SaltDogg WB200B v.2 User Manual

Page 11

11

TM

17. Double check that all hardware is tight and the

drive system turns properly (it should feel a bit snug).

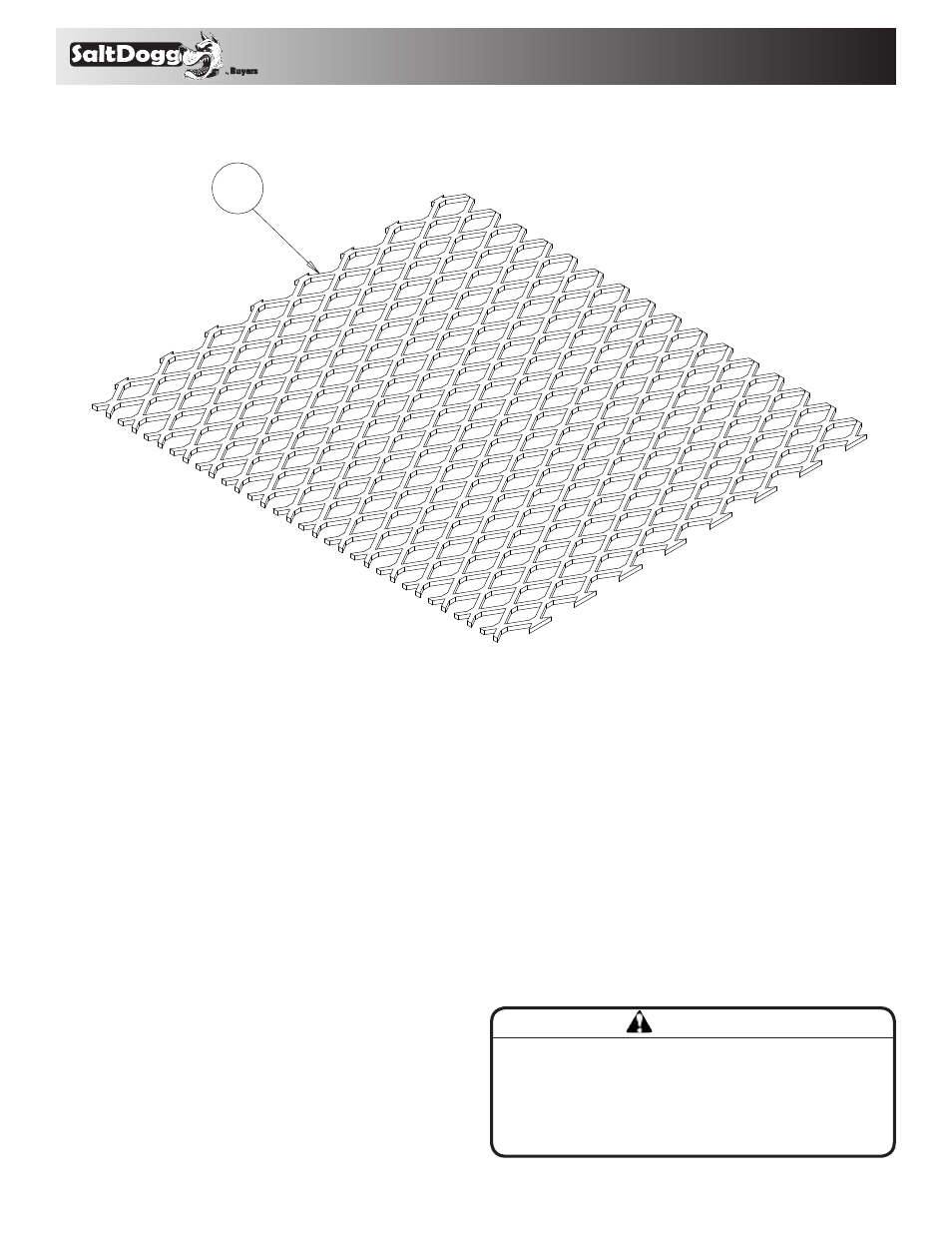

18. Place the screen(16) inside the hopper.

Operation

1. Before filling Hopper, ensure that the Restrictor Plate

is fully closed and the Screen is in place.

2. Move and tighten the stop bolt to the desired setting.

3. Add material and place rain cover over hopper if

desired.

4. Begin moving forward with the spreader.

5. Pull the Control Handle back to the stop bolt to open

Restrictor Plate and allow material to flow.

6. Before stopping, push the Control Handle fully for-

ward to stop flow.

Maintenance

1. The Hopper and Spinner should be completely emp-

tied and cleaned before storage.

2. The Spreader should be washed and dried before

storage.

16

3. Check that the Restrictor Plate and Linkage move

freely. Clear out any debris between the Restrictor Plate

and the Hopper.

4. Check that there is no debris in the Gears and that

they move freely.

5. Check torque of all fasteners on a monthly basis.

Operation Notes:

1. The spreader is designed to be operated at a brisk

walking pace. Walking slower or faster will alter the

distribution pattern and amount of the material, as will

the moisture content of the material and other environ-

mental factors.

2. Grease may be applied to the Pinion and Large Drive

Gear as desired.

CAUTION

When filling hopper, make certain there are no

large objects within the material. Objects larger

than the openings in the Screen may cause the

spreader to clog or even damage the drive system.

Never leave material in the hopper when not in use.