Sterling SF User Manual

Page 24

24

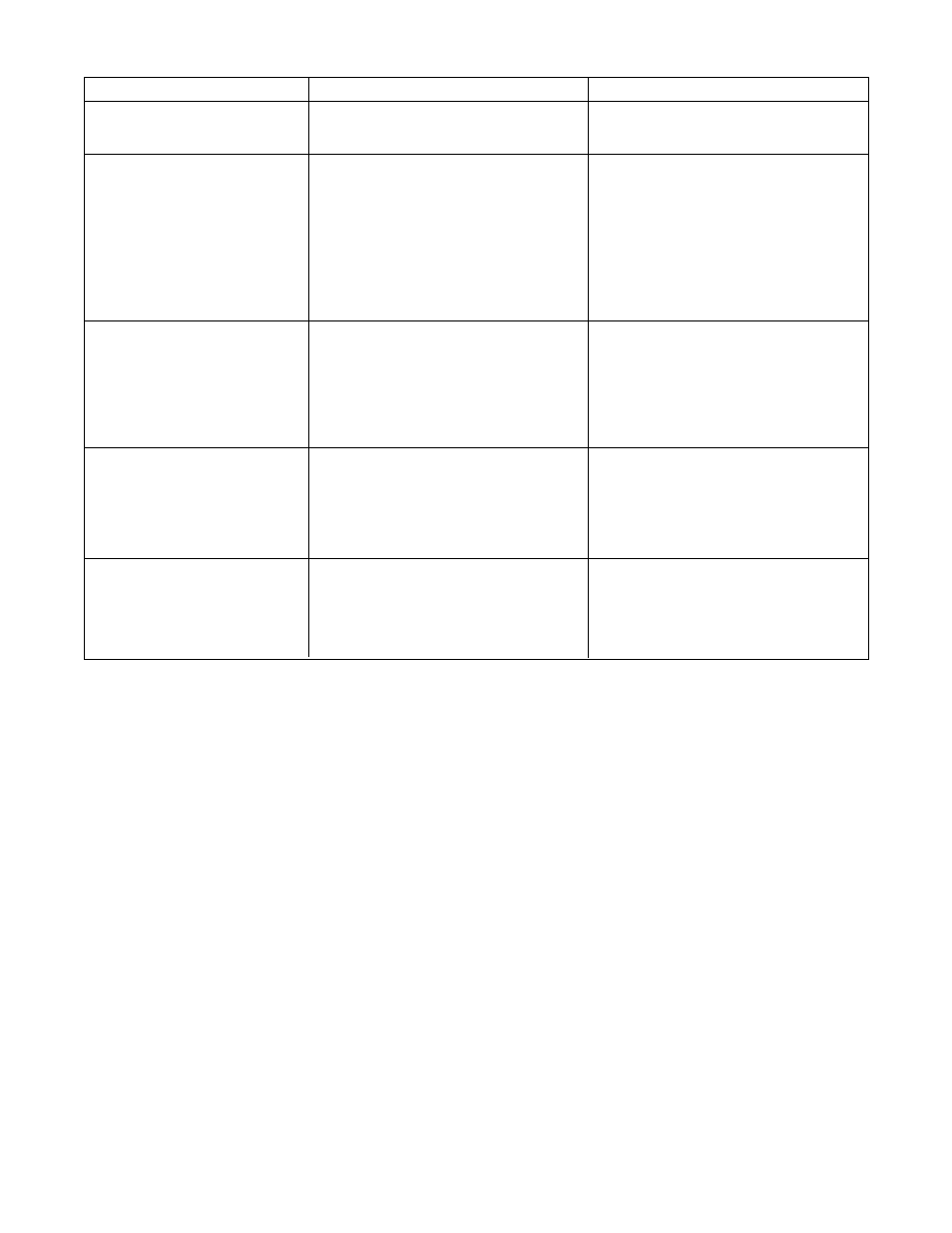

Q. Cold air is delivered during

heater operation.

R. High limit tripping.

S. Power ventor will not run.

T. Power ventor turns on and off

during operation.

U. Power ventor will not stop.

1. Refer to “Gas Piping Requirements”, test and

reset manifold pressure.

2.

Refer

to

“Operation”.

1. Burner orifi ces may be too large, verify

and replace. Refer to “Gas Input Rate”.

2. Check for proper voltage, ensure fan

blade is correct.

3. Check operation of switch. If switch is open

during operation, check gas pressure; adjust

accordingly. If switch is open during start-up,

replace switch.

4. Check for 24V on line side of the high limit.

Constant voltage should be recorded. If not

control board is suspect. Check fl ash code.

1.

Check all wring in the power vent circuit to

ensure good connection, including “Neutral”.

2. Check for 115V between motor leads and

check amp draw of motor. Replace if needed.

3. Check for continuous 115V on terminal

“CBM Blower” and neutral during call for

heat. If not present and all checks are

normal, replace.

1. Check power ventor circuit per wiring

diagram.

2.

Check motor voltage and amp draw to motor

name plate, replace if motor found defective.

3. Check for continuous 115V on terminal

“CMB Blower” during call for heat, replace

board if found defective.

1. Check power ventor circuit per wiring

diagram.

2.

Heater is in lockout mode check fl ash code

table for problem.

3. No fl ash codes present along with no call

for heat, replace control board.

SYMPTOMS

POSSIBLE CAUSE(S)

CORRECTIVE ACTION

1. Incorrect manifold pressure or input.

2. Air throughput too high.

1. Unit is over fi red.

2. Air fl ow is low.

3.

Defective

switch.

4. Defective control board.

1. Loose wiring or connections.

2. Motor overload is tripped or bad motor.

3. Defective control board.

1. Power ventor improperly wired.

2. Motor overload cycling or defective motor.

3. Defective control board.

1. Power ventor improperly wired.

2. Main burner did not light on call for heat.

3. Defective control board.

Table 7 - Separated Combustion Tubular Propeller Troubleshooting Guide