Series 27 manual piloted valves with l-o-x control, Series 27 manual piloted valves with l-o-x, Control – Ross Controls RIGHT ANGLE User Manual

Page 9: L-o-x, Sensing port, Port sizes up to 2 1/2 for larger systems

www.rosscontrols.com 9

1

2

3

Y3

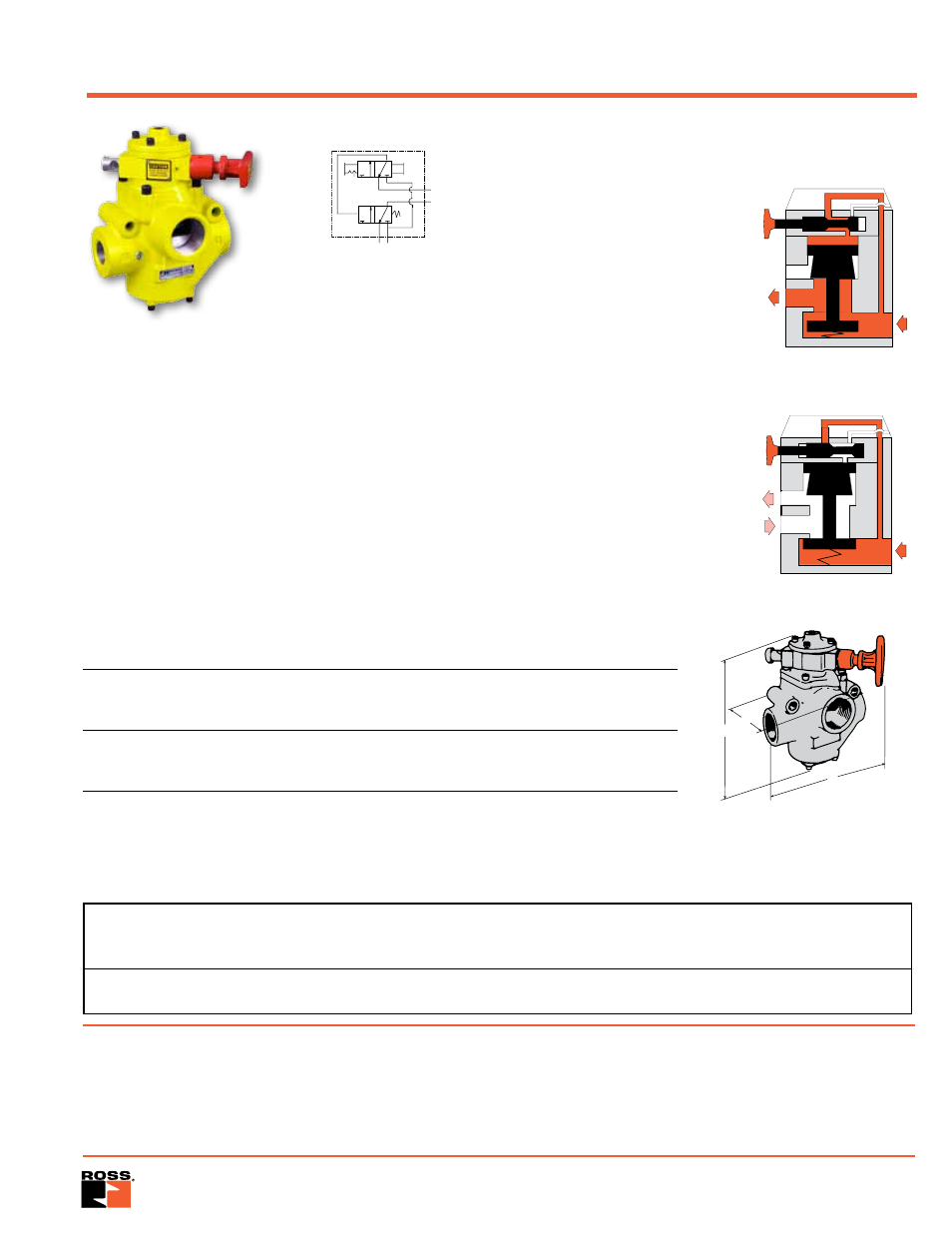

Series 27 Manual Piloted Valves with L-O-X

®

Control

Port Sizes up to 2

1/2 for Larger Systems

VALVE OPEN

With the red handle pulled out, pilot

air flows to the top of the actuating

piston, causing it to open the inlet

poppet. Supply air then flows freely

from inlet to outlet, and the exhaust

port is blocked. A detent keeps the

L-O-X

®

handle in the open position.

The handle is designed not to be

locked in the open position, thereby

allowing for quick shut-off when

necessary.

VALVE CLOSED

With a short push of the red handle

inward the flow of supply air is

blocked and downstream air is

exhausted via the exhaust port. Air

pressure on the inlet and exhaust

poppets produces a large closing

force. The L-O-X

®

valve should be

padlocked in this position to prevent

the handle from being pulled out-

ward inadvertently when potential

for human injury exists or servicing

machinery.

Following any FRL components, an energy isolation valve is usually

the first valve in the line supplying compressed air to equipment. The

energy isolation valve should provide a quick means of shutting off

the supply of air and exhausting the downstream lines.

The ROSS manual pilot L-O-X

®

valve has a large red operating handle

for high visibility. A short, full inward push of the red operating handle

closes off the flow of air, and exhausts the pressure in the downstream

line. This action is swift and doesn’t require a difficult, slow, or confusing

twisting action.

Because of the poppet construction of the main valve body, air pressure

provides the forces both to open the valve and to close it. These are

large forces so that quick response is ensured even after the valve has

been on standby for a long time.

The exhaust port is threaded for the installation of a silencer or a line

for remote exhausting.

VALVE OPERATION

Operated just like the smaller manual

L-O-X

®

valves shown on page 5. The

position of the red handle indicates

instantaneous full flow pressurizing or

exhausting capability.

1

2

3

1

2

3

A

B

C

For coordinating silencers, see page 18 (model numbers 5500A8001 and 5500A9002).

Port Size

Valve Model Avg. Cv

Dimensions inches (mm) Weight

In-Out Exh.

Number*

1 to 2 2 to 3

A

B

C

lb (kg)

1 11/2

Y2783A6006

23.0 34.0 7.4 (187)

8.6 (218)

6.4 (162)

7.0 (3.2)

11/4 11/2

Y2783A7006

30.0 32.0 7.4 (187)

8.6 (218)

6.4 (162)

7.0 (3.2)

11/2 11/2

Y2783A8016

30.0 31.0 7.4 (187)

8.6 (218)

6.4 (162)

7.0 (3.2)

11/2 21/2

Y2783A8006

68

70

8.4 (213)

10.2 (259)

6.6 (162)

15.3 (6.9)

2 21/2

Y2783A9006

70

70

8.4 (213)

10.2 (259)

6.6 (162)

15.3 (6.9)

21/2 21/2

Y2783A9016

70

71

8.4 (213)

10.2 (259)

6.6 (162)

15.3 (6.9)

STANDARD SPECIFICATIONS: For valves on this page

Ambient/Media Temperature: 40° to 175°F (4° to 80°C)..

Flow Media: Filtered air; 5 micron recommended.

Inlet Pressure:

Port sizes 1 to 2

1/2: 15 to 150 psig (1.0 to 10.3 bar).

Port sizes 1

1/2 to 21/2: 30 to 150 psig (2.1 to 10.3 bar).

*Body Paint: Yellow.

*Port Threads: NPT standard. For BSPP threads, insert a “D” after

“Y” to the model number, e.g.,YD2783C6006.

NOTE: Per specifications and regulations, these products are

defined as energy isolation devices, NOT AS EMERGENCY

STOP DEVICES.

L-O-X

®

Sensing Port

L-O-X

®

Sensing Port - Series 15 manual L-O-X

®

valves and manual L-O-X

®

valves with

EEZ-ON

®

operation are now provided with 1/8

NPT sensing ports, enabling installation of a pressure sensing device such as the Pop-Up Indicator or Pressure Switch shown below.

Standards suggest that machine design should include a method for verifying the release of energy after lockout.

The ROSS 988A30 Pop-Up Indicator is constructed for the industrial environment with a brass body and 1/8” NPT connection. It offers

360° visibility and a redundant verification feature. By pushing on the red plunger, the operator can “feel” the presence of pressure

and verify that the indicator is performing its sensing function.

The ROSS 586A86 Pressure Switch offers an electronic pressure sensing option that can be integrated into a safety monitoring system,

which confirms energy isolation throughout the circuit.