Programming procedure – Rapid-Air SERVO FEED: 100C, 100D series User Manual

Page 14

Operator Input Terminal – Programming Procedure – Standard Software

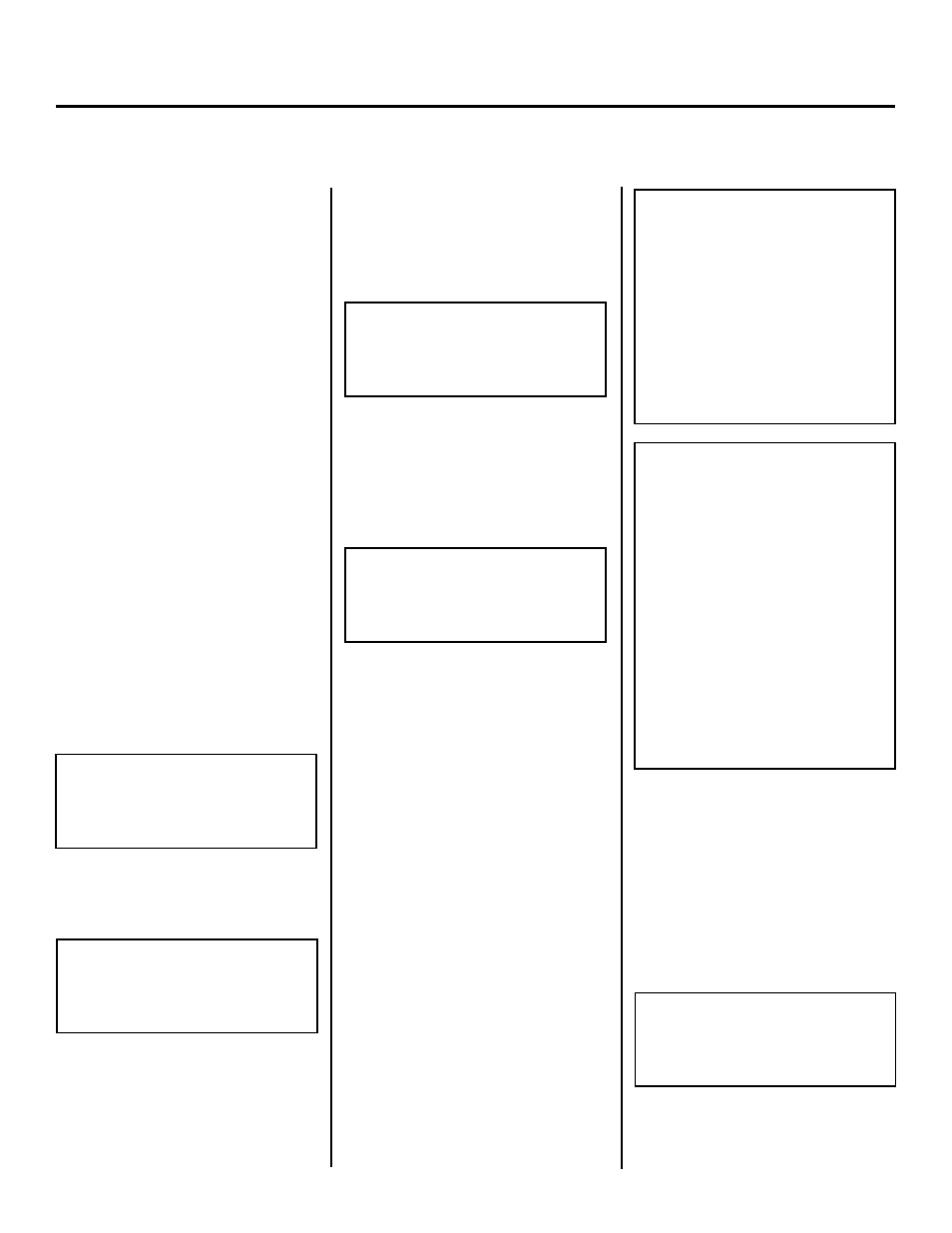

PROGRAmmING PROCEDURE

The intent of this section is to familiar-

ize the operator with the program

flow and what to expect with every

keypress. Each screen on the display

will be reviewed with special

comments to help clarify what is

being asked on the screen. The

program flow is broken down into

5 sections with the main menu being

the home postion. Reviewing the flow

chart in the back of this manual will

help in understanding the sections.

SECTION1 —-

F1=JOB ENTRY

SECTION2 —-

F2=MANUAL MODE

SECTION3 —-

F3=AUTOMATIC

SECTION4 —-

F4=REVIEW JOB PARAMETERS

SECTION 5 —-

RAMP=ADJUST ACCELLERATION

AND DECELLERATION

The first screen to be displayed on the

operator terminal will look like this

RAPID-AIR CORPORATION

4601 KISHWAUKEE STREET

ROCKFORD, IL 61109

815-397-2578

After a few seconds, the display will

clear and the following display will

appear:

MAIN MENU

F1=JOB F2=MANUAL

F3=AUTOMATIC CYCLE

F4=REVIEW PARAMETERS

SELECT F1=JOB #

The first step in programming the

servo feed is to select a job number

which will be used to store the

parameters the operator inputs or

recall the parameters which have

been previously loaded into the servo

controller program. When the

operator selects F1 on the keypad,

the screen will change to:

JOB SELECTION MENU

ENTER JOB NUMBER=XXX

PRESS F4 KEY AFTER

CORRECT # IS ENTERED

The operator must enter a 2 digit num-

ber before proceeding to any other

function. If the job number the opera-

tor has entered has been previously

stored in memory, or entering a new

job, the following display will appear:

JOB NUMBER= XXX

F1=PROGRAM PARAMETERS

F2=FEED ADVISOR-CACL

F4=DON’T ALTER VALUES

If entering in a new job then select

(F2) feed advisor first as Rapid-Air can

preset the Accel/Decel & max speed

according to the feed length, feed arc

and spm entered.

The job number screen displays (3)

choices for the operator. In the first

choice, F1=Program parameters, the

operator can enter or change the

pilots, feed length, strokes per minute

that the press is running and speed of

the material movement. In the second

choice, F2=Feed Advisor-Calc, the

operator can enter or change the pilots,

feed length, strokes per minute that

the press is running and feed arc (free

travel of the press in which the feed

can move material without a problem).

This then calculates the optimum

speed of the material movement. The

third choice, F4=Exit, puts the job num-

ber entered in memory for running at

this time. If F1 or F2 was selected one

of the following displays will appear:

MANUAL PROG--JOB #=XX

LGTH=XXX.XXX SPM=XXX

PILOTS=X %SPEED=XXX

ACC/DEC=XXX% F4=EXIT

Input or change data at

curser. When complete, press

F4 to exit. Fault window

will appear if feed length

is too long for SPM.

FEED ADVISOR JOB#=XX

LGTH=XXX.XXX SPM=XXX

PILOTS=X FEED ARC=XXX

F4=EXIT FEED ADVISOR

Input or change data at

curser. When complete, press

F4 to exit. Fault window

will appear if feed length

is too long for SPM. Feed

arc is “press free travel” for

feeding material. Minimum

arc=10, max=300 degrees.

The % of speed is then

automatically calculated.

*Use the manual program parameters

to massage the parameters or to

check what the actual feed speed

and accel/decel percents are.

This is the fault window that is

displayed if the feed length and

strokes per minute are not within

minimum parameters.

FEED PARAMETER OUT

OF RANGE. THE LENGTH

IS TOO LONG FOR FEED

ARC OR SPM F4=NEXT

F4=Next this command returns to

the previous screen so that the new

parameters can be entered.