Val-Matic Cam-Centric Plug Valve User Manual

Page 5

5

FLANGED ENDS: Flanged valves should be mated

with flat-faced pipe flanges equipped with resilient

gaskets. When ring gaskets are used, the bolt material

should be ASTM A307 Grade B of SAE Grade 2

Carbon Steel. Higher strength bolts may only be used

with full-face gaskets.

The valve and adjacent piping must be supported and

aligned to prevent cantilevered stress on the valve.

Lower valve into line using slings or chains around the

valve body. Lubricate the flange bolts or studs and

insert them around the flange. Lightly turn bolts until

gaps are eliminated.

The torquing of the bolts should then be done in

graduated steps using the cross-over tightening

method. Recommended lubricated torques for use

with resilient gaskets (75 durometer) are given in Table

2. If leakage occurs, allow gaskets to absorb fluid and

check torque and leakage after 24 hours. Do not

exceed bolt rating or crush gasket more than 50

percent of its thickness.

TABLE 2. FLANGE BOLT TORQUES

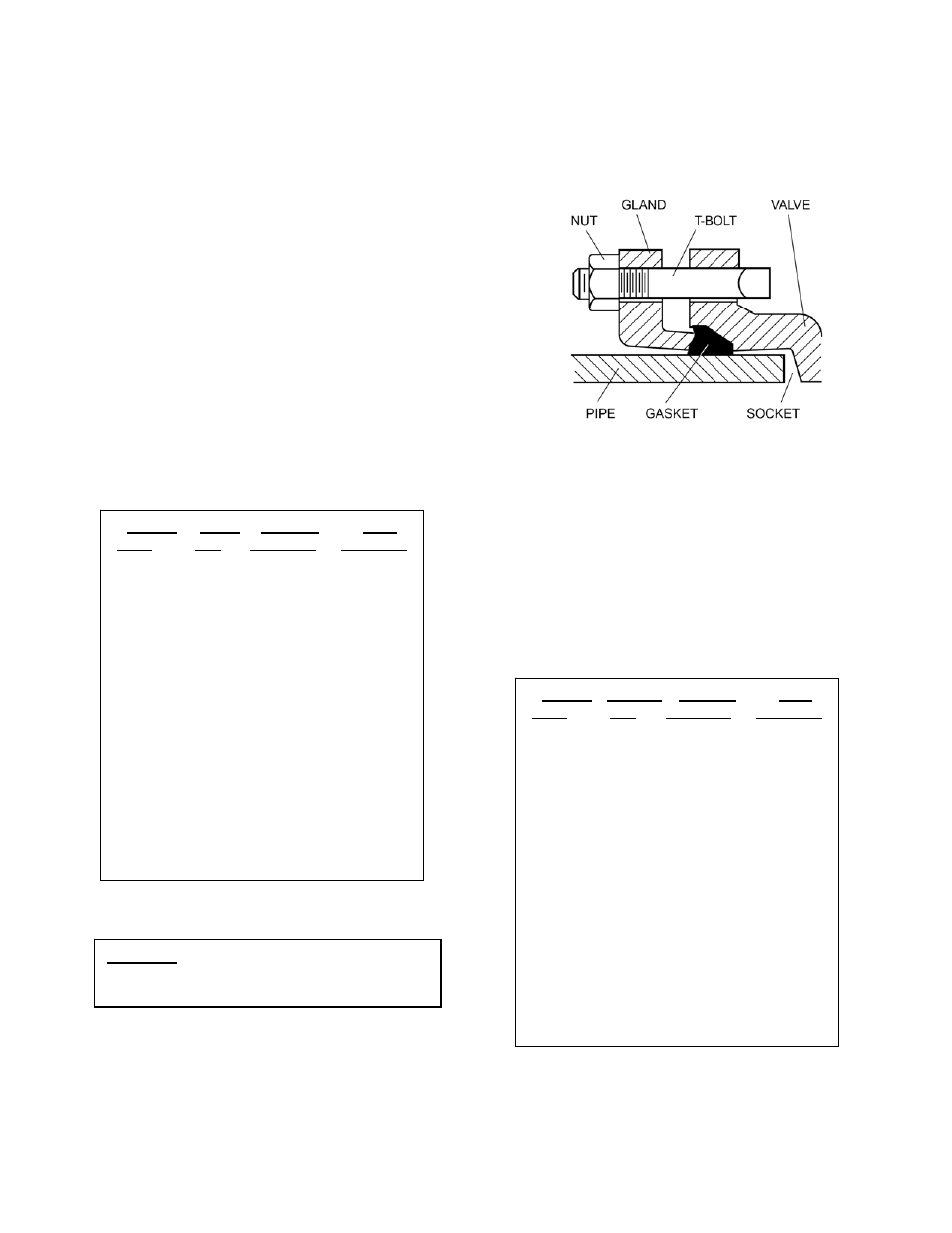

MECHANICAL JOINT ENDS: Clean ends of mating

pipe and valve sockets with soapy water (Figure 7).

Place lubricated gasket and retainer gland over pipe

end prior to installing valve. Install valve socket over

pipe. Press gland and gasket toward valve until gasket

is evenly set into valve socket.

FIGURE 7. MECHANICAL JOINT INSTALLATION

Insert T-bolts in valve flange and hand tighten nuts.

Torque nuts in four graduated steps using the cross-

over tightening method without exceeding the torque

listed in Table 3. Maintain an equal gap between the

gland and the face of the valve at all points around the

socket.

If a tight connection is not achieved, then the joint

should be disassembled, thoroughly cleaned, and

reassembled. Over-tightening may cause damage to

the valve or gland.

TABLE 3. MECHANICAL JOINT NUT TORQUES

VALVE BOLT RECOM

MAX

SIZE DIA TORQUE

TORQUE

(in)

(in) (ft-lbs)

(ft-lbs)

3

5/8 25

90

4

5/8 30

90

6

3/4 30

150

8

3/4 40

150

10

7/8 45

205

12

7/8 65

205

14

1

80

300

16

1

90

300

18

1 1/8 100

425

20

1 1/8 120

425

24

1 1/4 150

600

30

1 1/4 175

600

36

1 1/2 175

1000

42

1 1/2 200

1000

48

1 1/2 250

1000

CAUTION: The use of raised-face flanges

or excessive bolt torque may

damage valve flanges.

VALVE T-BOLT RECOM

MAX

SIZE DIA TORQUE

TORQUE

(in)

(in) (ft-lbs)

(ft-lbs)

3

5/8 45

60

4

3/4 75

90

6

3/4 75

90

8

3/4 75

90

10

3/4 75

90

12

3/4 75

90

14

3/4 75

90

16

3/4 75

90

18

3/4 75

90

20

3/4 75

90

24

3/4 75

90

30

1

100

120

36

1

100

120

42

1-1/4 75

150

48

1-1/4 75

150