Rapid-Air CABINET REEL WITH DISPLAY KEYPAD User Manual

Page 14

14

INTRODUCTION

The RAMM Full Wave Solid State DC Motor Speed Control represents the latest state of the

art design achievable through modern technology.

Features Include:

Integrated Circuitry

Used to control and amplify command and reference levels with both closed and open loop

feedback to provide superior motor regulation. (Speed changes due to load, line voltage, or

temperature variations are held to minimum levels).

High Quality Components

Selected and tested for proven dependability.

Transient Protection

Used to prevent failure of the power bridge circuit caused by voltage spikes on the AC line.

High Reliability

When used in accordance with instructions in this manual, the RAMM will provide years of

trouble free operation.

A. Initial Setup and Wiring

General Instructions

1. Install proper size Plug-In Horsepower Resistor.

(see table 2)

2. The RAMM can be connected to a standard 120V or 240V 50/60 Hz AC line (be

sure the AC input voltage corresponds to the control voltage rating and the motor rat

ing). (e.g. 90-130 VDC motor on 120VAC and 180 VDC motor on 240 VAC)

3. Follow the recommended supply wire sizes as per table 3.

4. Follow the NEC and other electrical codes that apply.

CAUTION: SEPARATE BRANCH PROTECTION MUST BE PROVIDED ON 240V

CIRCUITS.

5. Connect control in accordance to connection diagram.

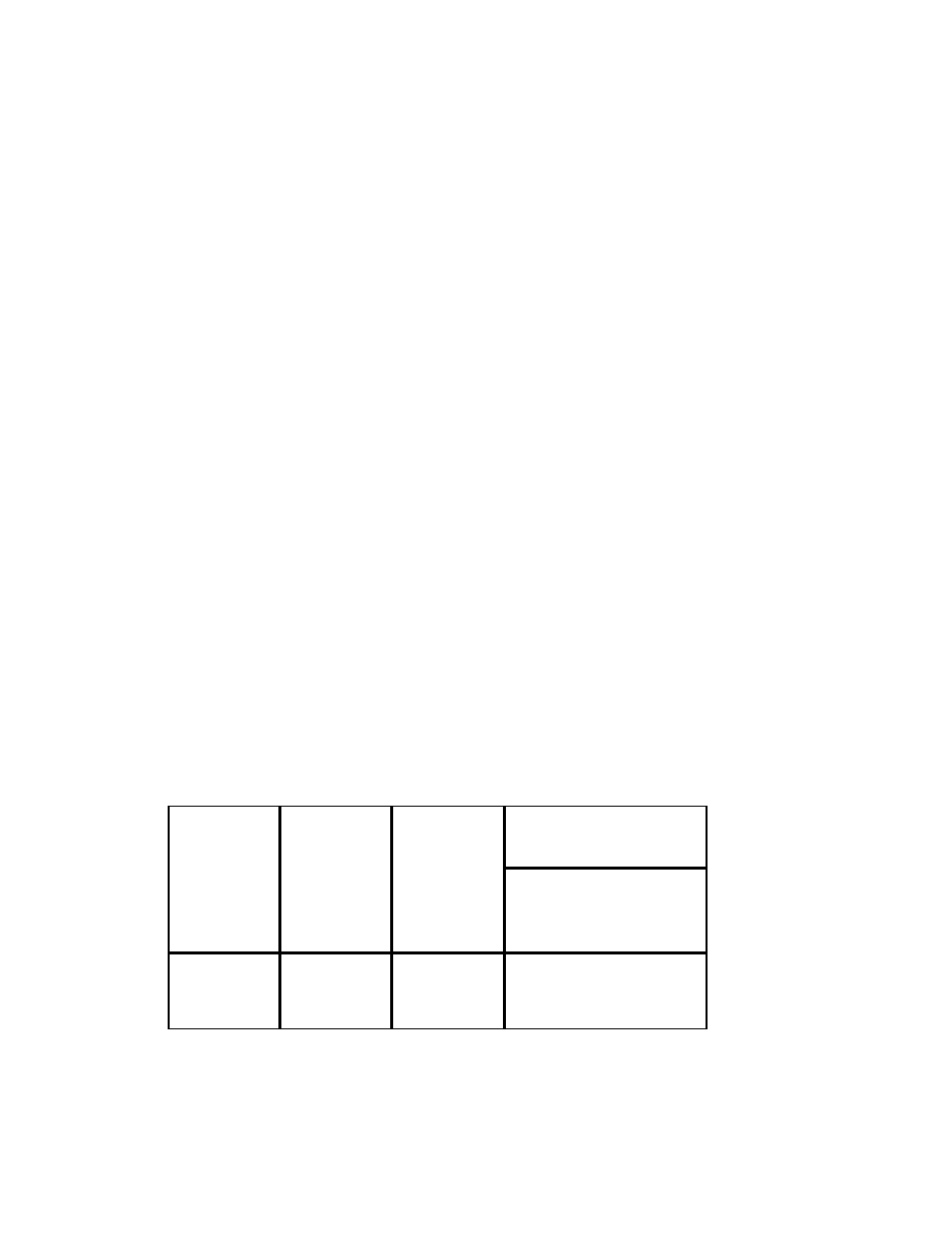

TABLE 3. MINIMUM SUPPLY WIRE SIZE REQUIREMENTS

*Maximum recommended wire size

MAX.

MOTOR

AMPS

(DC AMPS)

MAX.

MOTOR

HP

90V

MAX.

MOTOR

HP

180V

MINIMUM WIRE SIZE

(AWG) Cu only

MAX. MAX.

MOTOR MOTOR

RUN RUN

6.0

12.0

16.0

1/2

1

1 1/2

1

2

3

16 14

14 12*

12 12