3valve construction – Val-Matic Cam-Centric Plug Valve User Manual

Page 3

3

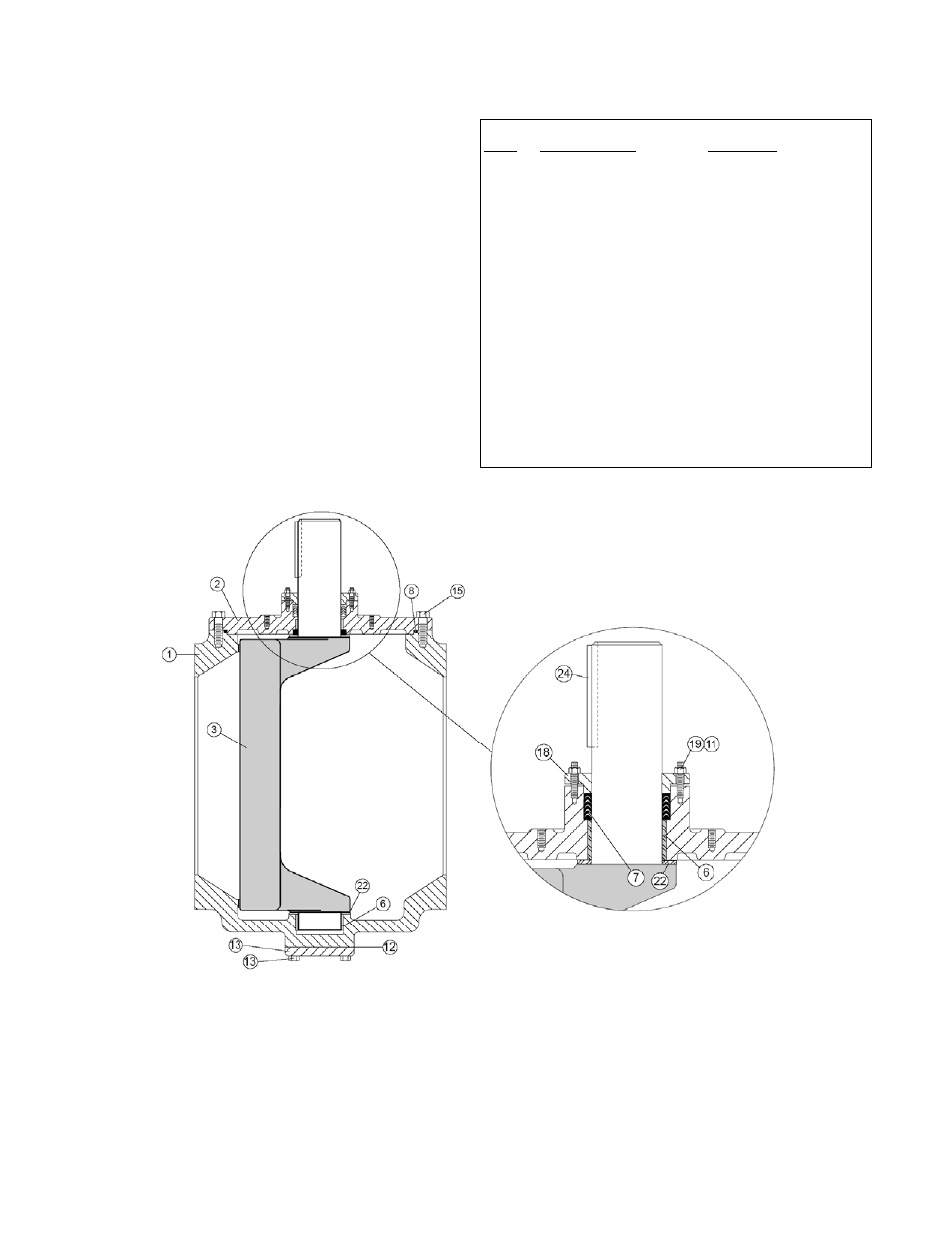

VALVE CONSTRUCTION

The standard Cam-Centric

®

Plug Valve is constructed

of rugged cast iron with a welded nickel seat and

permanently lubricated bearings. See the specific

Materials List submitted for the order if other than

standard cast iron construction. The details of

construction are illustrated in Figure 3.

The body (1) is available with flanged or mechanical

joint ends for connection to the pipeline. The valve is

designed to be serviced in-line by removing the cast

cover (2). The quarter-turn plug (3) is guided by sleeve

bearings (6) located in the cover and lower boss in the

body. Grit-Guard seals (21) are located at the bottom

of the bearings (6) to prevent abrasive material from

wearing the bearing. Leak-tight closure is made when

the rubber-coated plug (3) is rotated into the nickel

seat on the “SEAT END” of the body.

TABLE 1. STANDARD PLUG VALVE PARTS LIST

FIGURE 3. STANDARD PLUG VALVE CONSTRUCTION

ITEM DESCRIPTION

MATERIAL

1

Body

Cast Iron with Overlay

Welded Nickel Seat

2

Cover

Cast Iron

3

Plug*

Cast Iron with

Resilient

Facing

6

Bearings*

316 Stainless Steel

7

V-Type Packing*

Buna-N

8

Cover Seal*

Buna-N

15

Cover Bolt

Alloy Steel, Gr 5

18

Packing Follower

Cast Iron

19

Follower Bolt

Alloy Steel, Gr. 5

21

Grit-Guard*

Buna-N

22

Thrust Bearing*

Teflon

23

Thrust Bearing*

316 Stainless Steel

24

Key

Carbon Steel

29

Shims

304 Stainless Steel

*RECOMMENDED SPARE PART