42

326

42

372

42

LIGHTING

Purge the gas line of air before attempting to light the

pilot in the unit. Wait 5 minutes for unburned gas to

vent. Check for gas leaks.

Never use an open flame to

detect gas leaks. Explosive conditions may

exist which could result in personal injury or

death.

The unit is furnished with an intermittent pilot ignition

system. A lighting instruction plate is permanently

attached to the unit for the pilot system supplied with

the unit. To set the intermittent pilot ignition system

in operation, proceed as follows:

1. Turn on the main manual valve and pilot valve.

2. Turn on electrical power. The unit should now be

under the control of the thermostat.

3. Turn the thermostat to the high heat reading to see

if the pilot and main burner ignite.

4. Tur n the ther mostat to the lowest setting to

interrupt power to the ignition system to determine

that both the pilot burner and main burner are

extinguished.

5. Set the thermostat at the desired setting for normal

operation.

For complete shutdown:

1. Tur n the main and pilot valves to the OFF

position.

2. Shut off electric power.

3. Adjust the thermostat to the lowest setting.

*

INPUT

IN

1000

BTU

2500 BTU/Ft

3

(93.1 MJ/m

3

)

PROPANE

TYPE OF GAS

NATURAL

HEATING VALUE

1075 BTU/Ft

3

(40.1 MJ/m

3

)

3.5 inch WC

(0.87kPA)

10 inch WC

(2.49 kPA)

NUMBER

OF

BURNER

ORIFICES

MANIFOLD

PRESSURE

40

54

50

54

60

54

70

54

80

54

90

54

100

54

120

54

120

54

140

54

140

54

160

54

PV/RT

100

PV/RT

125

PV/RT

150

PV/RT

175

PV/RT

200

PV/RT

225

PV/RT

250

PV

300

RT

300

PV

350

RT

350

PV/RT

400

4

5

6

7

8

9

10

12

12

14

14

16

FT

3

/HR

ORIFICE DRILL

FT

3

/HR

ORIFICE DRILL

FT

3

/HR

ORIFICE DRILL

FT

3

/HR

ORIFICE DRILL

FT

3

/HR

ORIFICE DRILL

FT

3

/HR

ORIFICE DRILL

FT

3

/HR

ORIFICE DRILL

FT

3

/HR

ORIFICE DRILL

FT

3

/HR

ORIFICE DRILL

FT

3

/HR

ORIFICE DRILL

FT

3

/HR

ORIFICE DRILL

FT

3

/HR

ORIFICE DRILL

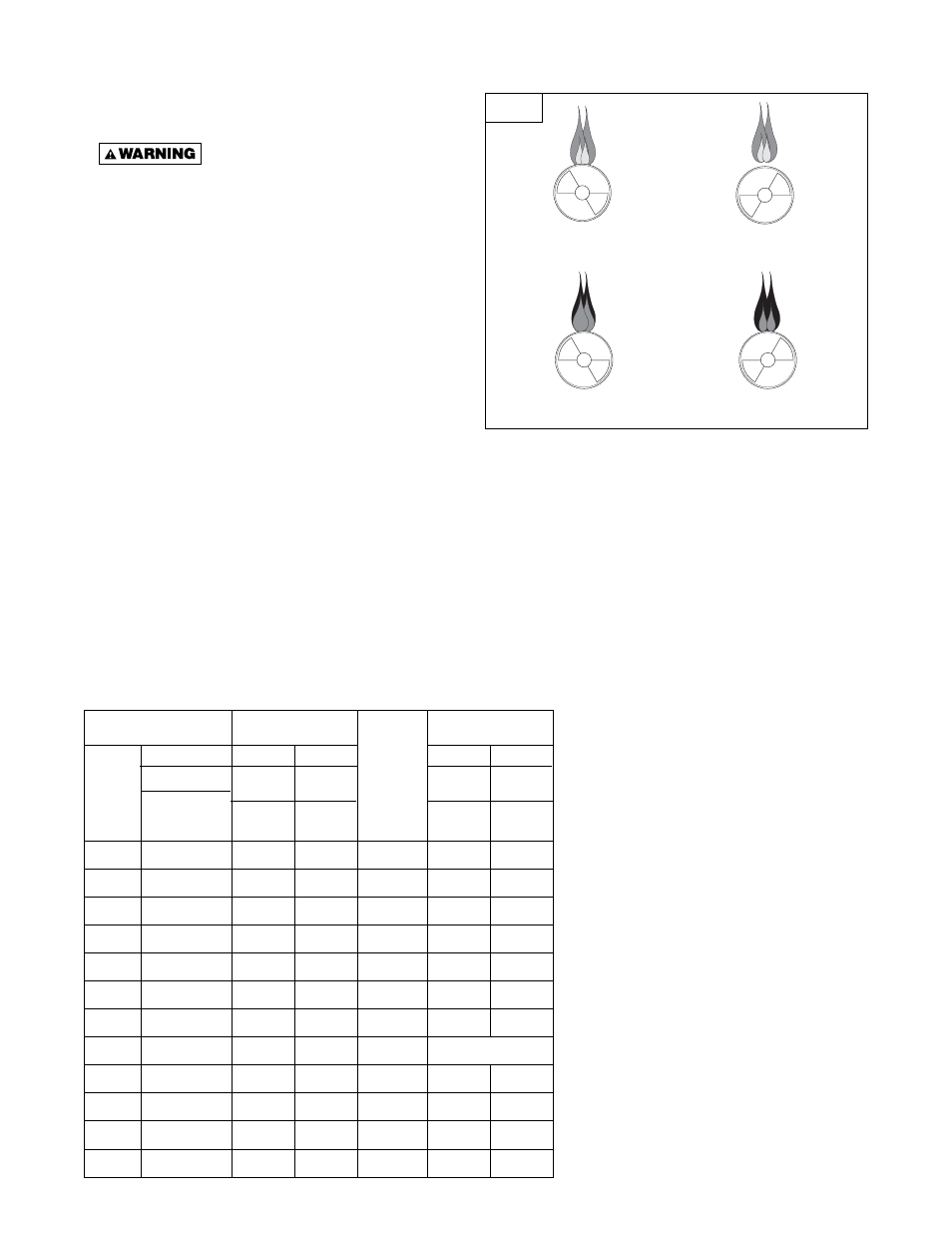

Figure 12 - Main Burner Flames

NOTICE: There may be momentary and spasmodic

orange flashes in the flame. This is caused by the

burning of airborne dust particles, and not to be

confused with the yellow tipping, which is a stable

or permanent situation when there is insufficient

primary air.

D3652

NORMAL

(HARD FLAME)

YELLOW TIPPING

(MARGINAL)

YELLOW FLAME

(TOO LITTLE AIR)

LIFTING

(TOO MUCH AIR)

2500 BTU/Ft

3

(93.1 MJ/m

3

)

PROPANE

NATURAL

1075 BTU/Ft

3

(40.1 MJ/m

3

)

3.5 inch WC

(0.87kPA)

10 inch WC

(2.49 kPA)

HIGH TEMP. RISE

FURNACE (30°-90°F)

STD. TEMP. RISE

FURNACE (20°-60°F)

Chart 5 - Main Burner Orifi ce Schedule*

* This schedule is for units operating within the U.S.A.

at normal altitudes of 2000 ft. (610m) or less. For

altitudes above 2,000 ft., refer to local codes, or in

absence of local codes, refer to the latest edition of

the National Fuel Gas Code ANSI Standard Z223.1

(NFPA no. 54).

When installed in Canada, any references to deration

at altitudes in excess of 2000 feet (610m) are to be

ignored. At altitudes of 2000 to 4500 feet (610 to

1372m), the unit heaters must be orifi ced to 90% of the

normal altitude rating, and be so marked in accordance

with the ETL certifi cation.

NOT AVAILABLE