7 model code – Yokogawa SC24V Differential pH ORP Electrode User Manual

Page 16

IM 12B6J7-02E-E

16

6.3 Maintenance of the SC24V sensor

A pH sensor requires routine maintenance

to keep the measuring elements clean and

functioning. Because the SC24V sensor does

not have an open reference junction and is

hermetically sealed from the process, it does

not suffer from poisoning, diffusion and fouling.

This means the SC24V sensor requires very little

maintenance.

In most cases cleaning with water, iso-propanol

or methanol is sufficient. In other cases the

measuring elements of the sensor have to be

cleaned with specific solutions. Examples:

1. Deposits of limes, hydroxides or carbonates

can be removed by immersing the bottom

part of the sensor in a solution containing

dilute hydrochloric acid (5% is recommended).

Afterwards rinse the sensor with water.

2. Deposits of oil and fat can be removed with

hot water with a detergent. When the results

are unsatisfactory, a mild (carbonate based)

abrasive can be used.

3. Protein deposits should be removed with

a protein enzymatic solution, for instance

a solution containing 8.5 ml concentrated

hydrochloric acid and 10 grams of pepsin in

1 liter of water.

A soft toothbrush may be used to accelerate the

cleaning process.

Note: Avoid cleaning with non-polar solvent like

tri-chloro ethylene, toluene or hexane.

The non-polar solvents will break up the

gel-layer on the measuring glass elements

and requires that the sensor has to be

soaked in water for at least

12 hours before it will function again.

7 MODEL CODE

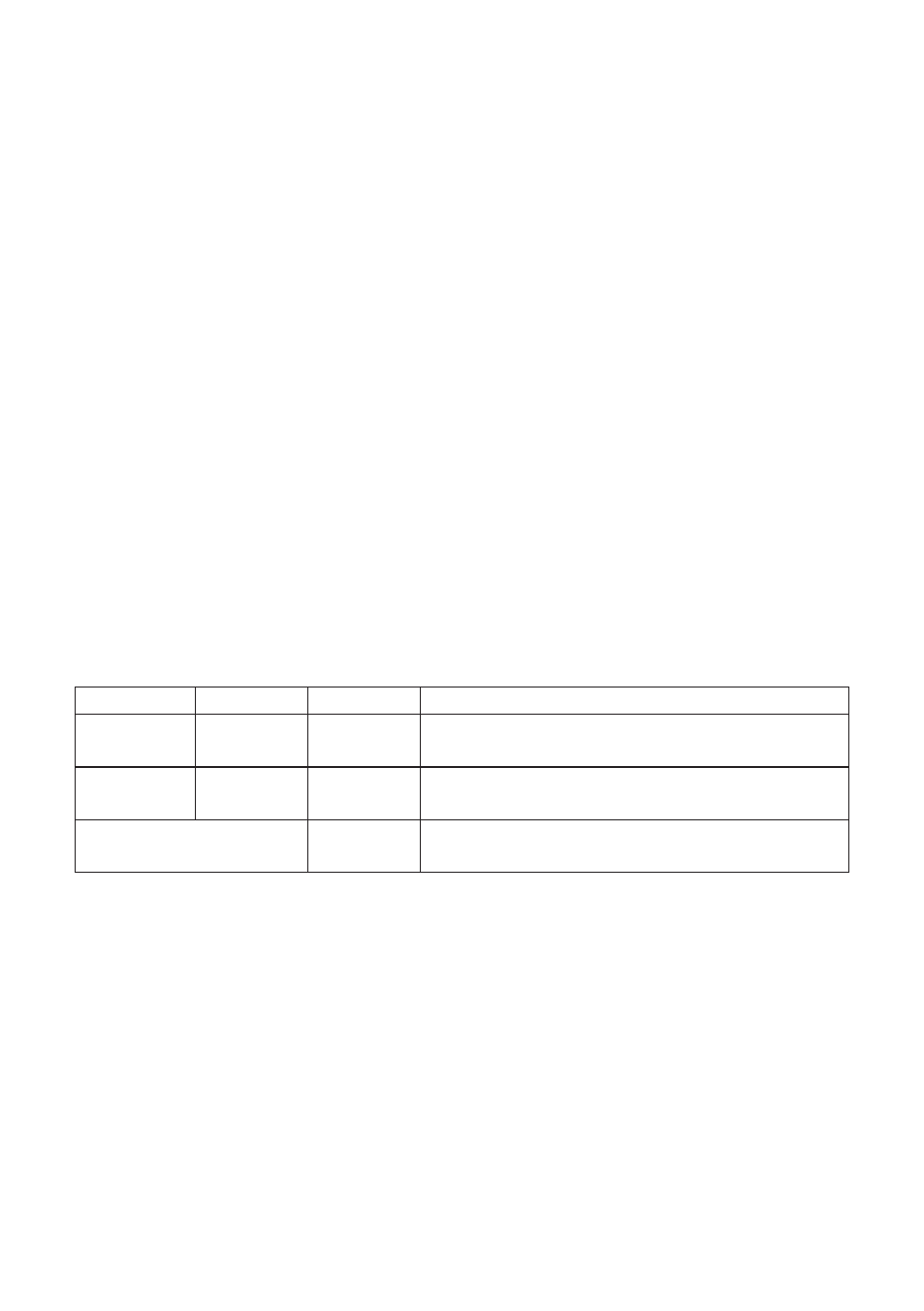

Model Code Suffix Code Option Code Description

SC24V

Combined 12mm 4 in 1 differential pH sensor

with Variopin connector

Type

- ALN26

Ag/AgCl reference system, pH half cell L-glass,

reference cell salt sensitive glass, non-flow, heavy duty

Sensor length

- 120

120 mm

- 225

225 mm

Sensor is standard equipped with a slide ring (Ryton) and an O-ring (Silicon) for mounting in adapters

(see Section 3.3). These parts and other O-ring materials are available as a spare part.