Sterling RT User Manual

Page 24

– 24 –

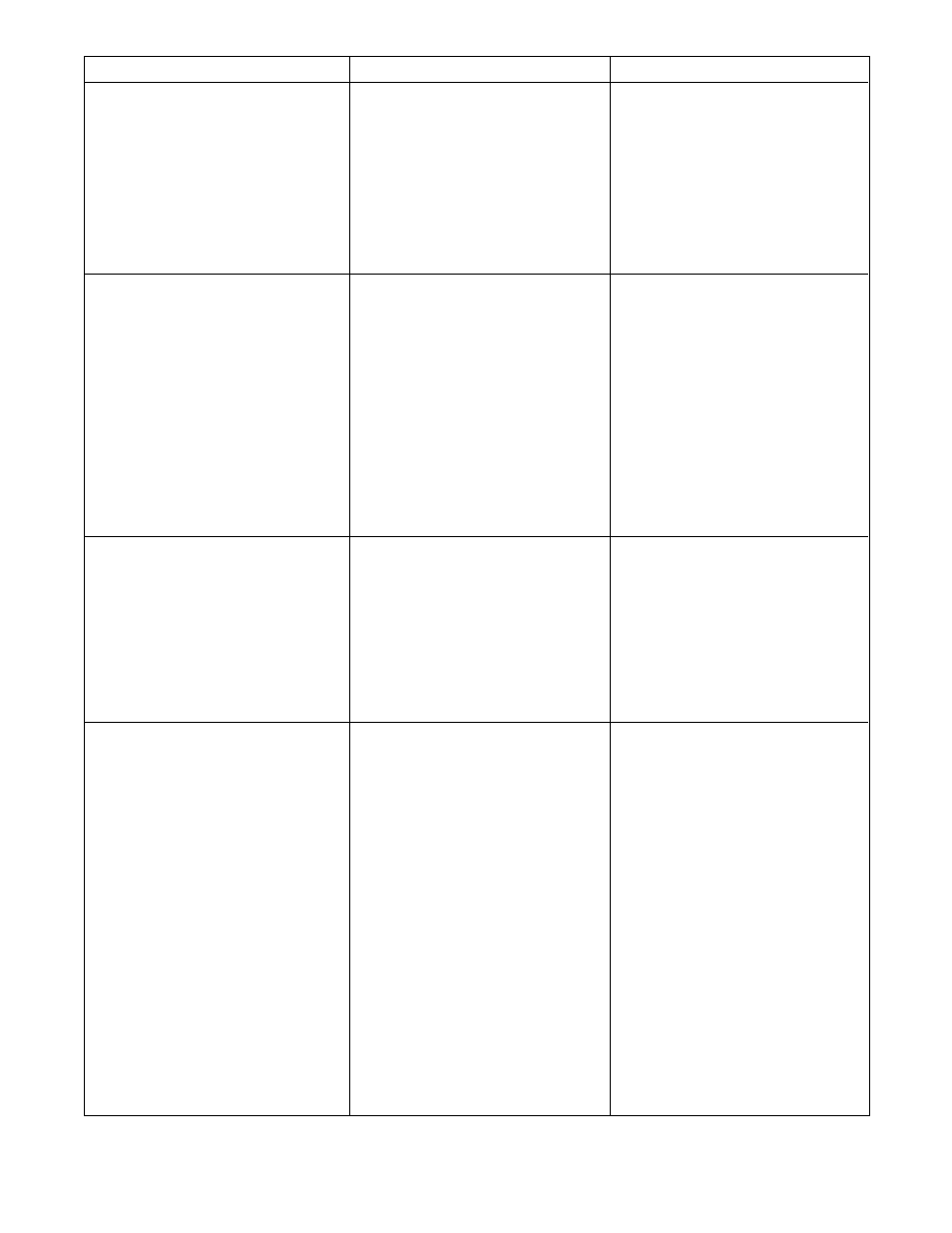

Chart 6 - Troubleshooting continued

SYMPTOMS

J. Floating fl ame.

K. Burner won't turn off.

L. Rapid burner cycling.

M. Not enough heat.

POSSIBLE CAUSES

1. Blocked heat exchanger.

2. Insuffi cient combustion air.

3. Blocked venting.

4. Air leak into combined

chamber, draft hood, or fl ue

collector.

1. Poor thermostat location.

2. Defective thermostat.

3. Improper thermostat or

transformer.

4. Short circuit.

5. Defective or sticking gas valve.

6. Excessive gas supply

pressure.

1. Loose electrical connections at

gas valve or thermostat.

2. Excessive thermostat heat

anticipation.

3. Unit cycling on high limit.

4. Poor thermostat location.

1. Incorrect gas input.

2. Heater undersized.

3. Thermostat malfuction.

4. Heater cycling on limit control.

5. Check outside dampers if

used.

CORRECTIVE ACTION

1. Clean heat exchanger.

2. Clean combustion air inlet

openings in bottom panel.

Refer to installation.

3. Clean fl ue. Refer to

installation.

4. Determine cause and repair

accordingly. Refer to

installation.

1. Relocate thermostat away

from

drafts.

2. Replace thermostat.

3. Check wiring diagrams.

4. Check operation at valve.

Look for short and correct

(such as staples piercing

thermostat

wiring).

5. Replace gas valve.

6. Refer to operation.

1. Tighten all electrical

connections.

2. Adjust thermostat heat

anticipation for longer cycles.

Refer to operation.

3. Check for proper air supply

across heat exchanger.

4. Relocate thermostat. (Do not

mount thermostat on unit).

1. Refer to operation.

2. This is especially true when

the heated space is enlarged.

Have the heat loss calculated

and compare to the heater

output (80% of input). Your

gas supplier or installer can

furnish this information. If

heater is undersized, add

additional heaters.

3. Replace thermostat.

4. Check air movement through

heat exchanger. Check

voltage to power venter motor,

clean power venter wheel and

heat exchanger, and oil power

venter motor. Check fi lters,

replace if necessary.

5. Adjust dampers accordingly.