Val-Matic Cam-Centric Plug Valve User Manual

Page 2

2

CAUTION: Do not use valve for line testing at

pressures higher than nameplate rating or

leakage and damage to valve may occur.

VAL-MATIC'S CAM-CENTRIC PLUG VALVE

OPERATION, MAINTENANCE AND INSTALLATION

INTRODUCTION

The Cam-Centric

Plug Valve has been designed to

give years of trouble-free operation. This manual will

provide you with the information to properly install and

maintain the valve to ensure a long service life. The

valve is an eccentric, resilient seated, quarter-turn plug

valve capable of handling many types of fluids

including fluids with suspended solids. The Size,

Cold Working Pressure (CWP), Actuator Rating, and

Model No. are stamped on the nameplate for

reference.

The "Cold Working Pressure" is the non-shock

pressure rating of the valve at 150

o

F. The valve is not

intended as a block valve for line testing above the

valve rating. The “Actuator Rating” is the pressure that

was used to size the actuator for operating conditions

and may be less than the “Cold Working Pressure”.

Because the valve is eccentric, the valve may have a

different actuator rating for reverse and direct pressure.

If the valve is operated at pressures higher than the

actuator ratings, the valve may be difficult to operate or

leak.

RECEIVING AND STORAGE

Inspect valves upon receipt for damage in shipment.

Unload all valves carefully to the ground without

dropping. Do not lift valves with slings or chains

around the actuator or through the seat area.

Valves should remain crated, clean and dry until

installed to prevent weather-related damage. For long

term storage greater than six months, the valve must

remain open and the rubber surfaces of the plug

coated with a thin film of FDA approved grease such

as Dow Corning # 7. Do not expose plug to sunlight or

ozone for any extended period.

DESCRIPTION OF OPERATION

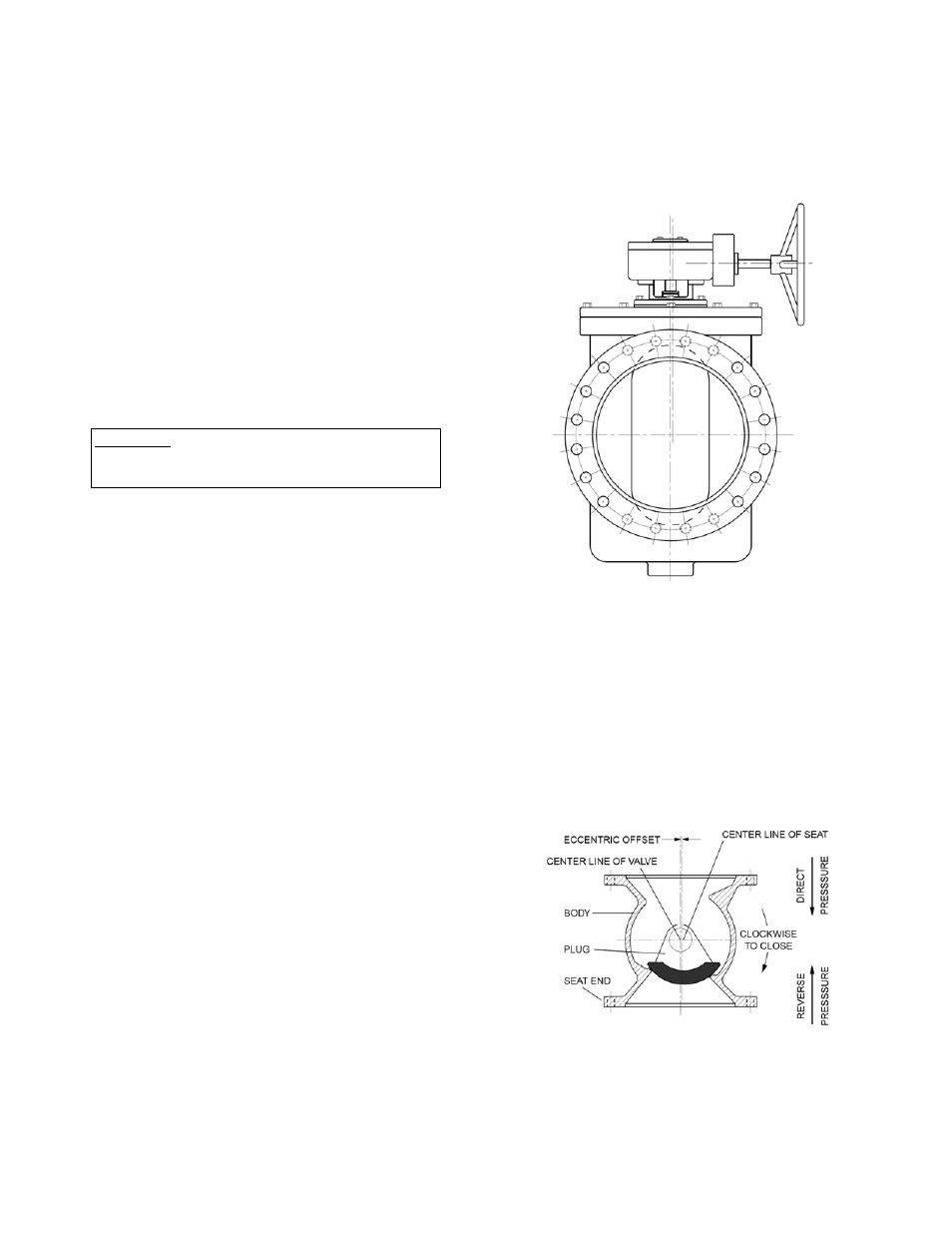

As shown in Figure 2, the valve consists of a body and

quarter-turn plug that is offset from the seat centerline.

FIGURE 1. PLUG VALVE WITH GEAR ACTUATOR

The eccentric offset causes the plug to lift and rotate

off the seat simultaneously to reduce seat friction and

wear during operation. Direct Pressure pushes the

plug into the seat and Reverse Pressure pushes the

plug away from the seat. The valve can be operated

with a direct nut, lever, or gear actuator. The gear

actuator as shown in Figure 1 requires multi-turn input

on a 2” square nut, handwheel, or chainwheel. The

valve can also be automated with power actuators

such as an electric motor or hydraulic cylinder.

FIGURE 2. PLUG VALVE TERMS