Ratio – Watlow Series 988 Enhanced User Manual

Page 12

12

WATLOW Series 988 Enhanced Software Features

Ratio

Requirements

Ratio control requires enhanced software. Two analog inputs are required

to monitor the process, and at least one output adjusts the controlled part

of the process.

Overview

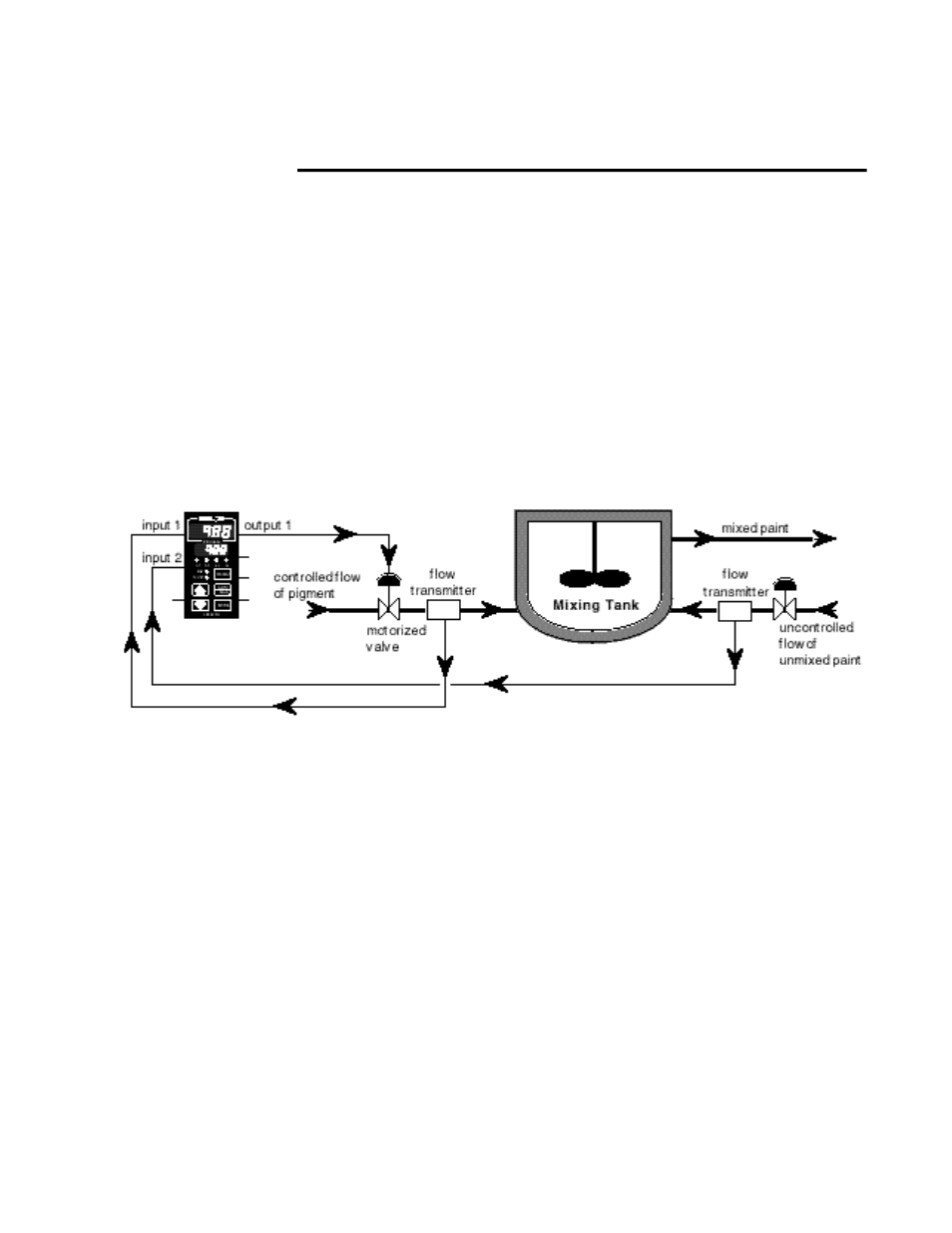

This feature allows the Series 988 to control one process as a ratio of

another process. This is especially useful in applications that mix two

materials, whether steam, paint or food ingredients.

Input 2 of the controller measures the part of the process that is either

uncontrolled or controlled by another device. The part of the process

controlled by the 988 will be maintained at a level equal to the quantity

measured at input 2 multiplied by the ratio term set by the user. Input 1

monitors the controlled part of the process.

Sample Application

Blue pigment must be added to paint at a ratio of one part per 100 to cre-

ate a mixed paint of the desired color. The uncolored paint flows into the

mixer in an uncontrolled stream that is set manually and sensed by input

2. A motorized valve controls the flow of pigment, which is monitored by

the flow sensor to input 1. The flow rate of the uncolored paint determines

the set point for the motorized valve that controls the pigment flow. If an

operator needs to change the rate of flow for the uncolored paint, the set

point will shift accordingly to maintain the correct ratio in the mixing

tank.

The application engineer set up this feature in software by choosing ratio

[rAti]

as the control [CntL] parameter in the Global Menu. The set point

value displayed was then a ratio value. He entered 0.01 to maintain an

input 1:input 2 ratio of 1:100.

Figure 9.12 - Mixing

tank with ratio con-

trol.