Dimensions, Installation, Safety information – Watlow Series 146 User Manual

Page 2: Mounting, Wiring guidelines, Mounting safety information installation

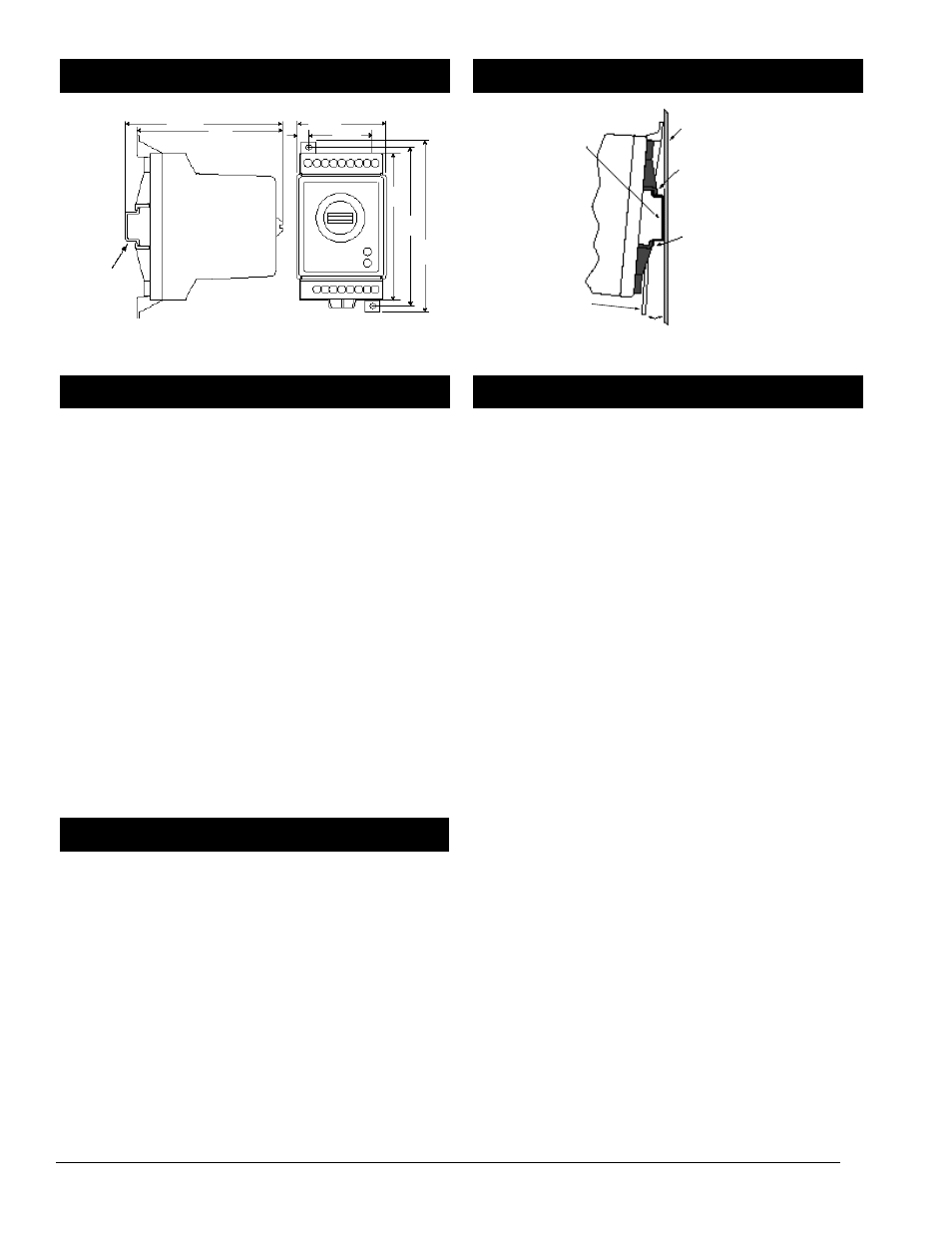

Figure 2a — Series 146 dimensions.

Sub-Panel Mounting the Series 146

NOTE: FM approval requires limit switches to be suitably enclosed

to minimize casual readjustment of set temperature.

1. Using the controller as a location template, mark both

mounting holes.

2. Drill two 5 mm (0.19 in.) diameter holes in the desired

panel location. See Figure 2a for hole locations.

3. Mount the Series 146 using two #8-32 screws.

DIN Rail Mounting the Series 146

1. Place the Series 146 upper mounting clip on the top edge

of the DIN rail. See Figure 2b on this page.

2. Press down firmly on the top front edge of the Series

146. The controller “snaps” securely onto the rail. If the

controller does not snap on, check to see if the DIN rail

is bent. Minimum clipping distance is 34.8 mm (1.37 in.),

the maximum is 35.3 mm (1.39 in.).

Removing the Series 146 from the DIN Rail

1. Place your fingers on the release lever located at the

base of the Series 146.

2. While gently pressing on the top of the case, above

Terminals 1-9, pull forward on the release lever.

Note, caution and warning symbols appear throughout this

book to draw your attention to important operational and

safety information.

A “NOTE” marks a short message to alert you to an impor-

tant detail.

A “CAUTION” safety alert appears with information that is

important for protecting your equipment and performance.

A “WARNING” safety alert appears with information that is

important for protecting you, others and equipment from

damage. Pay very close attention to all warnings that apply

to your application.

The ç symbol (an exclamation point in a triangle) precedes

a general CAUTION or WARNING statement.

The Ó symbol (a lightning bolt in a triangle) precedes an

electric shock hazard CAUTION or WARNING safety

statement.

Figure 2b — Series 146 side view mounting.

• Use the correct sensor type per the model number on the

unit sticker.

• Use the proper thermocouple or RTD polarity.

• Insulate the thermocouple mounting from the mounting

surface to prevent heat migration input errors.

• Thermocouple leads should be twisted pair wire and

routed separately from any other lines.

• In electrically noisy environments (heavy switching of

contactor, motors, solenoids, etc.) use shielded thermocou-

ple lead wire with the shield connected at the sensor end

only.

• All wiring and fusing must conform to the National

Electric Code (NEC) NFPA70 and any other locally applic-

able codes.

• Fuse the independent load voltage on the L1 (hot) side

and connect it to the common (COM) side of the relay.

ç

CAUTION: A power disconnect located near the controller is

recommended to shut down power in case of controller failure.

• Long lead lengths create electrical resistance. When using

a two wire RTD, there will be an additional error for

every 1

Ω of lead length resistance. That resistance when

added to the resistance of the RTD element, can result in

erroneous input to the temperature limit. To overcome

this problem, use a three wire RTD sensor, which compen-

sates for lead length resistance. When extension wire is

used for a three wire RTD, all three extension wires must

have the same electrical resistance. (i.e. same gauge,

copper stranded.

Wiring Guidelines

DIN Rail

Panel

Upper Mounting Clip

Lower Mounting Clip

Snap Action

Release Lever

Mounting

Safety Information

Installation

99 mm

(3.89 in.)

95 mm

(3.72 in.)

58 mm

(2.28 in.)

41 mm

(1.62 in.)

113 mm

(4.45 in.)

35 mm x 7.5 mm

Rail is not

included in

the assembly

104 mm

(4.10 in.)

96 mm

(3.75 in.)

Dimensions

2

■

Watlow Series 146 User’s Manual