Horizontally vented unit heaters (category iii), Venting (continued) – Sterling TC User Manual

Page 18

18

HORIZONTALLY VENTED UNIT HEATERS

(CATEGORY III)

Horizontal venting arrangements are designed to be used

with single wall vent pipe. Horizontal venting arrangements

must terminate external to the building using UL 1738

Listed single wall or double wall vent. For installations in

Canada, use corrosion resistant and gas-tight, listed vent

pipe conforming with local building codes, or in the absence

of local building codes, with current CSA-B149.1, Installation

Codes for Natural Gas Burning Appliances and Equipment

or CSA-B149.2, Installation Codes for Propane Gas

Burning Appliances and Equipment. See Figures 8, 9A and

10A for special installation requirements regarding these

venting conditions.

Do not use Type B (double wall)

vent internally within the building on horizontally

vented power vented units! This can result in

death, serious injury or substantial property

damage.

If double wall venting is used, components which are UL

Listed and approved for Category III positive pressure

venting systems MUST be used.

A Breidert Type L, Fields Starkap, or equivalent vent cap

must be supplied by the customer for each power vented

unit. The vent pipe diameter MUST be as specified in

Table 1. All unit sizes are factory equipped with the

required fl ue size collar; attach in place (if not mounted

to outlet); refer to included vent collar instruction sheet

for additional requirements.

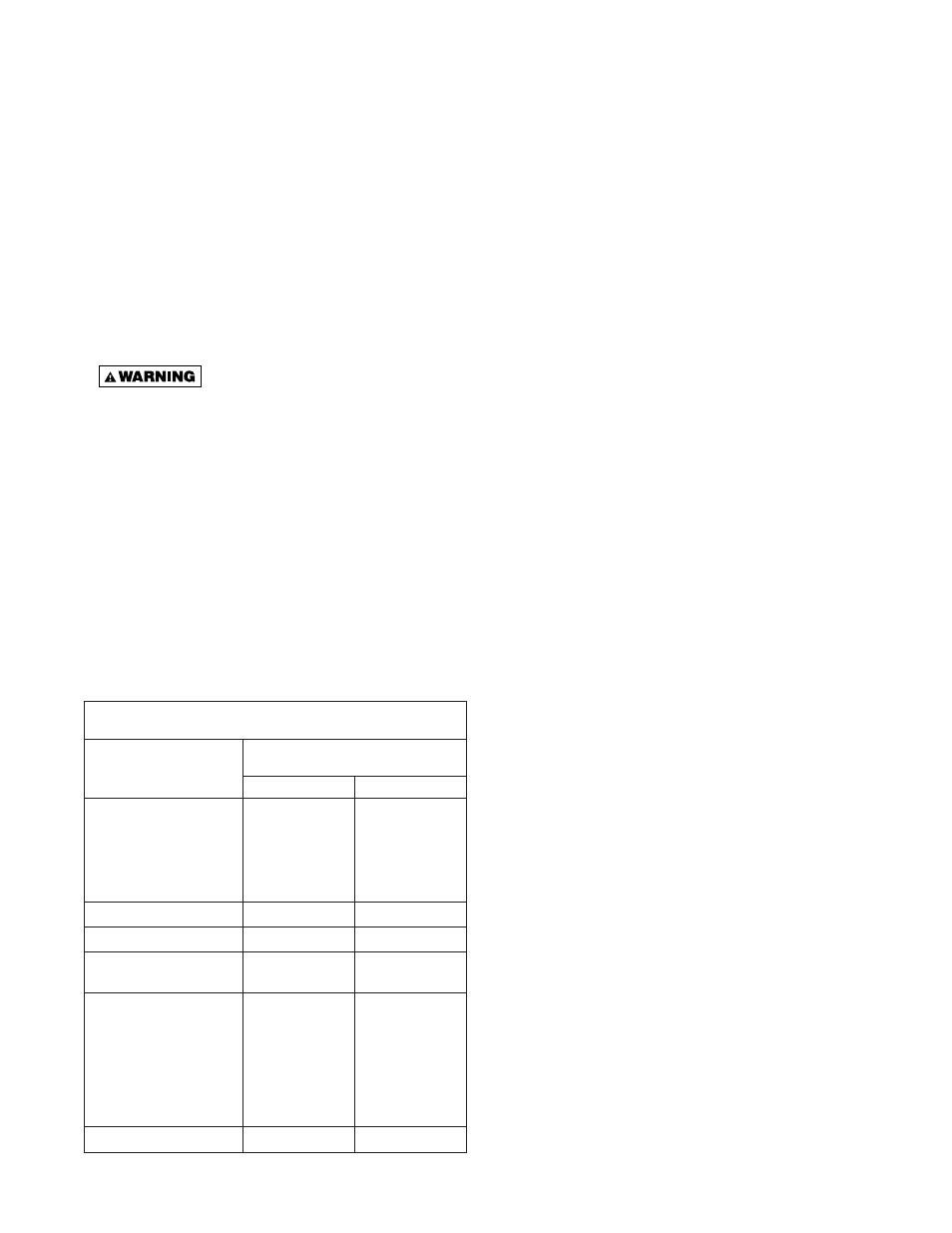

Table 7

The vent terminal must be at least 12" (305mm) from

the exterior of the wall that it passes through to prevent

degradation of the building material by fl ue gases.

Through the wall vent for these appliances shall NOT

terminate over public walkways, or over an area where

the condensate or vapor could create a nuisance or

hazard or could be detrimental to the operation of

regulators, relief valves, or other equipment.

The vent pipe equivalent length must not exceed 50'

(15.2m). Equivalent length is the total length of straight

sections PLUS 10' (3.05m) for each 90° elbow and

4' (1.22m) for each 45° elbow.

Maintain clearance between the vent pipe and com-

bustible materials according to vent pipe manufacturers

instructions

Seal all vent pipe joints and seams to prevent leakage.

Use General Electric RTV-108, Dow-Corning RTV-732

silicone sealant or equivalent sealant with a temperature

rating of 500° F; or 3M #425 aluminum foil tape (or

equivalent). The vent air system must be installed to

prevent collection of condensate. Pitch horizontal pipes

downward 1/4" per foot (21mm per meter) toward the

outlet for condensate drainage.

Horizontal portions of the venting systems shall be

supported at maximum intervals of 4' (1.2m) to prevent

sagging (in Canada, suppor t at 3' (1m) maximum

intervals).

Insulate single wall vent pipe exposed to cold air or

running through unheated areas.

Each unit must have an individual vent pipe and vent

terminal! Each unit MUST NOT be connected to other

vent systems or to a chimney.

VENTING (continued)

Vent Systems

Termination Clearance Requirements

Structure/Object

Minimum Clearance

for Termination Locations

USA

CANADA

Door, window, or gravity vent

inlet; combustion air inlet for

other appliances

9 inch for 10,000 to

50,000 BTU/Hr

input; 12 inch for

input exceeding

50,000 BTU/Hr.

9 inch (230mm) for

10,000 to 50,000

BTU/Hr input;

12 inch (305mm)

for input exceeding

50,000 BTU/Hr.

Forced air inlet within 10 feet

3 feet above

6 feet (1.8m)

Adjoining Building or parapet

6 feet

6 feet (1.8m)

Adjacent public walkways

7 feet above

grade

7 feet (2.1m) above

grade

Electric, gas meters

& regulators

4 feet horizontal

3 feet (0.9m)

horizontally from

meter/regulator

asembly. 6 feet

(1.8m), any

direction, from

a gas service

regulator vent outlet

Above grade level*

1 foot*

1 foot (0.3m)*

*Above maximum anticipated snow depth.