Val-Matic Cam-Centric Plug Valve User Manual

Page 10

SIZE

TORQUE

(FT-LBS)

1/2"-13

45 - 75

5/8"-11

100 - 150

3/4"-10

150 - 250

7/8"-9

200 - 350

1"-8

300 - 500

1 1/8"-7

450 - 700

1 1/4"-7

650 - 1000

1 1/2"-6

750 - 1100

REASSEMBLY

All parts must be cleaned and gasket surfaces should

be cleaned with a stiff wire brush in the direction of the

serrations or machine marks. Worn parts, gaskets and

seals should be replaced during reassembly.

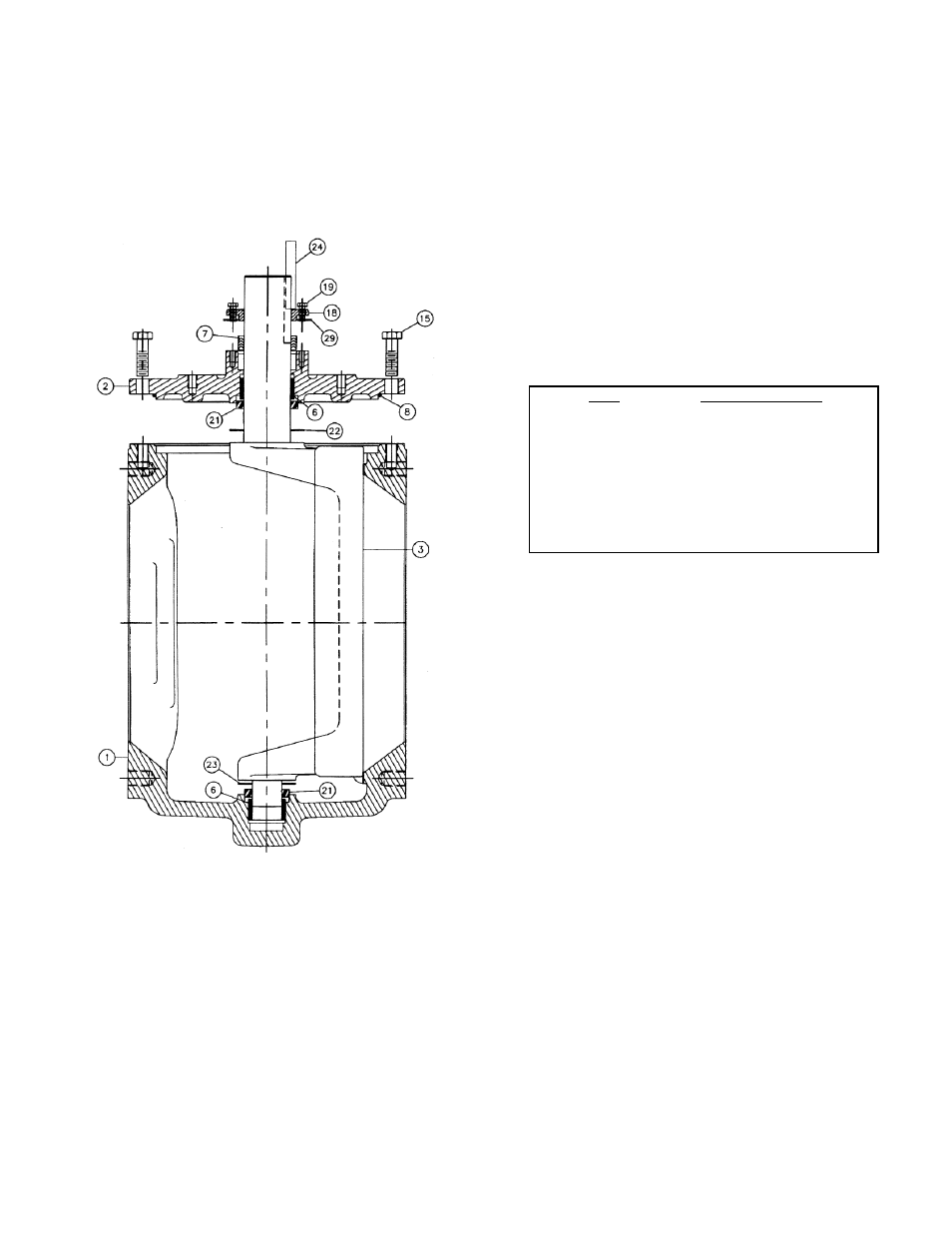

FIGURE 14. PLUG VALVE PARTS

1. Press new bearings (6) into cover and body with

round, flat bar 1/4" below inside surfaces of body

(1) and cover (2).

2. Install cover seal (8) over cover lip.

3. Apply thin film of FDA silicone grease such as

Dow Corning #7 to plug rubber surface. Place

stainless steel thrust bearing (23) over lower end

of plug, Teflon bearing (22) over the upper end.

Install grit seals (21) over the shafts of the plug.

4. Carefully place plug into the body (1) and insert

lower plug shaft into bottom bearing (6). Plug (3)

should be in the open position. Install cover (2)

over plug shaft and into recess in body. Align

match marks between body and cover (2). Torque

cover bolts (15) per Table 6 in 3-4 increments

using the cross-over tightening method.

TABLE 6. TIGHTENING TORQUES

5. Lubricate ID and OD of packing set with FDA

grease and install in packing bore one ring at a

time taking care to keep lips pointing down toward

plug. Reinstall follower, gland bolts, and 2 shims

per bolt.

NOTE: If valve has friction assembly with direct

nut actuator, follow Friction Adjustment procedure

on page 6.

6. Insert key (24) into shaft and place actuator over

valve. Reinstall actuator mounting bolts and

torque per Table 6. Install cover on actuator.

7. Apply power to actuator and cycle valve. Apply

pressure to valve and check for cover and shaft

leakage. Tighten bolts as necessary. Adjust

packing if necessary.

8. If valve does not shut off tight, adjust the closed

position stop as described on page 6 under

“Closed Position Adjustment.”