Ross Controls RIGHT ANGLE User Manual

Page 3

www.rosscontrols.com 3

CONTENTS

Page

Regulations & Standards .............................................2-3

Series 15 L-O-X

®

Valves with EEZ-ON

®

Operation ......... 4

Series 15 Manual L-O-X

®

Valves .................................5-7

Series 27 Piloted Valves with L-O-X

®

Control ............8-10

Series 27 EEX-ON

®

Valves ......................................11-12

Series 27 L-O-X

®

Valves with EEZ-ON

®

Operation ....... 13

Right-angle EEZ-ON

®

Valves ........................................ 14

Modular L-O-X

®

, Air Entry Combinations.................15-17

Accessories .............................................................18-19

Cautions ....................................................................... 19

Warranty ....................................................................... 19

Global Locations ........................................................... 20

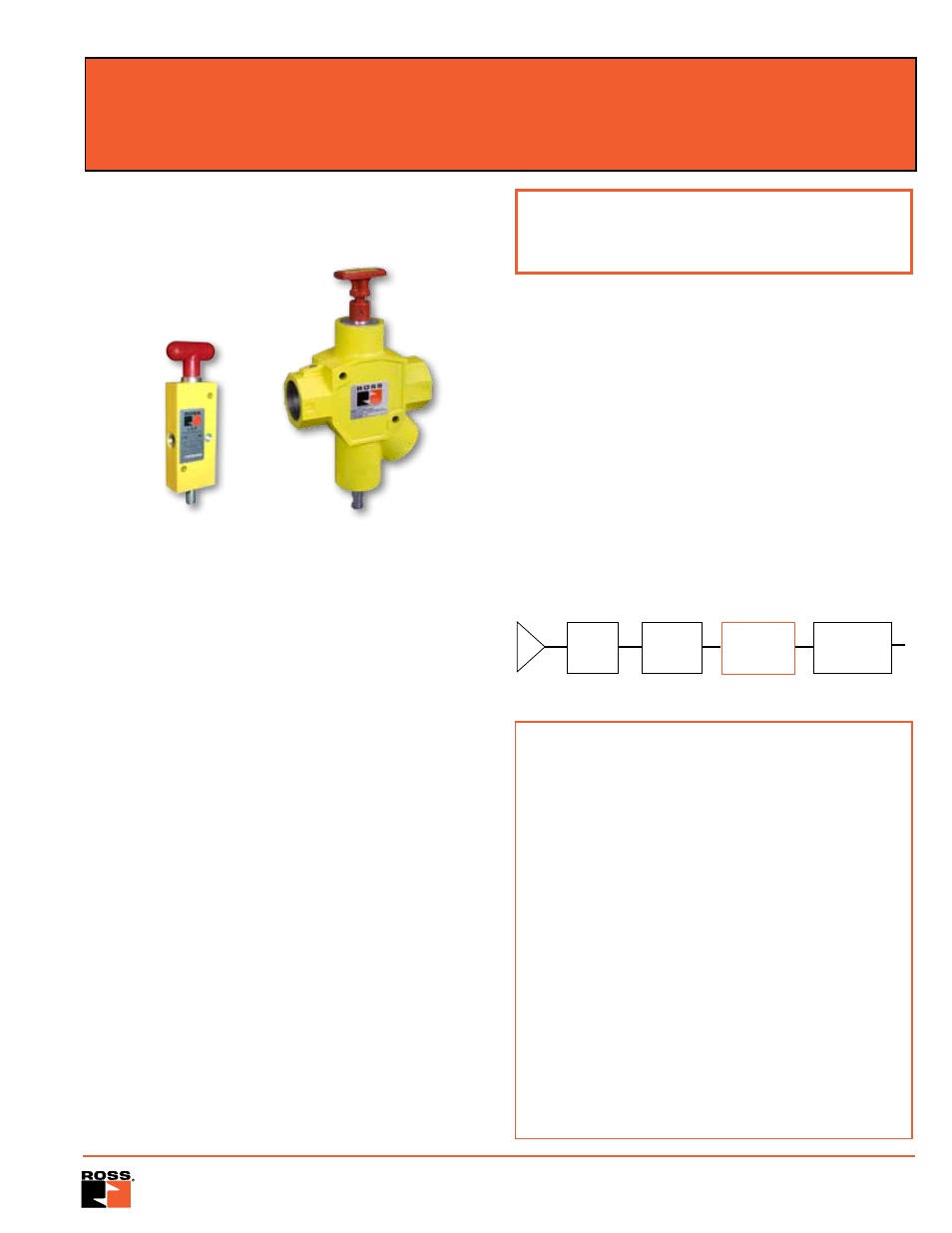

A ROSS EEZ-ON

®

valve is designed to allow a gradual buildup

of downstream air pressure before opening the line to full air

flow. This gradual pressure buildup allows cylinders and other

work elements to move slowly and more safely into their normal

working positions before full line pressure buildup is applied.

The time required for full pressure buildup is adjustable.

EEZ-ON

®

valves are available as either 2/2 (2-port, 2-position)

or 3/2 (3-port, 2-position) valves. Either type can be used in

conjunction with a L-O-X

®

valve to supply a lockout and exhaust

feature in addition to the gradual buildup of supply pressure.

The L-O-X

®

valve and EEZ-ON

®

valve functions can now also

be obtained in a combined configuration — the L-O-X

®

valve

with EEZ-ON

®

operation. In this valve, all the functions are

combined in a single valve for the most compact installation

possible. See page 4 for more details.

How Users of Pneumatic Equipment

Can Comply with OSHA Rules

ROSS EEZ-ON

®

Valves

Also Add to Plant Safety

L-O-X

®

is the simple and effective solution: The manual

L-O-X

®

valve controls air flow simply by a push of its large red

handle in or out. The valve is open when the handle is pulled

outward and air then moves freely from inlet to outlet ports. A

short inward push of the handle closes the inlet to the flow of

air and connects the outlet port to the exhaust port immediately

exhausting downstream compressed air.

For your convenience, L-O-X

®

valves are available in pipe sizes

from 1/4 to 3 inches.

If your machines aren’t already equipped with L-O-X

®

valve or

L-O-X

®

valve with EEZ-ON

®

operation valve, here are six good

reasons why they should be:

• Effectiveness: A L-O-X

®

valve not only isolates the

equipment by shutting off air supply, it exhausts stored or

residual downstream air immediately.

• Ease of Use: Air shutoff is simple; just push in the bright red

handle! There’s no turning or twisting and guessing whether

the valve is completely open – it’s automatic!

• Locking protection: L-O-X

®

valves are designed to allow

secure lock-out upon shutdown, using standard padlocks.

• Reliability: Special Teflon seals help ensure “shift-ability”

even after long periods of non-use.

• Efficiency: Large exhaust ports provide rapid exhaust of

downstream air and are threaded for silencers or remote

exhaust lines.

• User Confidence: Three-way valve design opens the system

to atmosphere during shut-down. Any leakage past the spool

is exhausted faster than it can build up.

And now, with ROSS L-O-X

®

valves with EEZ-ON

®

operation,

you get even more value. Combining the lockout function of

ROSS L-O-X

®

valve with the gradual start-up capability of the

EEZ-ON

®

, the L-O-X

®

with EEZ-ON

®

operation, gives you two

safety-related functions in one convenient unit.

Here’s how our

famous L-O-X

®

valve helps...

FRL

L-O-X

®

Valve

EEZ-ON

®

Valve

Operating

Valve