Optional specifications (others) – Yokogawa EJX438B User Manual

Page 98

<10. General Specifications>

10-12

IM 01C27H01-01E

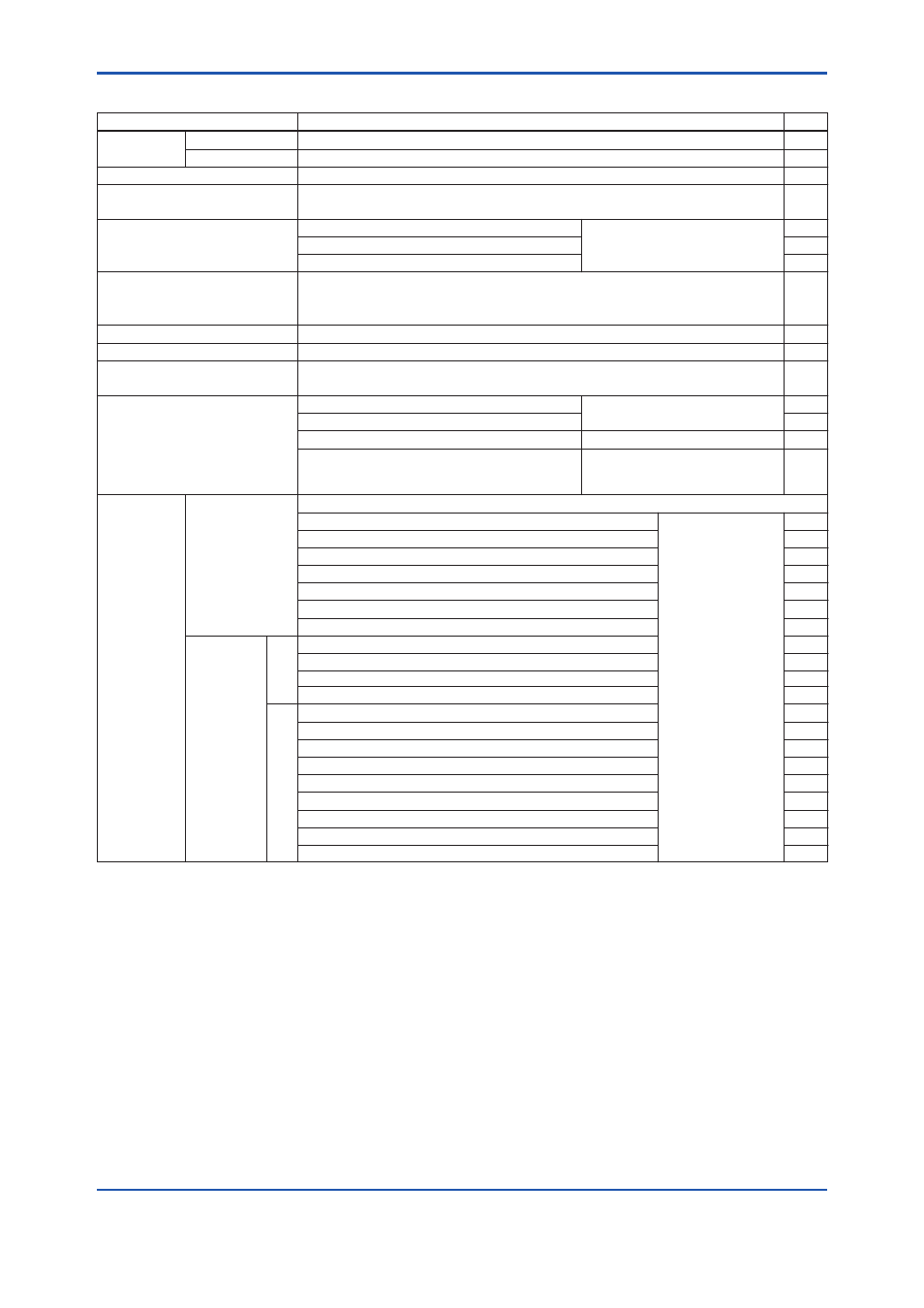

OPTIONAL SPECIFICATIONS (Others)

T14E.ai

Code

Description

Item

K1

Degrease cleansing treatment

Oil-prohibited use

D1

P calibration (psi unit)

Calibration units

*3

D3

bar calibration (bar unit)

(See table for Span and

Range Limits.)

D4

M calibration (kgf/cm

2

unit)

TF1

Diaphragm protection from sticky process fluid by FEP Teflon film attached with

fluorinated oil.

Operation range: 20 to 150°C, 0 to 2 MPa (Not applicable for vacuum service).

Teflon film

*2 *7

R

Adjusting range : 80°C to Maximum temperature of specified fill fluid

Operating temperature correction

*4

V

When ambient temperature exceeds 100°C, or use of PVC is prohibited

Capillary without PVC sheaths

A1

Inside of isolating diaphragms (fill fluid side) are gold plated, effective for hydrogen

permeation.

Gold-plated diaphragm

*5

M2W

Process flange, Block

Material certificate

M5W

Process flange, Block, Ring

*6

M2E

Process flange, Block, Pipe, Base

For Flush type

M2Y

High Pressure side: Process flange, Block, Pipe,

Base

*12

Low Pressure side: Process flange, Block

For Extended type

For Combination type

K5

Degrease cleansing treatment and dehydrating treatment

Oil-prohibited use

with dehydrating treatment

(Flange rating)

(Test pressure)

T51

JIS 10K

2 MPa (290 psi)

T54

T57

JIS 40K

*8

10 MPa (1450 psi)

T52

ANSI/JPI Class 150

3 MPa (430 psi)

T56

ANSI/JPI Class 300

*8

8 MPa (1160 psi)

T55

ANSI/JPI Class 300

*9

7 MPa (1000 psi)

T58

ANSI/JPI Class 600

*8

16 MPa (2300 psi)

Nitrogen (N

2

) Gas

*10

Retention time:

10 minutes

Pressure test/

Leak test

Certificate

*11

T51

JIS 10K

2 MPa (290 psi)

JIS 20K, 40K, 63K

3.5 MPa (500 psi)

T53

T53

ANSI/JPI Class 300, 600

3.5 MPa (500 psi)

T51

JIS 10K

2 MPa (290 psi)

T54

JIS 20K

5 MPa (720 psi)

T57

JIS 40K

*8

10 MPa (1450 psi)

T55

JIS 40K

*9

7 MPa (1000 psi)

T58

JIS 63K

*8

16 MPa (2300 psi)

T52

ANSI/JPI Class 150

3 MPa (435 psi)

T56

ANSI/JPI Class 300

*8

8 MPa (1160 psi)

T55

ANSI/JPI Class 300

*9

7 MPa (1000 psi)

T58

ANSI/JPI Class 600

*8

16 MPa (2300 psi)

EJX118B

Fo

r

A-

Ca

ps

ule

EJX438B

For B-Capsule

JIS 20K

5 MPa (720 psi)

Painting

Color change

Coating change

Amplifier cover only

Anti-corrosion coating *

1

P

X2

ANSI/JPI Class 150

3 MPa (430 psi)

T52

*1:

Not applicable with color change option.

*2:

Applicable for flush type (process connection style code W.)

*3:

The unit of MWP (Max. working pressure) on the name plate of a housing is the same unit as specified by option code D1, D3, and

D4.

*4:

Specify the process operating temperature for zero correction. Example: Zero correction by process temperature 90°C.

*5:

Applicable for wetted parts material code SW, SE, SY, and HW.

*6:

Applicable for flushing connection ring code 1, 2, 3, 4, A, B, C, and D.

*7:

Applicable for flushing connection ring code 0.

*8:

Applicable for flush type (process connection style code W.)

*9:

Applicable for extended type and Combination type (process connection style code E and Y.)

*10: Pure nitrogen gas is used for oil-prohibited use (option code K1 and K5.)

*11: The unit on the certificate is always MPa regardless of selection of option code D1, D3, or D4. A flushing connection ring will not be

applied when conducting the pressure test or leak test.

*12: Applicable for model EJX118B.