Val-Matic Tilted Disc Check Valve User Manual

Page 14

13

OPTIONAL TOP DASHPOT (Cont’d)

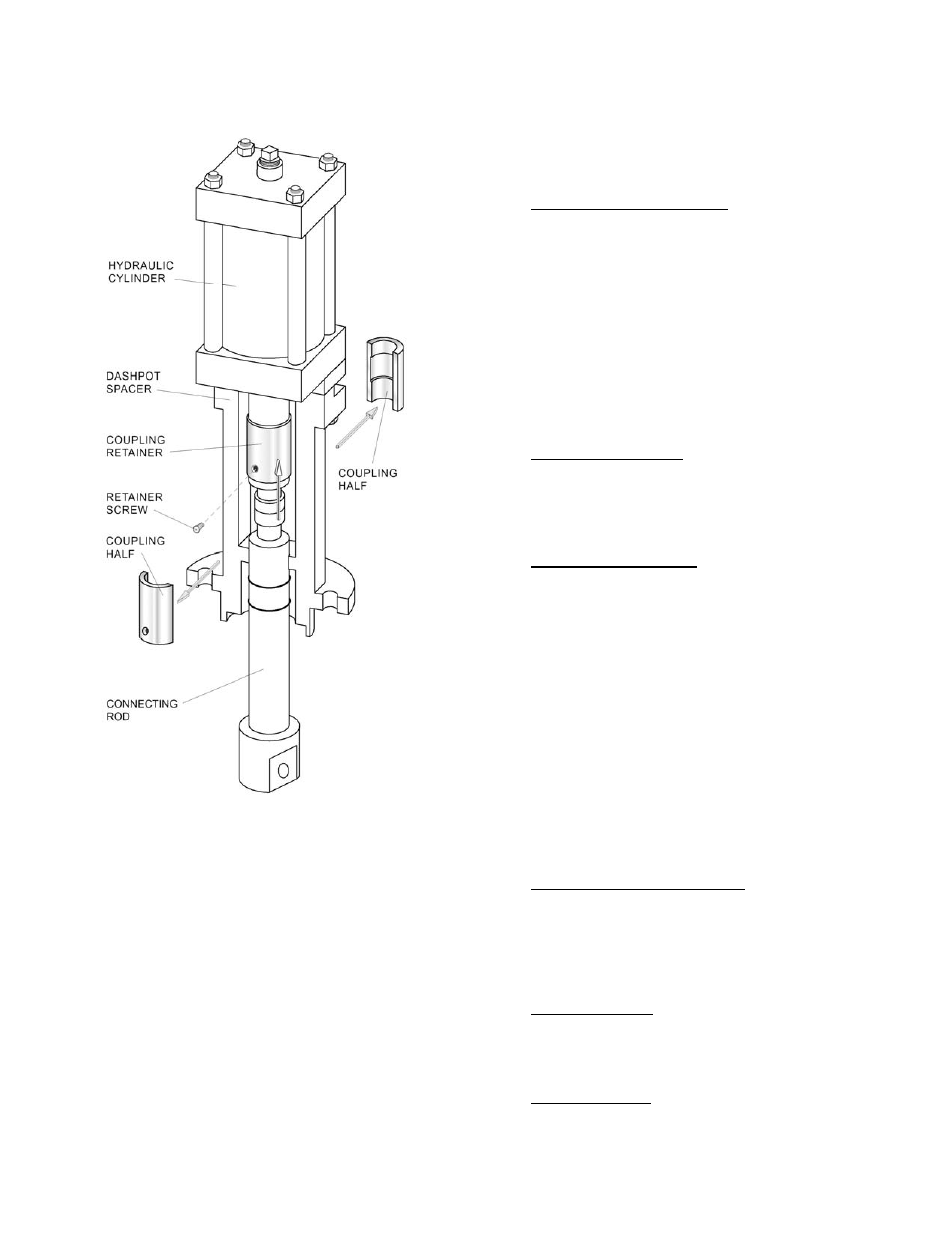

Figure 8. Quick Change Coupling

The Quick Change Coupling provides for easy

removal and maintenance of the dashpot assembly

while the check valve is under pressure. The

coupling also provides a self-aligning connection

which prolongs the life of the seals and bushings in

the cylinder and dashpot assembly.

The coupling is formed in two half-sections. The

sections are joined together around the ends of the

cylinder rod and the connecting rod and secured

with an outer slip-type coupling retainer.

TROUBLESHOOTING VALVE WITH TOP

MOUNTED OIL DASHPOT: The top mounted oil

dashpot is linked directly to the disc. Flow control

valves (38) control the opening and closing speeds

in the 5-30 second range. The last 10% of closure is

also controlled by the cylinder cushion control.

1. Valve Does Not Close Fully: Check air pressure

in reservoir; should be at least 20% of the water

system pressure on the downstream side of the

valve or 10 psig minimum. The pressure can be

increased until the valve closes but the opening

stroke may be reduced. Add grease to dashpot

fitting (23). Open lower flow control valve (38)

further to allow greater oil flow. Readjust flow

control valve until slam is diminished. A

differential pressure across of the disc of at least

50 psig is typical for dashpot valves. If the

pressure is lower, the dashpot is probably not

needed and may interfere with valve operation.

2. Valve Slams Closed: Dashpot should prevent

slamming by controlling the valve closure.

Throttle down the bottom flow control valve (38)

to slow down valve closure. If problem persists,

check oil level in unit per the Instruction Manual.

3. Valve Does Not Open: Open top flow control

valve (38) fully counterclockwise. Check pressure

differential across disc; upstream pressure must

be greater than downstream pressure. Verify that

downstream shutoff valve is open and there is no

line blockage. Add grease to valve and dashpot

grease fittings (23). Lower pressure on air tank

(pressure should be 20% of water system

pressure). Pressure can be temporarily reduced

to 0 psig to assist in valve opening. Drain the

pipe on both sides of the valve, remove

inspection cover (13), and inspect disc ring (8)

and seat ring (10) for damage or wedged debris.

If debris is wedged in the valve, it may de

necessary to jack open the disc with a hydraulic

jack. See “Inspection of Valve” on page 1 of this

guide for further information.

4. Noisy Operation or Vibration: Flow noise is

normal. Loud flow noise similar to hammering

may be cavitation from dropping high pressures

across valve during opening and closing. Open

flow control valves (38) to provide shorter

operating times.

5. Pump Backspins: Valve is closing too slowly.

Open bottom flow control valve (38) further. If

surges in the pipeline result, surge relief devices

on the pipeline probably need attention.

6. Pressure Surges: Throttle down bottom flow

control valve (38) further to increase closing time.